A pressure swing adsorption method for pressure change linkage control in cycle operation

A pressure swing adsorption and cyclic operation technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve problems such as high failure rate of program control valves, poor adaptability to raw gas fluctuations, and shortened service life of adsorbents. Achieve the effect of not easy to wear, prolong the service life and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

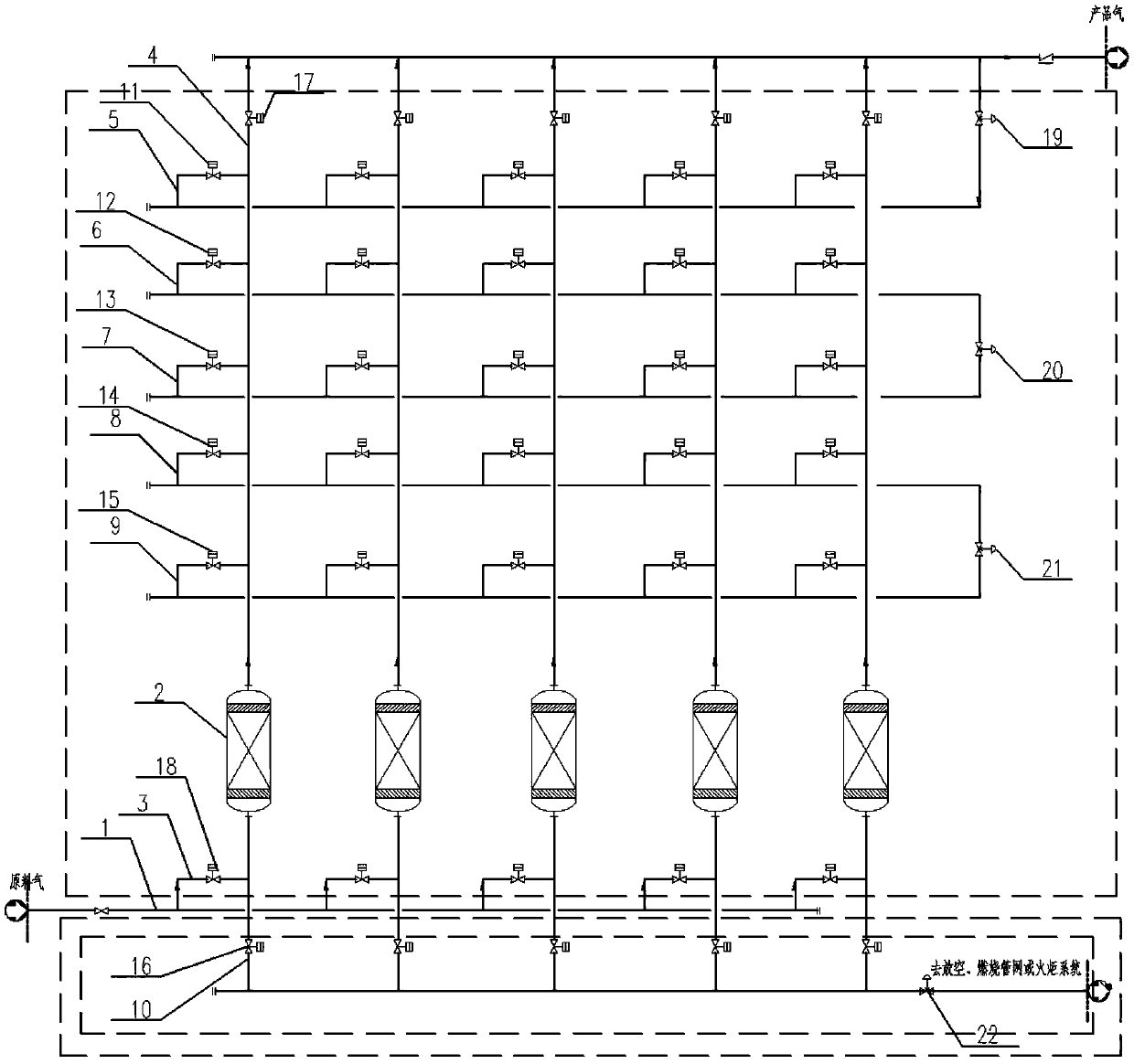

[0044] Such as figure 1 Shown, a kind of pressure swing adsorption method of pressure change linkage control in cyclic operation, described one group (section) pressure swing adsorption (PSA) adsorption and desorption cycle operating system adsorption tower that is formed by 5 adsorption towers is formed The linkage control of the determination mode of the boundary conditions of the inlet and outlet of the adsorption tower (mechanical designation, or independent judgment, or a combination of the two modes) and the program control valve-regulating valve combination in the simulation of the pressure swing adsorption (PSA) adsorption and desorption cycle operation process, According to the real-time pressure in the two target adsorption towers as a reference, by adjusting the opening and closing of the valve combination and the opening degree, the gas flow rate and the pressure change trend in the target adsorption tower and the inlet and outlet are controlled in real time, thus i...

