Device for producing high-purity boron trichloride and production method of device

A high-purity boron trichloride and three-way technology, which is applied in chemical instruments and methods, separation methods, boron halide compounds, etc., can solve the problems of complicated process, high price and high cost of boron trifluoride, and achieve low price , low production cost and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

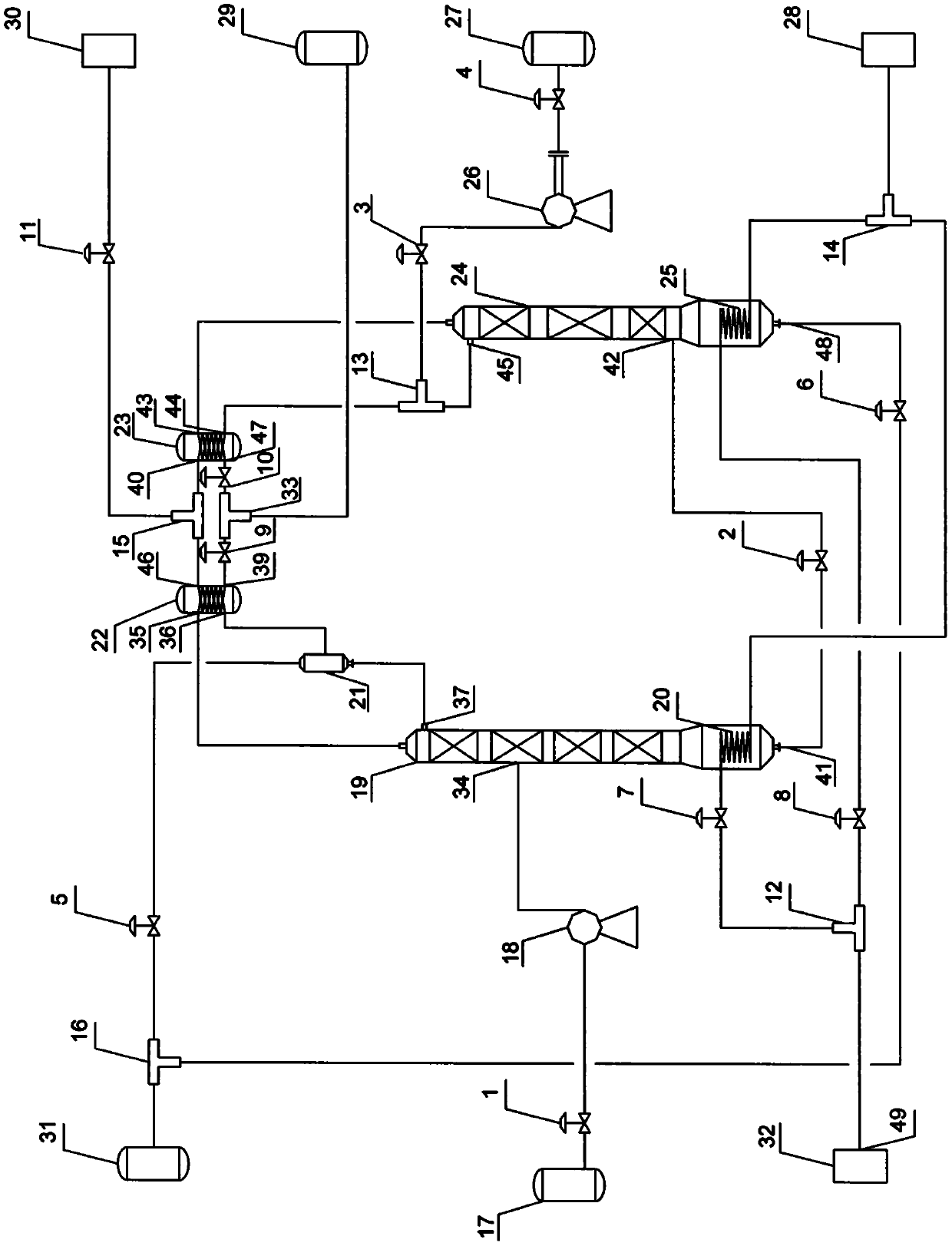

[0041] A device for producing high-purity boron trichloride, comprising a raw material liquid buffer tank 17, a product tank 27, a liquid ammonia storage tank 29 and a circulating water return pool 32, and the raw material liquid buffer tank 17 is connected to the first The first feed liquid inlet 34 in the upper part of the rectification tower 19 links to each other, the liquid phase outlet 41 at the bottom of the first rectification tower 19 links to each other with the first feed liquid inlet 42 of the second rectification tower 24, the second rectification tower 24 The top gas phase outlet is connected to the product tank 27 through the first tube side inlet 43 of the second heat exchanger 23 , the first tube side outlet 44 of the second heat exchanger 23 , the first tee 13 and the product pump 26 in sequence. The gas phase outlet at the top of the first rectifying tower 19 passes through the first tube side inlet 35 of the first heat exchanger 22, the first tube side outle...

Embodiment 2

[0052] A device for producing high-purity boron trichloride, comprising a raw material liquid buffer tank 17, a product tank 27, a liquid ammonia storage tank 29 and a circulating water return pool 32, and the raw material liquid buffer tank 17 is connected to the first The first feed liquid inlet 34 in the upper part of the rectification tower 19 links to each other, the liquid phase outlet 41 at the bottom of the first rectification tower 19 links to each other with the first feed liquid inlet 42 of the second rectification tower 24, the second rectification tower 24 The top gas phase outlet is connected to the product tank 27 through the first tube side inlet 43 of the second heat exchanger 23 , the first tube side outlet 44 of the second heat exchanger 23 , the first tee 13 and the product pump 26 in sequence. The gas phase outlet at the top of the first rectifying tower 19 passes through the first tube side inlet 35 of the first heat exchanger 22, the first tube side outle...

Embodiment 3

[0063]A device for producing high-purity boron trichloride, comprising a raw material liquid buffer tank 17, a product tank 27, a liquid ammonia storage tank 29 and a circulating water return pool 32, and the raw material liquid buffer tank 17 is connected to the first The first feed liquid inlet 34 in the upper part of the rectification tower 19 links to each other, the liquid phase outlet 41 at the bottom of the first rectification tower 19 links to each other with the first feed liquid inlet 42 of the second rectification tower 24, the second rectification tower 24 The top gas phase outlet is connected to the product tank 27 through the first tube side inlet 43 of the second heat exchanger 23 , the first tube side outlet 44 of the second heat exchanger 23 , the first tee 13 and the product pump 26 in sequence. The gas phase outlet at the top of the first rectifying tower 19 passes through the first tube side inlet 35 of the first heat exchanger 22, the first tube side outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com