Method for efficiently separating and purifying caspofungin

A separation and purification, caspofungin technology, applied in the field of high-efficiency separation and purification of caspofungin, can solve the problems of low product purity, low process efficiency, low sample loading, etc., and achieves good repeatability and solvent consumption. Fewer, faster separation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

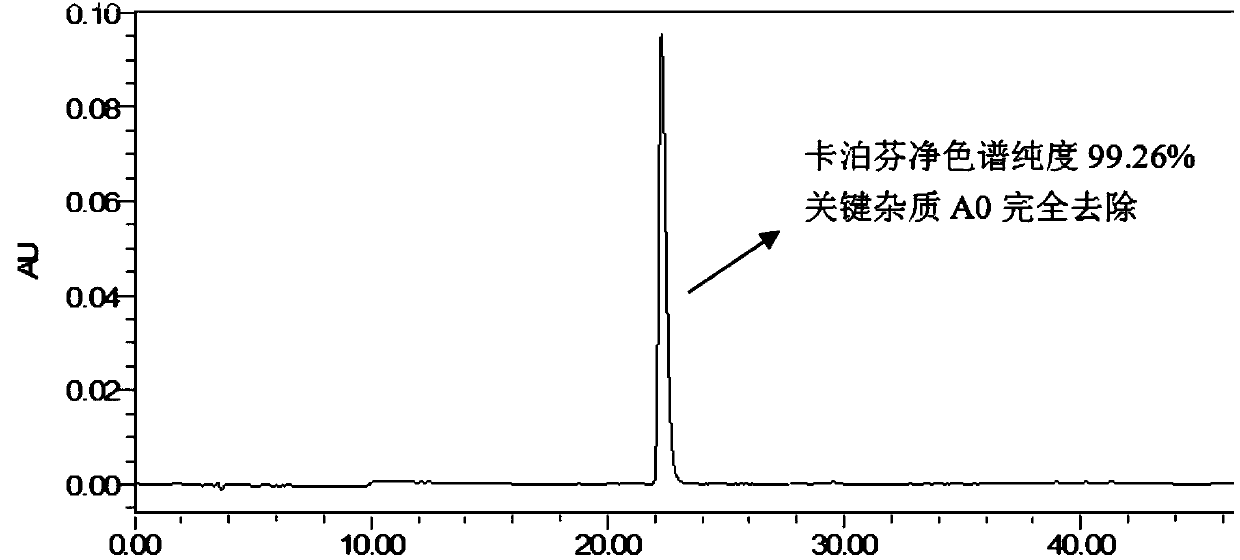

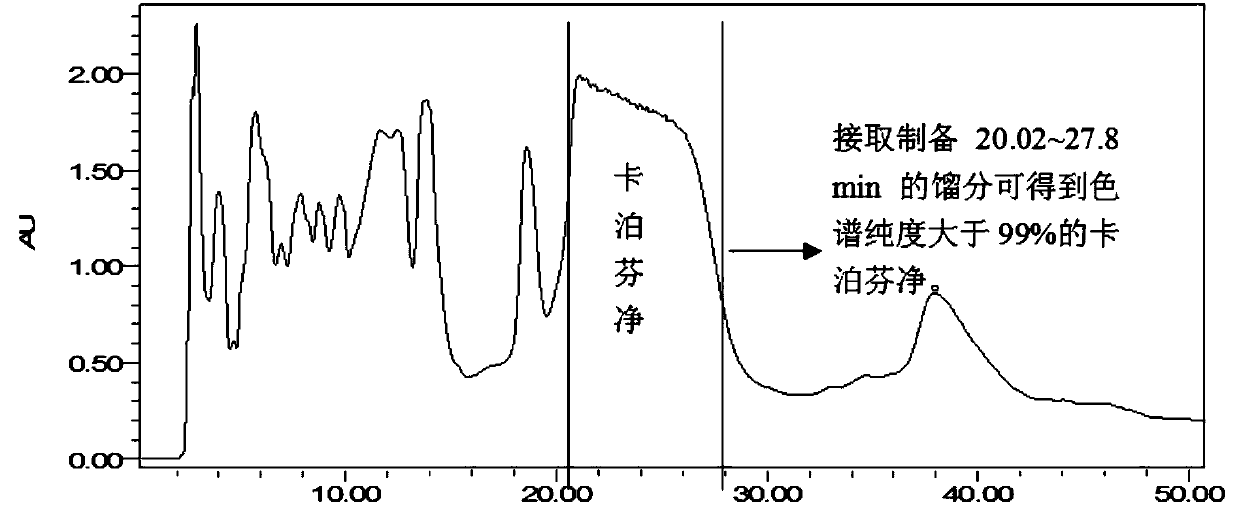

[0027] Caspofungin crude product 1g is dissolved in 10mL ethanol-ammonium perchlorate solution, the injection volume is 10mL, and the loading volume is 0.33%; a hydrophilic silica gel column (column specification 50×250mm, particle diameter 10 μm) bonded with a carboxyl group is used , aperture Packing quality 300g), flow rate 100mL / min; Immediately after loading the sample, use 77% (V / V) ethanol-10mM ammonium perchlorate solution for isocratic elution; UV detector, detection wavelength 220nm, starting from the target peak The fraction is connected until the peak returns to the baseline and stops. After desalination, a product with a purity of caspofungin of more than 99.1% and an impurity A0 of less than 0.1% can be obtained.

Embodiment 2

[0029] Other conditions are identical with embodiment 1, and difference is that filler aperture is After purification and desalination, a product with a purity of more than 99.5% of caspofungin and an impurity A0 of less than 0.1% can be obtained.

Embodiment 3

[0031] Other conditions are identical with embodiment 1, and difference is to use carboxyl hydrophilic silica gel column (column specification 50 * 1000mm, particle diameter 30 μ m, pore diameter Filler quality 1.2kg), desalting after purification can obtain the product that caspofungin purity is more than 99.5%, and impurity A0 is less than 0.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com