Waste treatment method for gas-phase method quartz product manufacturing process and waste treatment method for optical fiber perform manufacturing process

A technology for product manufacturing and waste treatment, applied in separation methods, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of large number and troubles of fiber optic enterprises, and achieve reduced investment, high generation rate, and zero system discharge. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

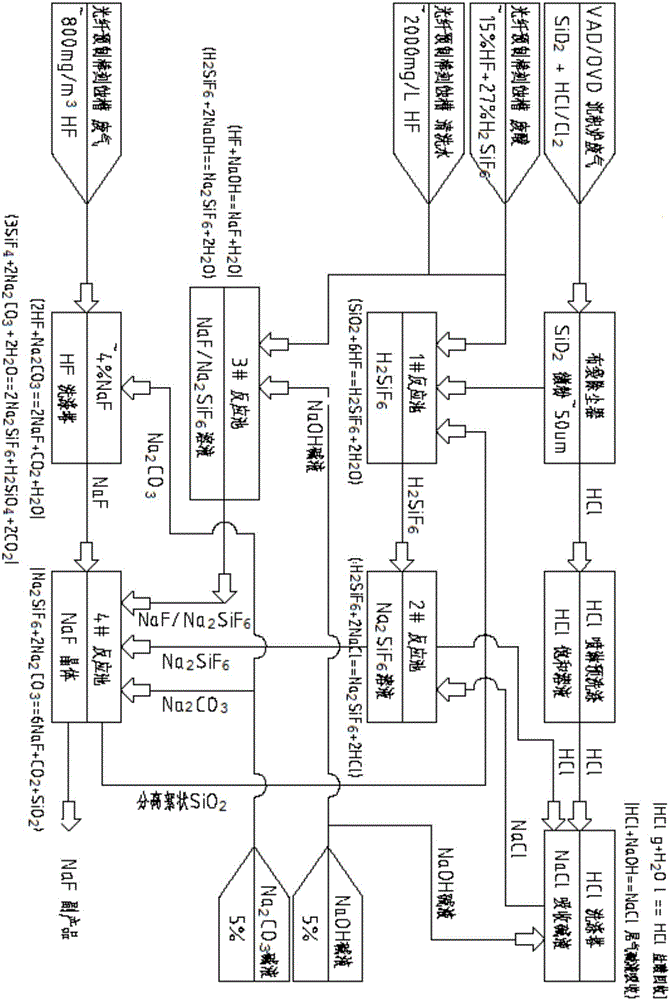

[0048] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0049] like figure 1 Shown, the waste treatment method of the gas-phase method quartz product manufacturing process, including steps

[0050] Part of the HCl gas produced by the gas phase method quartz deposition step is treated by the dust collector to generate hydrochloric acid after being washed with water, and the remaining HCl gas reacts with NaOH to generate NaCl and H 2 0, the generated NaCl is added in the second reaction vessel.

[0051] Set up the first reaction vessel as figure 1 In the 1# reaction tank shown, the exhaust gas produced in the vapor phase quartz deposition step is treated by the dust collector and the SiO 2 into the first reaction vessel; at least a part of the waste liquid produced by the quartz etching process is added into the first reaction vessel, and the silicon dioxide reacts with the HF in the waste liquid produced by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com