Polishing solution for replacing copper pickling process to teat copper and copper alloy surface

A technology of polishing liquid and copper alloy, which is applied in the field of metal surface treatment chemical polishing, can solve the problems of unstable brightness, over-corrosion, damage, etc., and achieve the solution of unstable copper pickling quality and the generation of nitrogen oxides The effect of labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

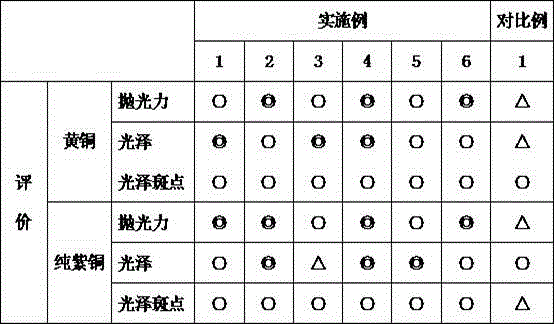

Examples

Embodiment 1

[0015] A polishing solution for treating copper and copper alloy surfaces that replaces the copper pickling process. In terms of mass percentage, the polishing solution is composed of the following components: 5% potassium persulfate, 1% phytic acid, 1% potassium iodate, The molecular weight is 2000 polyacrylamide 0.01%, oleic acid triethanolamine 0.5%, tetramethylammonium hydroxide 3%, surfactant coconut oil fatty acid diethanolamide 0.1%, complexing agent 0.1%, nonylphenol polyoxyethylene Ether 0.5%, the balance is deionized water; the complexing agent is composed of tetrasodium hydroxyethylidene diphosphonate and commercially available FA / O complexing agent in a weight ratio of 1:1.

Embodiment 2

[0017] A polishing solution for treating copper and copper alloy surfaces that replaces the copper pickling process. In terms of mass percentage, the polishing solution is composed of the following components: 10% ammonium persulfate, 5% phytic acid, 3% potassium iodate, Molecular weight is 10000 polyacrylamide 2%, oleic acid triethanolamine 2%, tetramethylammonium hydroxide 10%, surfactant coconut oil fatty acid diethanolamide 1%, complexing agent 3%, brightener flat plus 1%, The balance is deionized water; the complexing agent is composed of tetrasodium hydroxyethylidene diphosphonate and commercially available FA / O complexing agent in a weight ratio of 1:2.

Embodiment 3

[0019] A polishing solution for treating copper and copper alloy surfaces that replaces the copper pickling process. In terms of mass percentage, the polishing solution is composed of the following components: 8% sodium persulfate, 3% phytic acid, 2% potassium iodate, The molecular weight is 5000 polyacrylamide 0.08%, oleic acid triethanolamine 1%, tetramethylammonium hydroxide 6%, surfactant coconut oil fatty acid diethanolamide 0.5%, complexing agent 1.5%, brightener aminoazole 0.7%, The balance is deionized water; the complexing agent is composed of tetrasodium hydroxyethylidene diphosphonate and commercially available FA / O complexing agent in a weight ratio of 1:1.2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com