Process method for extracting and separating rear earth without saponification

A process method, a saponification-free technology, applied in the direction of improving process efficiency, etc., can solve problems such as environmental pollution, high cost, and difficult treatment, and achieve the effects of reducing production costs, avoiding the generation of NH4+-containing wastewater, and avoiding a large amount of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

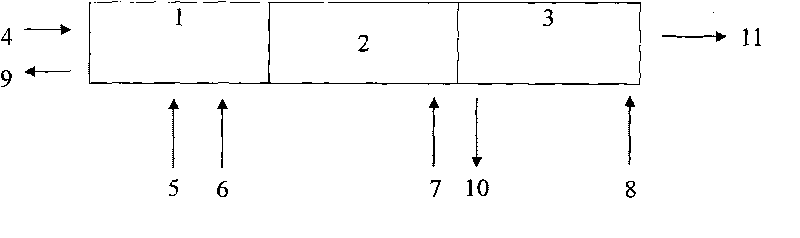

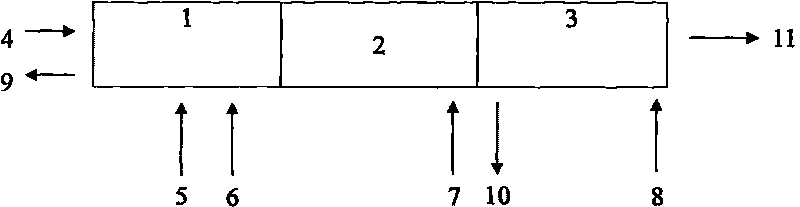

[0027] Use P507 extractant to separate impurities such as Ca and Mg in the yttrium chloride feed liquid, extract and separate 99.999% yttrium chloride, and the extraction tank is a production example of 650L.

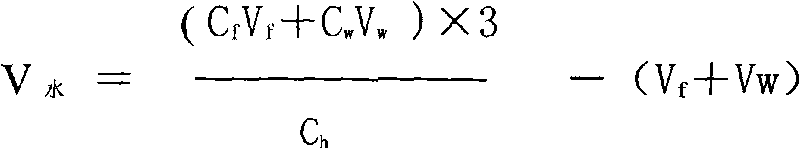

[0028] According to the method of the present invention, the dilution with water replaces the saponification of ammonia water in the extraction process.

[0029] Set the hydrochloric acid concentration value C in the raffinate 9 h Less than 0.65N.

[0030] The flow rate and concentration of the objects entering the tank are as follows:

[0031] P507: Flow V S =150L / min, concentration C s =1.3-1.5M;

[0032] YCl 3 Feed liquid: flow V f =40.9L / min, concentration C f =0.4M;

[0033] Lotion: flow rate V W =1.1L / min, concentration C W = 1.5M;

[0034] Water: flow V 水 =41L / min;

[0035] Acid reflux: Flow V 反 =14L / min, concentration C 反 = 4.5M.

[0036] The flow rate and concentration of the objects out of the tank are as follows:

[0037] Raffinate: Flow V 余...

Embodiment 2

[0043] Use P204 to fully remove the rare earth in the rare earth sulfuric acid feed solution, and use HCl back extraction to convert it into high-concentration rare earth chloride. The extraction tank is a production example of 800L.

[0044] Set the concentration value C in the raffinate 9 h Less than 0.3N.

[0045] The flow rate and concentration of the feed objects are as follows:

[0046] P204: Flow V S =150L / min, concentration C s =1.2-1.5M;

[0047] RE 2 (SO 4 ) 3 Feed liquid: flow V f =81.8L / min, concentration C f =0.2M;

[0048] Lotion: flow rate V W =1.1L / min, concentration C W = 1.5M;

[0049] Water: flow V 水 =97.1L / min;

[0050] Acid reflux: Flow V 反 =14L / min, concentration C 反 = 4.5M.

[0051] The flow rate and concentration of the objects out of the tank are as follows:

[0052] Raffinate: Flow V 余 =180L / min, acidity nearly 0.3M;

[0053] Product RECl 3 Feed liquid: flow V 产 =11.6L / min, concentration C 产 = 1.4M;

[0054] Back extraction blank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com