A kind of electrochemical preparation method of solid electrolyte lithium lanthanum titanium oxide compound

A solid electrolyte, lithium lanthanum titanium oxide technology, applied in the field of lithium ion batteries, can solve the problems of high energy consumption, high cost, low product purity, etc., achieve the effect of cheap raw materials, simple process, and low product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

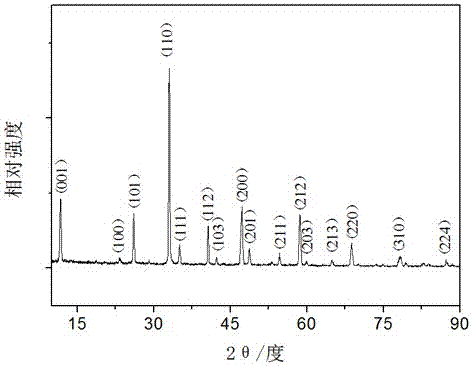

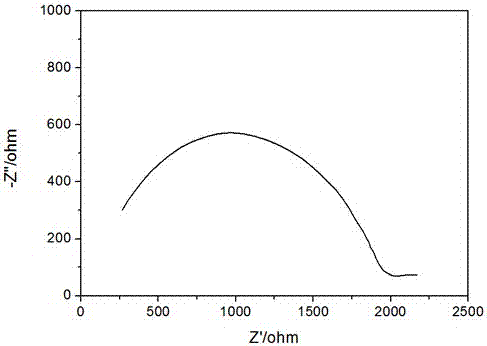

Embodiment 1

[0028] Weigh 0.8g of lanthanum oxide, 0.1g of PVDF and 0.1g of acetylene black, grind them in a mortar for half an hour and mix well, take 0.2g of the mixture and put it into a mold, press it under 20MPa pressure for 1 minute to form a tablet. Use the pressed sheet as the positive electrode, select the CR2032 button battery case, assemble the battery in the order of the negative electrode case, spring sheet, gasket, lithium sheet, diaphragm, positive electrode, and positive electrode case, add 5 drops of lithium-ion battery electrolyte, and seal it with a sealing machine Prepare button cells. Put the prepared button battery on a battery tester, and discharge it at a constant current of 0.05C to a capacity of 15.59mAh. Take out the pressed tablet after lithium intercalation, grind and mix with 0.141g titanium dioxide after drying, pre-fire in a muffle furnace at 800°C for 5 hours, and then sinter at 1000°C for 10 hours after grinding to obtain Li 0.33 La 0.557 TiO 3 , the te...

Embodiment 2

[0030] Weigh 9g of lanthanum oxide, 0.5g of PVDF and 0.5g of Super P, put them into a 100ml ball mill jar with a ball-to-material ratio of 3:1, grind for 2 hours and mix well, take 0.2g of the mixture and put it into a mold, and press it under 20MPa pressure for 1 minute Into pieces. Use the pressed sheet as the positive electrode, select the CR2032 button battery case, assemble the battery in the order of the negative electrode case, spring sheet, gasket, lithium sheet, diaphragm, positive electrode, and positive electrode case, add 5 drops of lithium-ion battery electrolyte, and seal it with a sealing machine Prepare button cells. Put the prepared button battery on the battery tester, and discharge it at a constant current of 0.05C to a capacity of 17.54mAh. Take out the pressed tablet after lithium intercalation, grind and mix with 0.1585g titanium dioxide after drying, pre-fire in a muffle furnace at 550°C for 5 hours, and sinter again at 1200°C for 10 hours after grindin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com