Recovery method of nylon acid

A technology of nylon acid and glutaric acid, which is applied in the separation/purification of carboxylic acid compounds, organic chemistry, etc., can solve the problem of low purity of glutaric acid, and achieve the effect of improving comprehensive benefits and simple and efficient process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

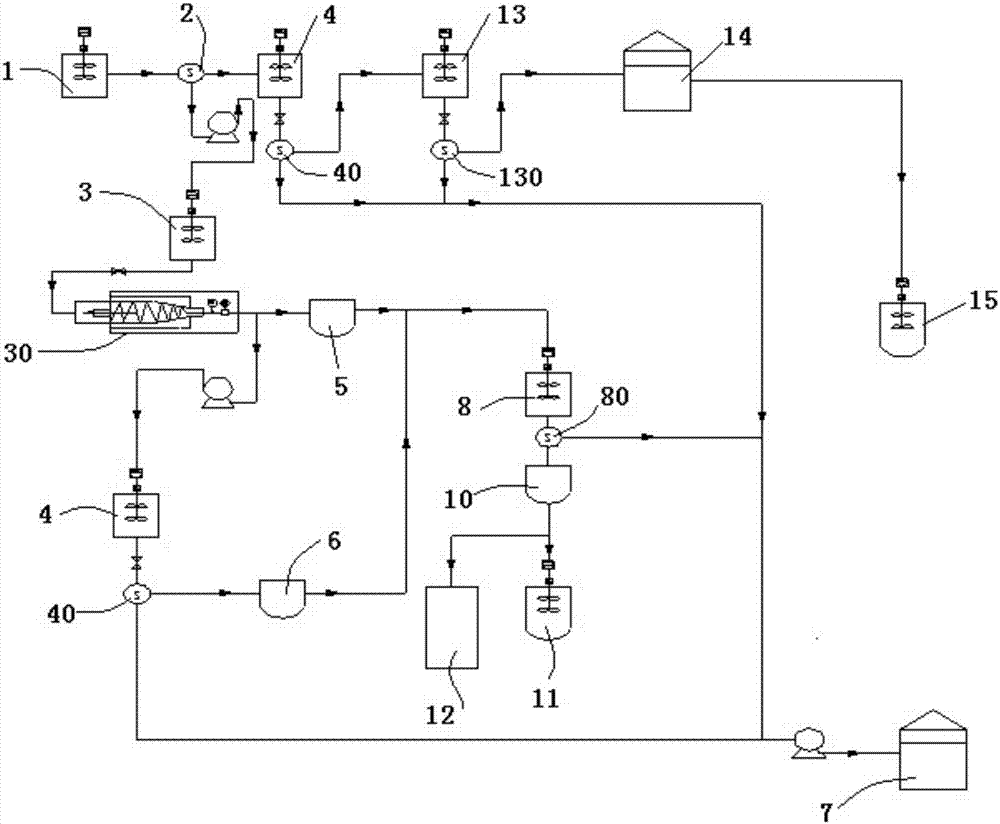

[0035] The recycling method of the nylon acid of the present embodiment, the system that adopts is as figure 1 shown, including the following steps:

[0036] 1) Nylon acid knot sheet (in nylon acid knot sheet, the mass content of succinic acid, glutaric acid, adipic acid is respectively 23%, 65%, 12%) and water are mixed by mass ratio 4:1, in After heating and dissolving at 80°C, cool down to 30°C in the primary crystallizer, stir and crystallize for 7 hours at a stirring rate of 400rpm, and then pump into centrifuge S for centrifugal separation to obtain primary crystals and primary mother liquor;

[0037]2) Remove 15wt% of the water in the primary mother liquor through the tube pass, send it to the first glutaric acid crystallizer, stir and crystallize at 20°C for 4h, the stirring rate is 400rpm, and centrifuge after the crystallization to obtain the crude product Glutaric acid and secondary mother liquor;

[0038] The primary crystal is dissolved in water in the first mix...

Embodiment 2

[0044] The recycling method of the nylon acid of the present embodiment, process flow chart is as figure 1 shown, including the following steps:

[0045] 1) Nylon acid knot sheet (in nylon acid knot sheet, the mass content of succinic acid, glutaric acid, adipic acid is respectively 23%, 65%, 12%) and water are mixed by mass ratio 5:1, in After heating and dissolving at 80°C, cool down to 35°C in the primary crystallizer, stir and crystallize for 5 hours at a stirring rate of 600rpm, and then pump into centrifuge S for centrifugal separation to obtain primary crystals and primary mother liquor;

[0046] 2) Remove 10wt% of the water in the primary mother liquor through the tube pass, send it to the first glutaric acid crystallizer, stir and crystallize at 25°C for 6h, the stirring rate is 600rpm, and perform centrifugation after the crystallization is completed to obtain the crude product Glutaric acid and secondary mother liquor;

[0047] The primary crystal is dissolved in ...

Embodiment 3

[0053] The recycling method of the nylon acid of the present embodiment, process flow chart is as figure 1 shown, including the following steps:

[0054] 1) Nylon acid knot sheet (in nylon acid knot sheet, the mass content of succinic acid, glutaric acid, adipic acid is respectively 23%, 65%, 12%) and water are mixed by mass ratio 1.5:1, in After heating and dissolving at 80°C, cool down to 20°C in the primary crystallizer, stir and crystallize for 4 hours at a stirring rate of 200rpm, and then pump into centrifuge S for centrifugal separation to obtain primary crystals and primary mother liquor;

[0055] 2) Remove 20wt% of the water in the primary mother liquor through the tube pass, send it to the first glutaric acid crystallizer, stir and crystallize at 10°C for 2 hours, the stirring rate is 200rpm, and centrifuge after the crystallization is completed to obtain the crude product Glutaric acid and secondary mother liquor;

[0056] The primary crystal is dissolved in water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com