Embodiment 2

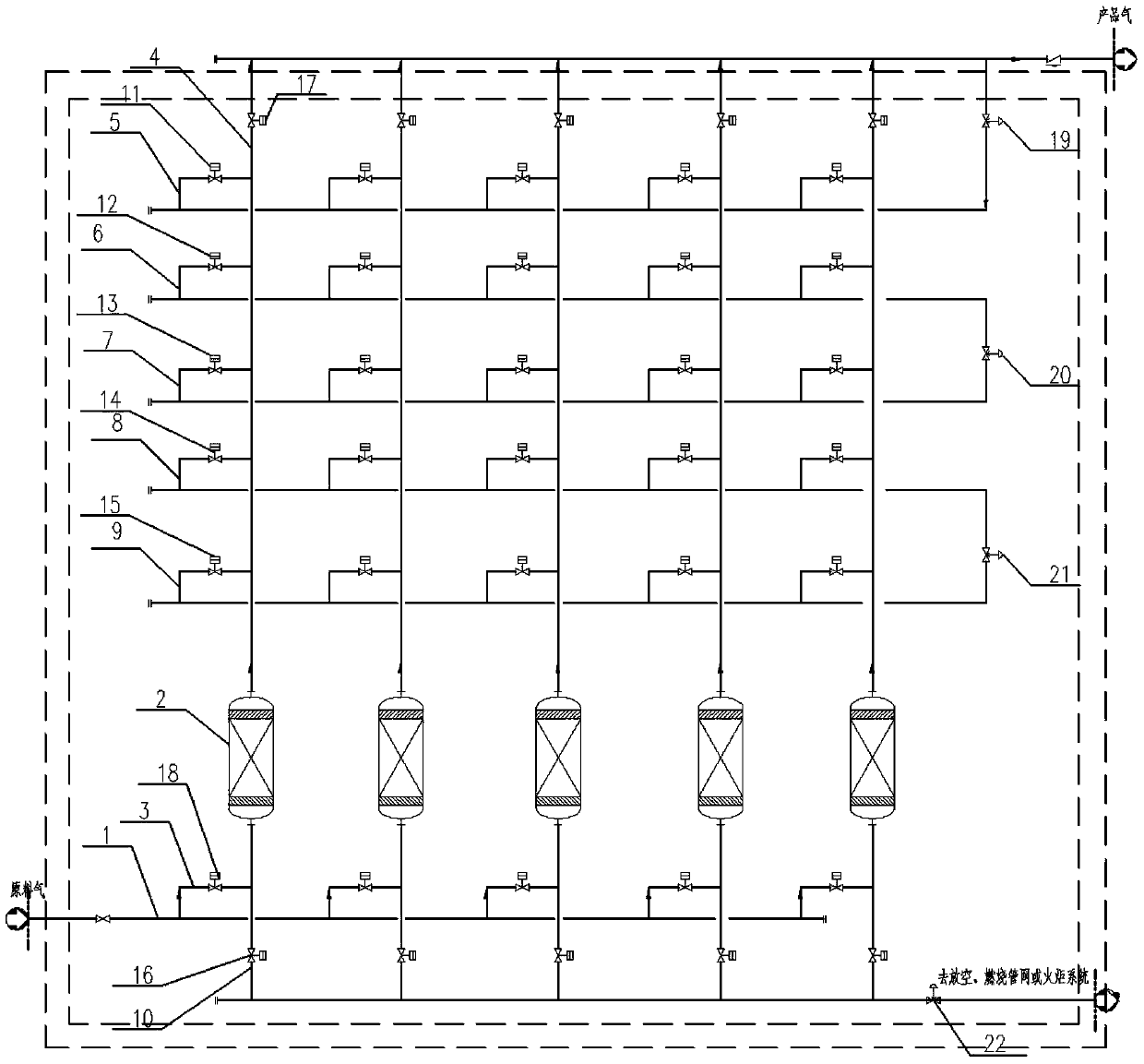

[0057] Such as figure 2 As shown, further optimization on the basis of the pressure swing adsorption method of pressure change linkage control in a cycle operation described in Example 1, the pressure is 2.4MPa, and the temperature is a hydrogen-containing (50-60% H2 ) The feed gas fluctuates, that is, under the same temperature and other conditions, the feed gas pressure fluctuates by more than 5% and rises to 2.6MPa. The pressure swing adsorption (PSA) adsorption and desorption cycle composed of five adsorption towers 2 In the operating system, the operating pressure change of each step is determined by the boundary conditions independently determined by the inlet and outlet of each adsorption tower (indicated by double dashed lines) and the program control valve on the pipeline connected to the inlet and outlet of each adsorption tower- The combination mode of the regulating valve is realized by linkage control, in which the intermediate pressure values of the first-stag...

