Polishing solution for processing surfaces of copper and copper alloy by replacing copper pickling process

A polishing liquid and copper alloy technology, applied in the field of chemical polishing liquid, can solve the problems of unresolved stability of hydrogen peroxide, unstable brightness, difficult sewage treatment, etc., achieve batch and mechanized operations, and solve the quality of copper pickling. Instability, the effect of solving the stability problem of hydrogen peroxide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

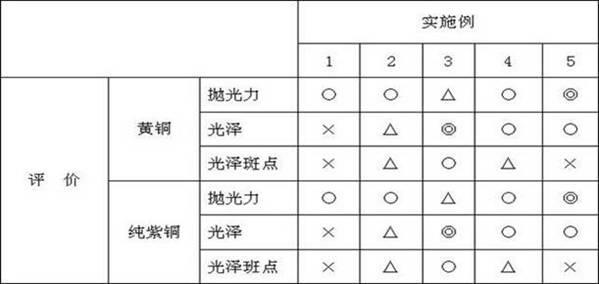

Examples

Embodiment 1

[0037] Embodiment 1. The chemical polishing solution is prepared by 10% hydrogen peroxide (hydrogen peroxide), 7% methanol, 0.8% concentrated sulfuric acid, OP-105% and about 78% purified water.

Embodiment 2

[0038] Embodiment 2. The chemical polishing liquid is prepared by 20% hydrogen peroxide (hydrogen peroxide), 6% ethanol, 1.0% concentrated sulfuric acid plus 4% and about 70% pure water.

Embodiment 3

[0039] Embodiment 3. The chemical polishing solution is prepared by 30% hydrogen peroxide (hydrogen peroxide), 5% ethylene glycol, 1.2% concentrated sulfuric acid, 3% polyethylene glycol and about 62% purified water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com