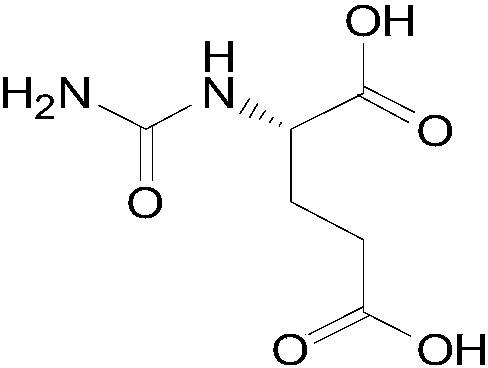

Method for refining carglumic acid

A technology of carboglutamate and carboglutamate, which is applied in chemical instruments and methods, preparation of urea derivatives, preparation of organic compounds, etc., can solve the problem of low purity and achieve the effect of extensive sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

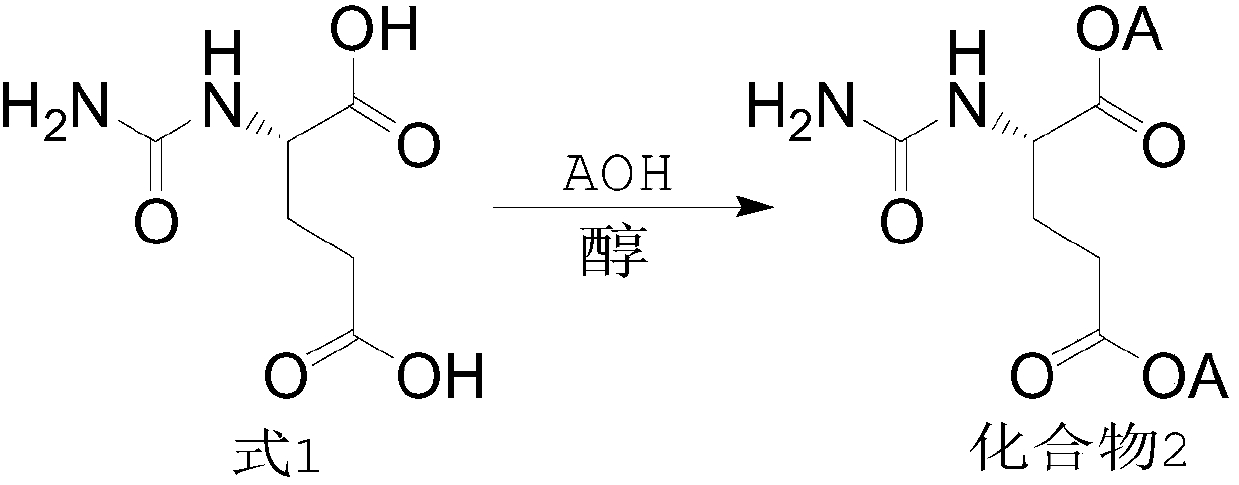

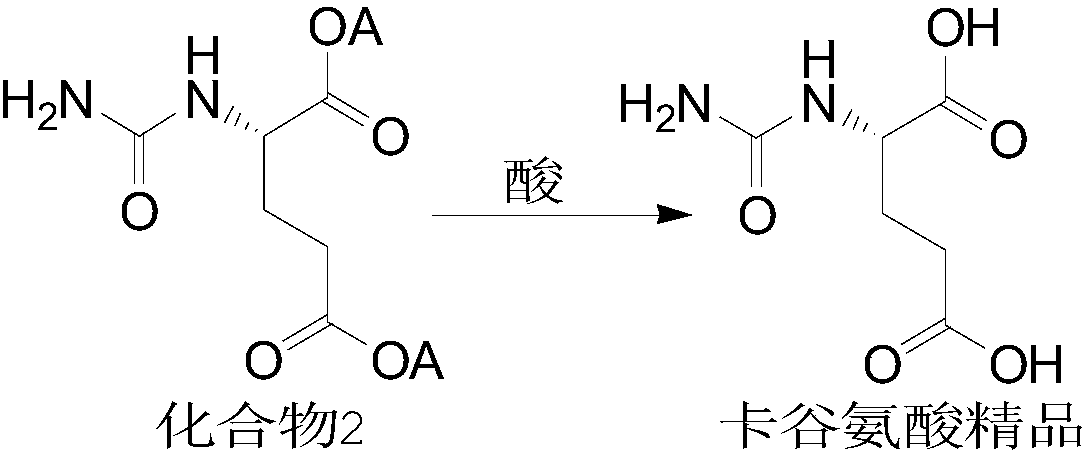

Method used

Image

Examples

Embodiment 1

[0042] 1.47kg of crude carglutamic acid and 5L of ethanol were mixed in a 10L three-neck flask, stirred and heated to 35°C, and a solution prepared by 800g of sodium hydroxide and 3200g of purified water was added thereto. After the addition, stir to clarify the reaction solution. Then keep stirring at 35°C for 0.5h, then cool to 15°C, and crystallize for 10h. Suction filtration to dryness, and drying to obtain 700 g of sodium salt of carboglutamic acid. Mix the above-mentioned ammonium salt with 6L of purified water into a 10L three-neck flask, stir to dissolve, then adjust the pH to 1-2 with acid, cool to 0°C, and crystallize for 10h. After the crystallization is completed, filter to dryness with suction and dry at 30° C. to obtain 370 g of refined glutamic acid, the product has a purity of 99.8%, and the maximum single impurity is less than 0.1%; the product yield is 25.2%.

Embodiment 2

[0044] Mix 4.8kg of crude carboglutamic acid and 20.4L of ethanol in a 50L reactor, stir and raise the temperature to 45°C, and add 13.7kg of concentrated ammonia water dropwise thereto. After the addition, continue to add 1.1kg of purified water, and the reaction solution is clarified. Then keep stirring at 45°C for 0.5h, then cool to 25°C, and crystallize for 20h. Suction filtration to dryness, and drying to obtain 2.3 kg of carboglutamic acid ammonium salt. Mix the above-mentioned ammonium salt with 19L of purified water into a 50L reactor, stir to dissolve, then adjust the pH to 1-2 with acid, cool to 10°C, and crystallize for 20h. After the crystallization is completed, the product is dried by centrifugation and dried at 30° C. to obtain 1.4 kg of refined glutamic acid, with a product content of 99.7 percent and a maximum simple impurity of less than 0.1 percent; the product yield is 29.2 percent.

Embodiment 3

[0046]Mix 4.8 kg of crude carboglutamic acid and 20.4 L of ethanol in a 50 L reactor, stir and heat up to 30° C., and dropwise add 13.7 kg of concentrated ammonia water therein. After the addition, continue to add 1.1kg of purified water, and the reaction solution is clarified. Then keep stirring at 30°C for 1h, then cool to 5°C, and crystallize for 10h. Suction filtration to dryness, and drying to obtain 2.3 kg of carboglutamic acid ammonium salt. Mix the above-mentioned ammonium salt with 19L of purified water into a 50L reactor, stir to dissolve, then adjust the pH to 1-2 with acid, cool to 0°C, and crystallize for 20 hours. After the crystallization is completed, the product is dried by centrifugation and dried at 30° C. to obtain 1.24 kg of refined glutamic acid, the product content is 99.8%, and the maximum simplex is less than 0.1%; the product yield is 25.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com