Embodiment 3

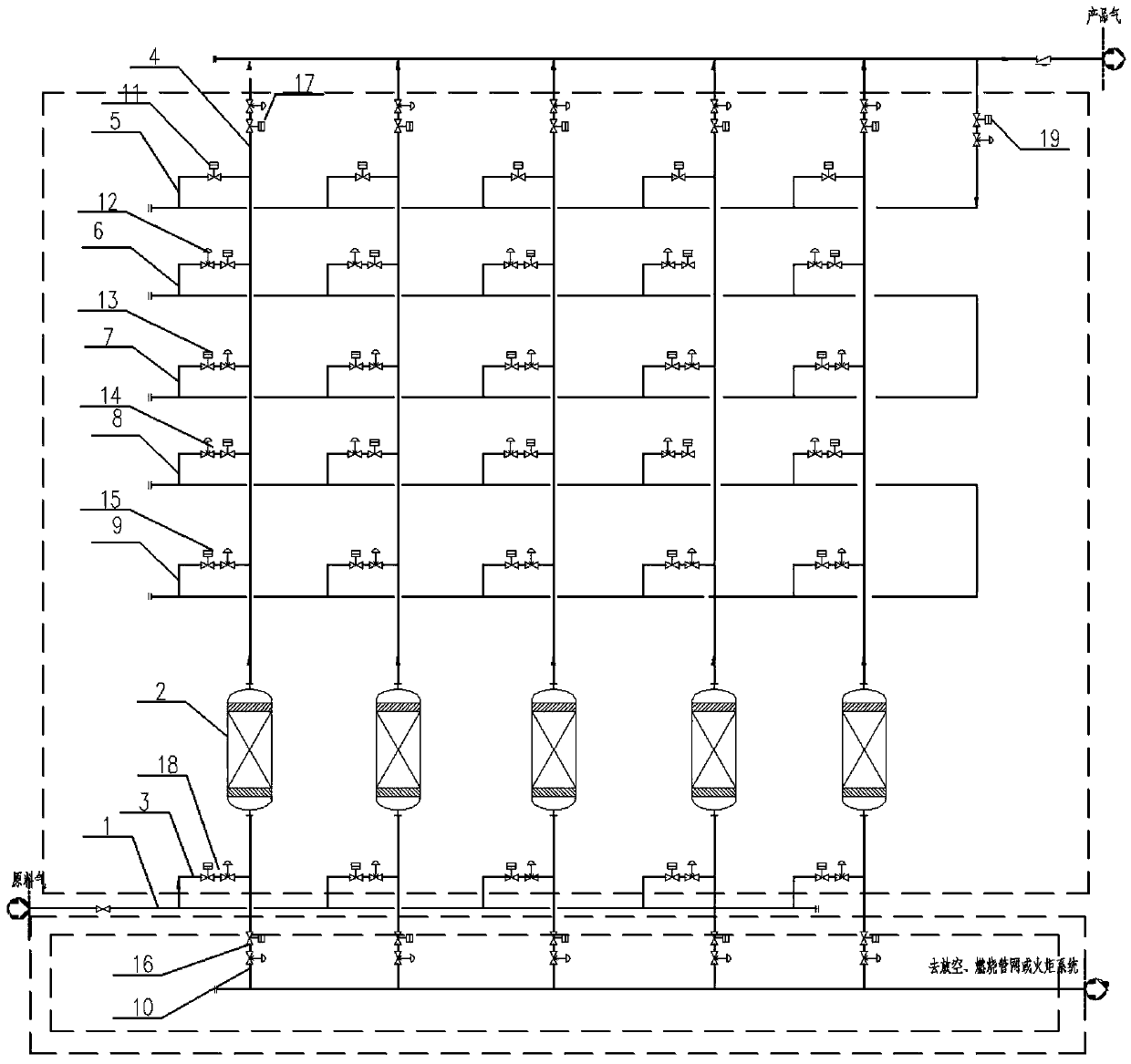

[0059] Such as image 3 As shown, further optimize on the basis of the pressure swing adsorption method of pressure change linkage control in a kind of cyclic operation described in embodiment 1, described pressure swing adsorption (PSA) adsorption that is made up of 5 adsorption towers 2 and In the desorption cycle operating system, the program control valve-regulating valve combination on the pipeline connected to the inlet and outlet of each adsorption tower 2 is a program control valve followed by a regulating valve connected in series to form a one-to-one correspondence combination mode. The purpose of this embodiment is to greatly increase the stability of the system (device), and to be more adaptable to the relatively large fluctuations in pressure during feed gas and cycle operation, so that the operation of the device can at least even exceed the level of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com