Pure pine beaverboard preparation

A technology of pine fiber and production method, applied in chemical instruments and methods, wood processing appliances, solid separation, etc., can solve the problems of dark wood fiberboard, affecting product quality, water spots on products, etc., and achieving strength and waterproof performance. Improve, improve appearance quality, good effect of fiber shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

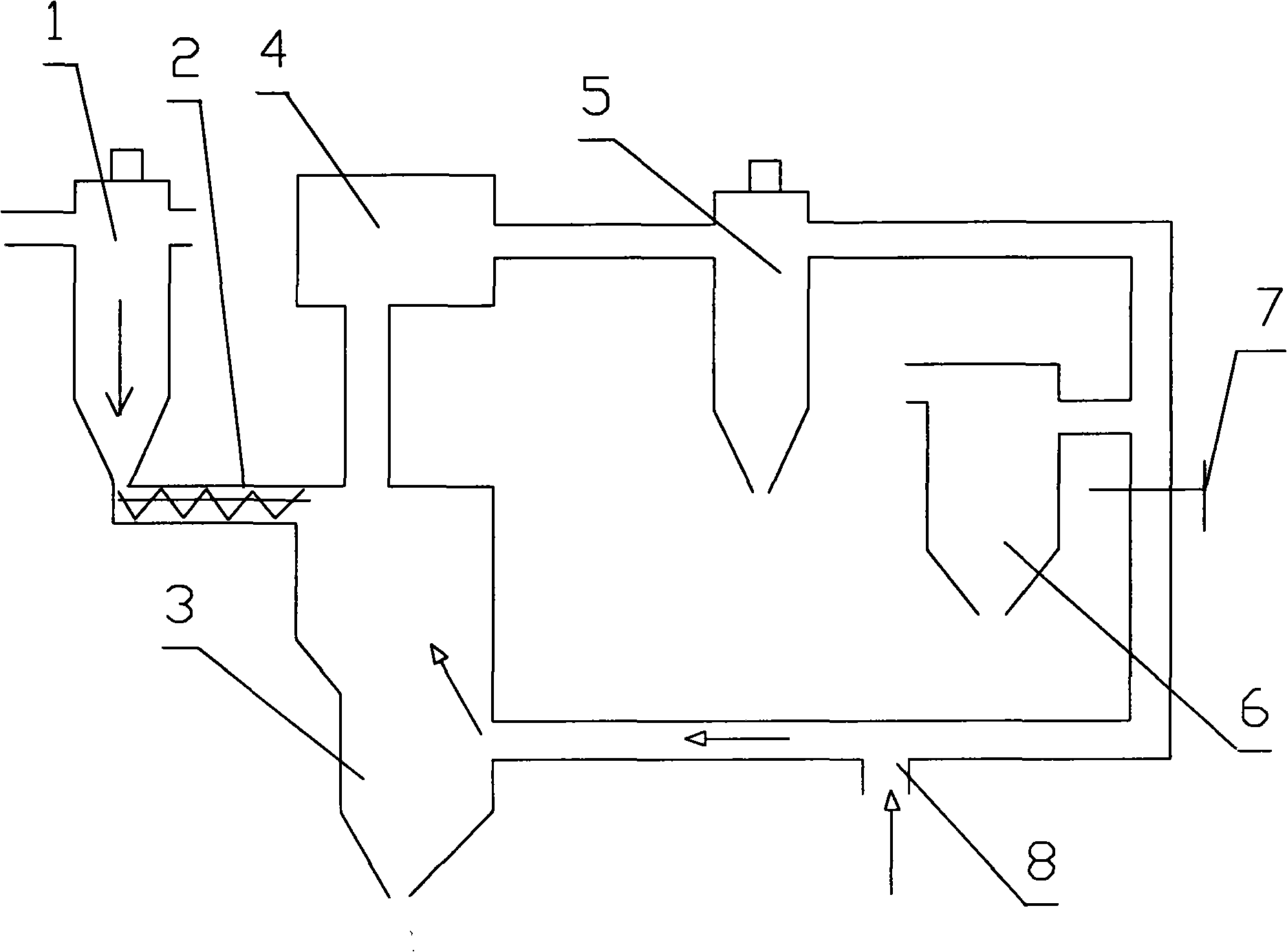

Image

Examples

Embodiment Construction

[0021] A. Pre-cooking: Peel the debarked pine wood into pieces by a peeling machine, and then put it into the cooking bin for pre-cooking at a temperature of 60-80°C; the time is about half an hour.

[0022] B. Cooking: Pressure cook the pre-cooked pine chips, the cooking pressure is 7.3bar, the temperature is 160-170°C, and the time is 3-4 minutes;

[0023] C. Thermal grinding: put the steamed pine chips into the thermal grinding machine and grind them into wood fibers;

[0024] D, drying: the wood fiber is dried to a moisture content of 9-11% through a drying pipe;

[0025] E. Rotating glue, paraffin wax and white pulp: Spray glue, paraffin wax and white pulp to the wood fiber in the drying pipe through a spray machine, and the amount of spraying per cubic meter of board: glue 190kg, paraffin wax 7kg, white pulp 4kg; white pulp is for processing A white paste commonly used in paints and coatings. "Paint white paste 7802" produced by "Tianjin Dyeing and Chemical No. become...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com