Method for removing phosphorus in high-phosphorus iron ore by virtue of acid leaching and recycling acid liquor

A high-phosphorus iron ore and acid leaching technology, applied in the direction of improving process efficiency, can solve the problems of harsh production environment, difficult and efficient dephosphorization, acid pollution, etc., to avoid large consumption and environmental pollution, save water resources, The effect of reducing acid consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

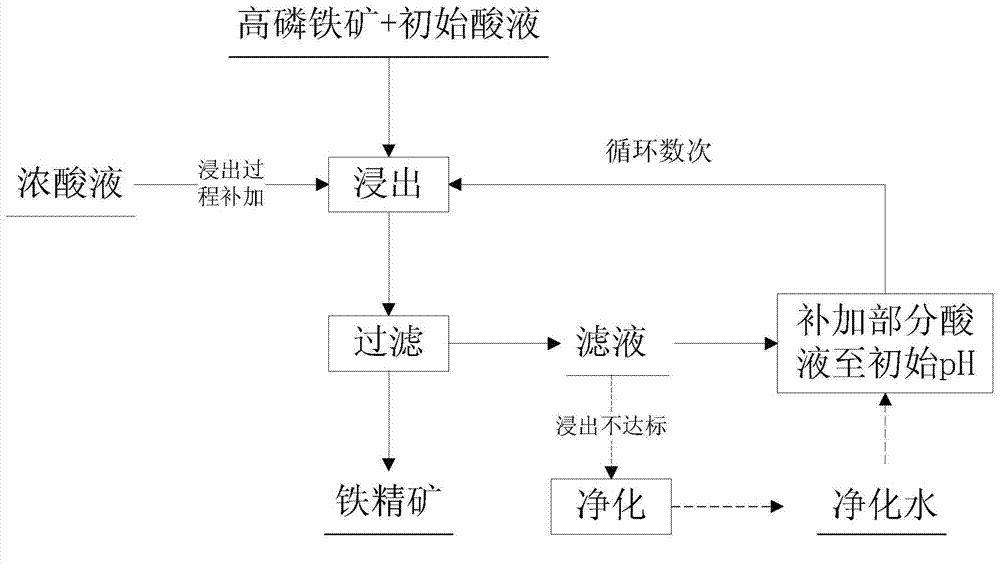

Method used

Image

Examples

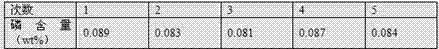

Embodiment 1

[0024] The oolitic high-phosphorite iron ore with an iron grade of 50% and a phosphorus content of 0.7% is crushed and finely ground, and the ore powder with a particle size of 150-200 mesh is screened out, and the hydrochloric acid solution with a volume fraction of 0.75% is mixed evenly in a reaction vessel, and the The leaching dephosphorization operation, wherein the liquid-solid ratio is 1000 ml:100 g, the stirring speed is 400 rpm, the reaction temperature is 25°C, and the reaction time is 1 h. Subsequently, solid-liquid separation was carried out, and the phosphorus content of the obtained filter residue was 0.082%, the iron content was 55%, and the pH of the filtrate was 1.45. When the acid solution was supplemented with part of concentrated hydrochloric acid until the pH was about 1, the new ore was leached, and the other operating conditions were the same as above, and the cycle was repeated 5 times. The phosphorus content of the obtained filter residue was shown in T...

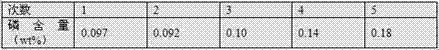

Embodiment 2

[0029] The oolitic high-phosphorite iron ore with an iron grade of 50% and a phosphorus content of 0.7% is crushed and finely ground, and the ore powder with a particle size of 150-200 mesh is sieved, mixed with a hydrochloric acid solution with a volume fraction of 2% in a reaction vessel, and carried out The leaching dephosphorization operation, wherein the liquid-solid ratio is 1000 ml:300 g, the stirring speed is 400 rpm, the reaction temperature is 25°C, and the reaction time is 1 h. Due to the small liquid-solid ratio, when the pH is greater than 1.5 during the reaction, some concentrated hydrochloric acid is added to keep the pH value below 1.5. After the reaction, the solid-liquid separation is carried out. The phosphorus content in the filter residue is 0.091%, and the iron content is 0.091%. It was 56%, and the pH of the filtrate was 1.1. Add part of concentrated hydrochloric acid to the waste acid solution until the pH is about 0.7, and then leaching the new ore. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com