Slurry state synthetic method for porous composite framework material

A framework material and synthesis method technology, applied in chemical instruments and methods, preparation of organic compounds, copper-organic compounds, etc., can solve the problems that the slurry method is not used to synthesize inorganic-organic composite framework materials, and the solvent is in a blank stage. Achieve the effect of eliminating the discharge of metal ions and organic ligands, facilitating adsorption and storage, and avoiding washing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: A method for synthesizing a porous composite framework material in a slurry state, comprising the following steps: (1) selecting a solvent: the solvent is a mixture of 1.6 ml of deionized water and 1.4 ml of ethanol;

[0023] (2) Accurately weigh 0.0061 moles of copper nitrate trihydrate as the metal precursor, and accurately weigh 0.004 moles of trimesic acid as the organic ligand of the porous composite framework material;

[0024] (3) At room temperature, add copper nitrate trihydrate to the solvent prepared in step (1), stir for 10 minutes, then add trimesic acid, stir for 2 hours to form a slurry, seal it in a self-pressurized reactor, and heat to 110 °C for 10 h, and dried at room temperature to obtain a granular product.

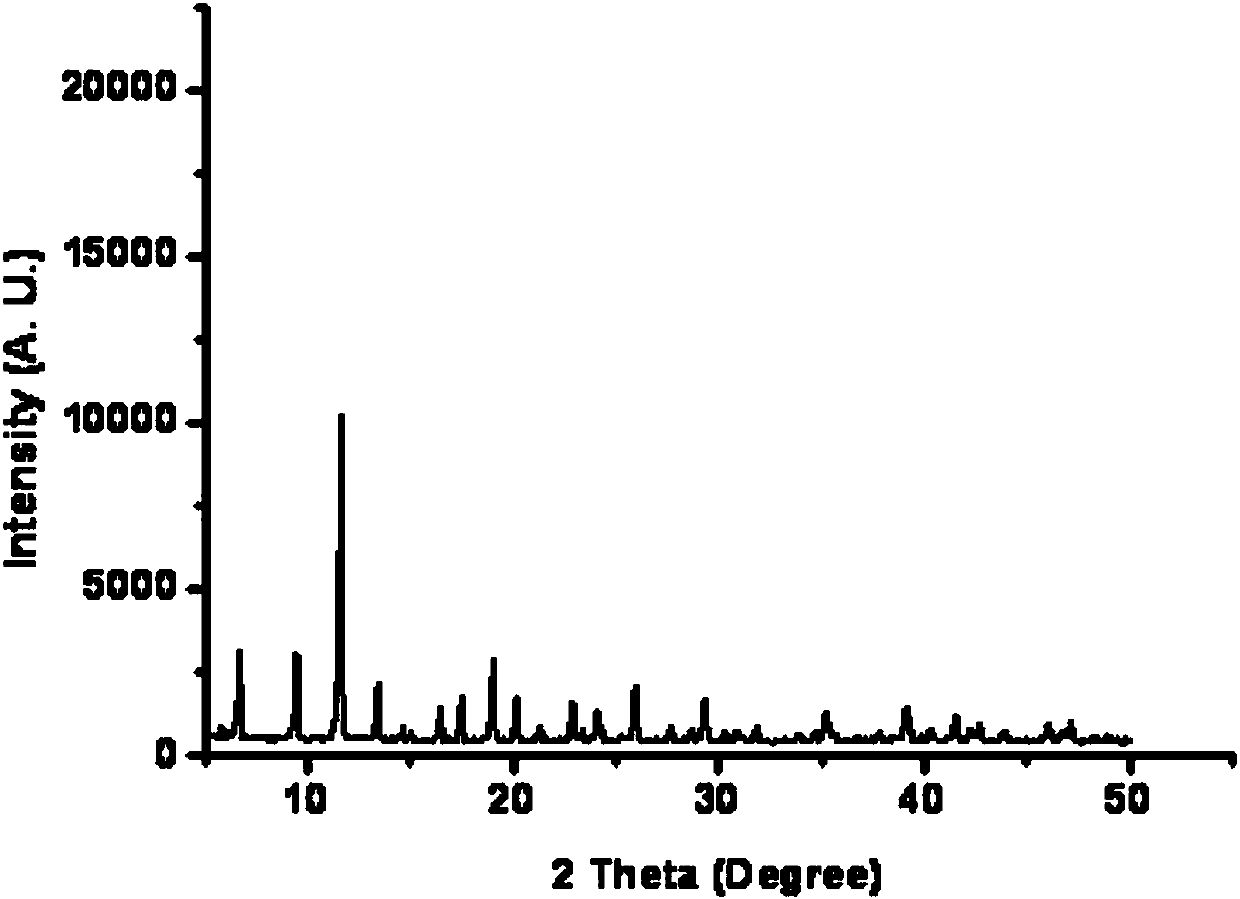

[0025] The granular product that obtains is photographed, and optical photo shows that the size of most of particles is about about 140 microns (as Image 6 shown), the XRD pattern shows that its crystallinity is high, and the growt...

