Method for separating and purifying luteolin

A luteolin and purpose technology, which is applied in the field of separation and purification of active ingredients of natural products, can solve the problems of large consumption of mobile phase, large amount of solvents, high operating costs, etc., achieve high strength and stability, avoid large consumption, and reduce separation costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

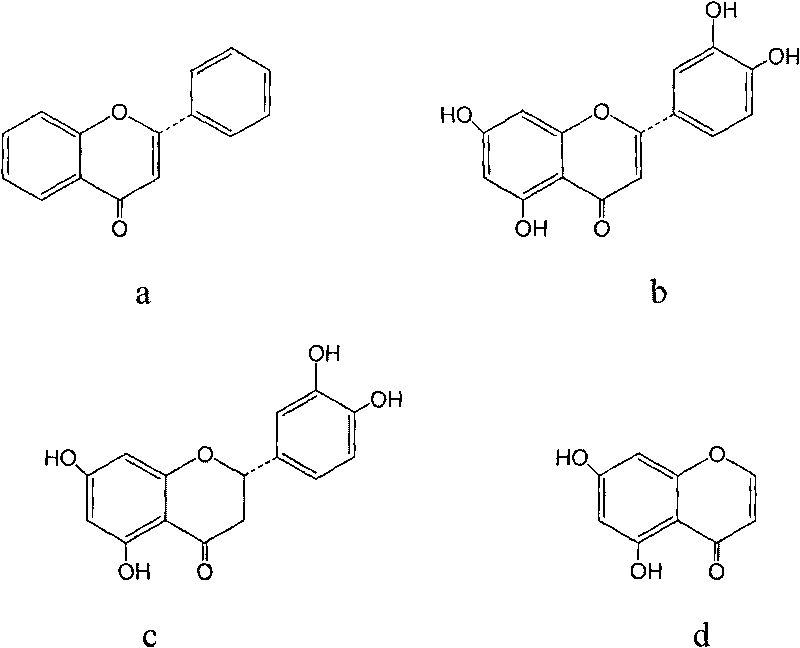

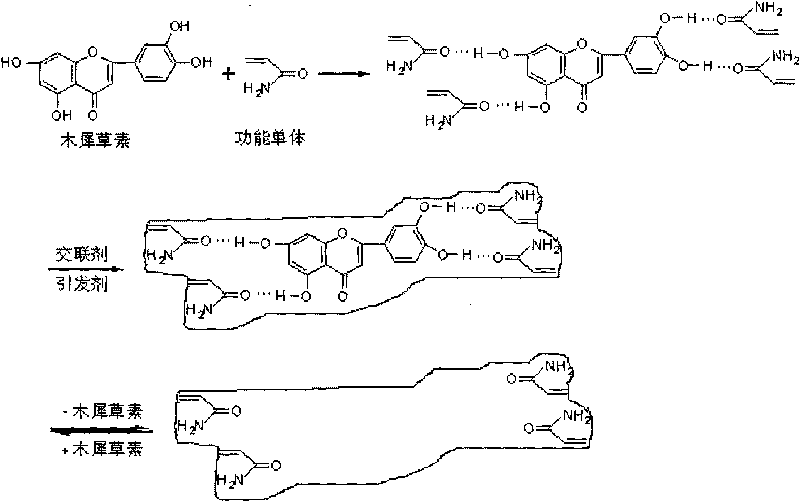

Method used

Image

Examples

example 1

[0032] 1. Preparation of luteolin molecularly imprinted polymer

[0033] Weigh 0.731g luteolin, 0.706g acrylamide, 10g pentaerythritol triacrylate (PETRA) and 0.03g azobisisoheptanonitrile and dissolve them in 20ml acetone, sonicate in a beaker, then pour the solution into a sealable container (test tube), seal it, pass Ar 2 For deoxidation, put the sealed container into a constant temperature water bath at 60°C for polymerization. The preparation of blank polymers (NMIPs) was the same except that the template molecule luteolin was not added. After the polymerization is completed, the bulk polymer in the container is smashed into small pieces and ground to obtain granular polymer. A solution of methanol: acetic acid (9: 1) was used to elute to remove solvents, initiators and template molecules that did not participate in the polymerization to obtain a molecularly imprinted polymer of luteolin.

[0034] 2. Separation and purification of luteolin concentrate

[0035] Weigh 3...

example 2

[0037] 1. Preparation of luteolin molecularly imprinted polymer

[0038] Weigh 0.713g luteolin, 0.883g 2,6-diacrylamide pyridine, 10g EDMA and 0.03g AIBN and dissolve in 20ml acetone, ultrasonically in a beaker, then pour the solution into a sealable container (round bottom flask) In, to seal, through Ar 2 For deoxidation, put the sealed container into a constant temperature water bath at 60°C for polymerization. The preparation of blank polymers (NMIPs) was the same except that the template molecule luteolin was not added. After the polymerization is completed, the bulk polymer in the container is smashed into small pieces and ground to obtain granular polymer. A solution of methanol: acetic acid (9: 1) was used to elute to remove solvents, initiators and template molecules that did not participate in the polymerization to obtain a molecularly imprinted polymer of luteolin.

[0039] 2. Separation and purification of luteolin concentrate

[0040] Weigh 2 g of the eluted lu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com