Method for recycling high-value-added metals from waste nickel-cobalt-manganese lithium ion batteries

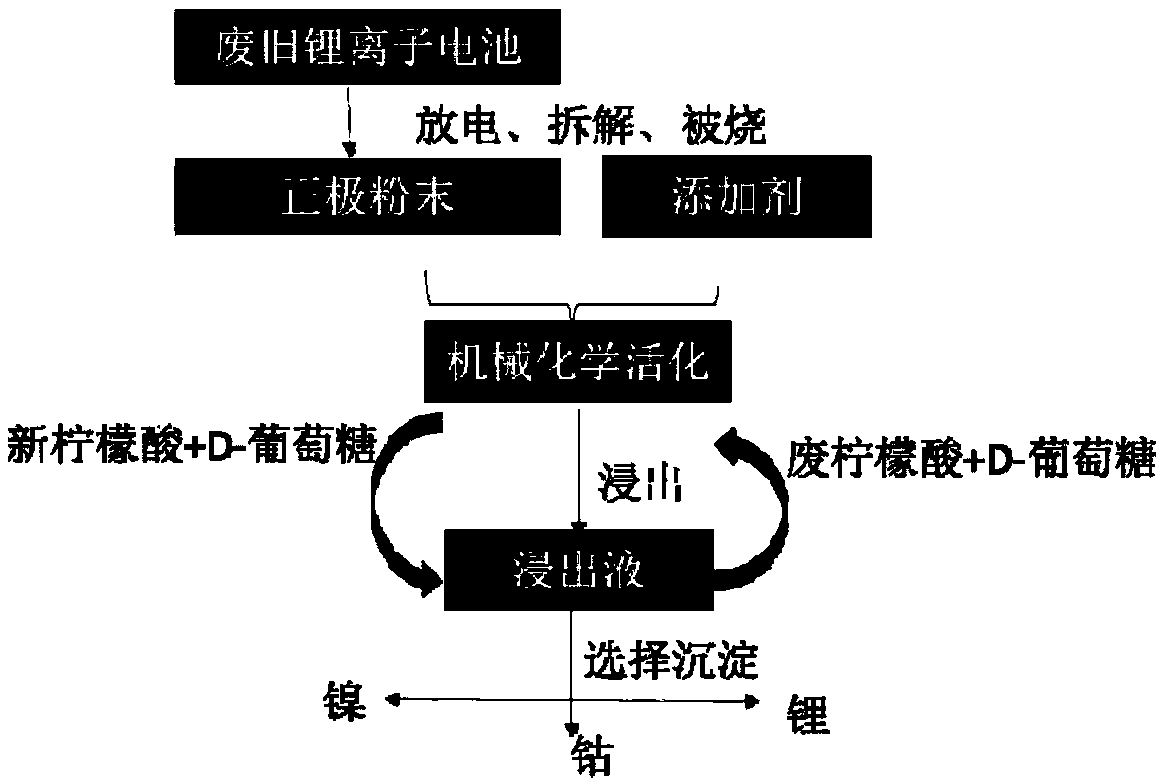

A nickel-cobalt-manganese-lithium and ion battery technology, which is applied in the field of lithium battery recycling, can solve the problems of difficult leachate treatment, environmental secondary pollution, complex process, etc., and achieve the effects of promoting high-efficiency leaching, reducing recycling costs, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

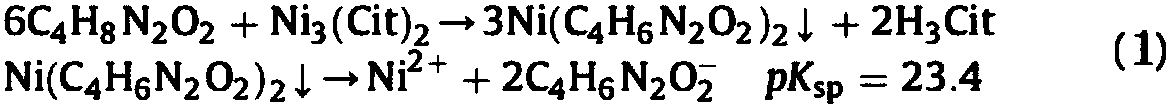

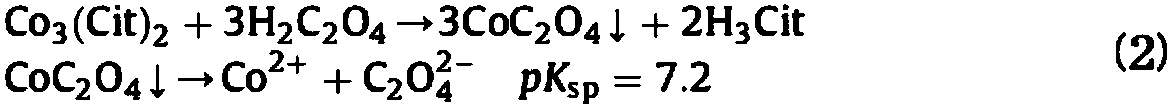

Method used

Image

Examples

Embodiment 1

[0045] A method for recovering high value-added metals from waste nickel-cobalt-manganese lithium-ion batteries, comprising the steps of:

[0046] (1) Put the used battery with voltage into 5% sodium chloride solution with iron powder for thorough discharge, disassemble and select the ternary positive electrode powder containing nickel, cobalt and manganese, and heat treat it in a muffle furnace at 600 °C 0.5h, remove impurities such as binder and conductive agent in the powder;

[0047] (2) Add 6g of heat-treated powder and 1g of EDTA-2Na into a planetary ball mill tank, wherein the mass ratio of balls to materials is 1:1, the ball milling medium is zirconia, the speed is 500rpm, and ball milling is activated for 0.1h;

[0048] (3) Add the activated powder to 0.1M citric acid-D glucose (the mass ratio of citric acid and D glucose is 0.05) leaching solution, wherein the solid-to-liquid ratio is 5g / L, and then react with a condenser The leaching reaction was carried out in the...

Embodiment 2

[0051] A method for recovering high value-added metals from waste nickel-cobalt-manganese lithium-ion batteries, comprising the steps of:

[0052] (1) Put the used battery with voltage into 5% sodium chloride solution with iron powder for thorough discharge, disassemble and select the ternary positive electrode powder containing nickel, cobalt and manganese, and heat treat it in a muffle furnace at 400 °C 2h, remove impurities such as binder and conductive agent in the powder;

[0053] (2) Add 3g of heat-treated powder and 1g of EDTA into a planetary ball mill tank, wherein the mass ratio of ball to material is 1:10, the ball mill medium is zirconia, the speed is 3000rpm, and the ball mill is activated for 5h;

[0054] (3) Add the activated positive electrode powder to 5M citric acid-D glucose (the mass ratio of citric acid and D glucose is 0.5) leaching solution, wherein the solid-to-liquid ratio is 10g / L, and then react with a condenser The leaching reaction was carried out...

Embodiment 3

[0057] A method for recovering high value-added metals from waste nickel-cobalt-manganese lithium-ion batteries, comprising the steps of:

[0058] (1) Put the used battery with voltage into 5% sodium chloride solution with iron powder for thorough discharge, disassemble and select the ternary positive electrode powder containing nickel, cobalt and manganese, and heat treat it in a muffle furnace at 500 °C 1h, remove impurities such as binder and conductive agent in the powder;

[0059] (2) Add 5g of heat-treated powder and 5g of EDTA into a planetary ball mill tank, wherein the mass ratio of balls to materials is 1:20, the ball milling medium is agate beads, the rotation speed is 2000rpm, and the ball milling is activated for 8h;

[0060] (3) Add the activated positive electrode powder to 10M citric acid-D glucose (the mass ratio of citric acid and D glucose is 0.25) leaching solution, wherein the solid-to-liquid ratio is 30g / L, and then react with a condenser The leaching re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com