Embodiment 2

[0026] Embodiment 2: A method for synthesizing a porous composite skeleton material in a slurry state, comprising the following steps: (1) selecting a solvent: the solvent is a mixture of 1.0 ml of deionized water and 2.0 ml of industrial alcohol;

[0027] (2) Accurately weigh 0.0061 mole of copper sulfate as the metal precursor, and accurately weigh 0.004 mole of trimesic acid as the organic ligand of the porous composite framework material;

[0028] (3) At room temperature, add copper sulfate to the solvent prepared in step (1), stir for 10 minutes, then add trimesic acid, stir for 2 hours to form a slurry, seal it in a self-pressurized reactor, and heat it to 100°C for reaction After 16 hours, dry at room temperature to obtain a granular product.

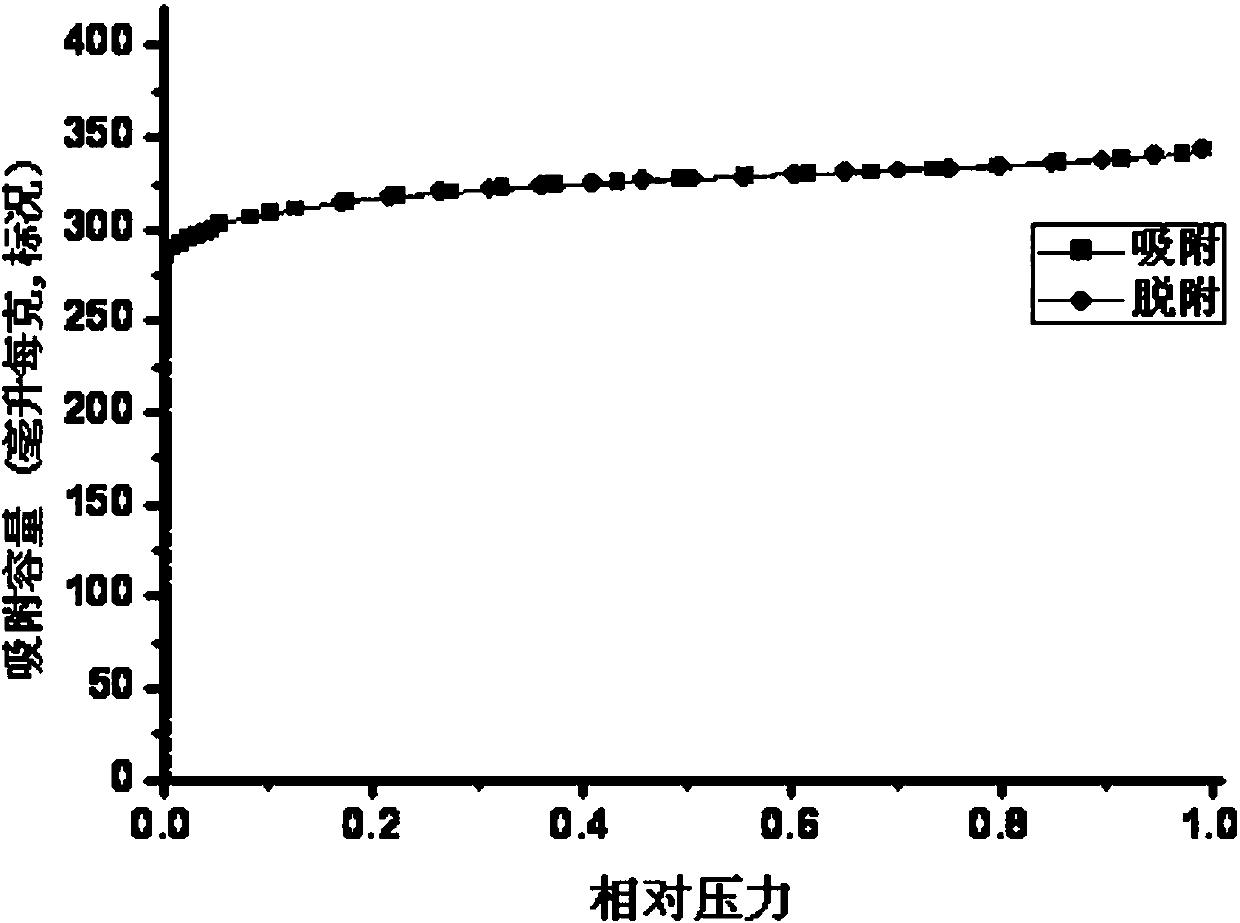

[0029]The test of the product shows that the optical photos show that its size is about 130 microns, the specific surface area is about 1690 square meters per gram, the pore volume is about 0.53 cubic centimeters per gram, the po...

Embodiment 3

[0030] Embodiment 3: A method for synthesizing a porous composite skeleton material in a slurry state, comprising the following steps: (1) selecting a solvent: the solvent is mixed with 1.2 ml of deionized water and 1.8 ml of ethylene glycol;

[0031] (2) Accurately weigh 0.0061 mole of copper chloride as the metal precursor, and accurately weigh 0.004 mole of trimesic acid as the organic ligand of the porous composite framework material;

[0032] (3) At room temperature, add copper chloride to the solvent prepared in step (1), stir for 10 minutes, then add trimesic acid, stir for 2 hours to form a slurry, seal it in a self-pressurized reactor, and heat to 110°C After reacting for 13 hours, the granular product can be obtained by drying at room temperature.

[0033] The test of the product shows that the optical photos show that its size is about 110 microns, the specific surface area is about 1601 square meters per gram, the pore volume is about 0.50 cubic centimeters per gra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com