Organic matter filtrate separating and filtering device

A technology for separating filtration and organic matter, applied in the direction of filtration separation, separation method, filtration loop, etc., can solve the problems of low solution purity, poor separation effect, organic matter volatilization, etc., to achieve good corrosion resistance, strong heat resistance, The effect of improved filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and specific embodiment the invention is further introduced:

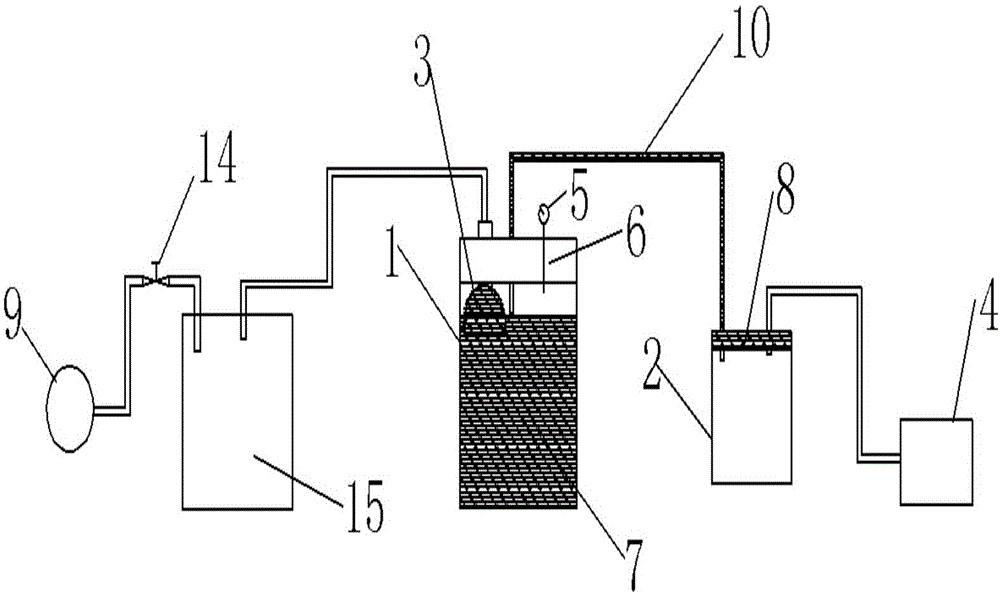

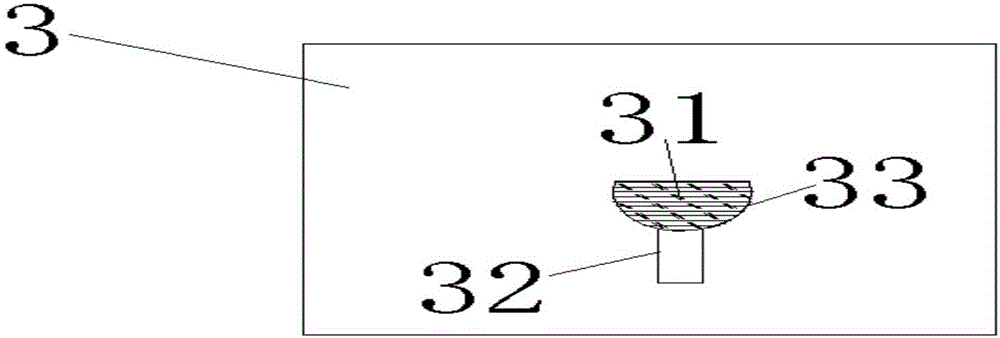

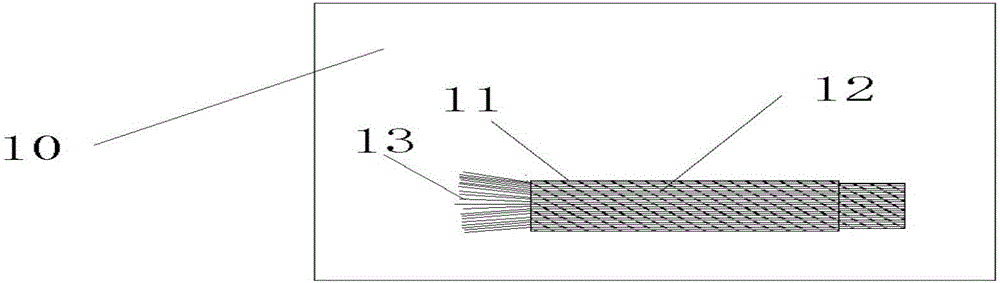

[0031] Such as Figure 1-3 As shown, a kind of organic matter filtrate separation and filtration device comprises large suction filter bottle 1, small suction filter bottle 2, filter plate device 3, nitrogen bag 4, local pressure gauge 5, large suction filter bottle stopper 6, filtrate 7, Small suction filter bottle stopper 8, suction filter pump 9, suction filter tube 10, outer tube 11, internal filler 12, filter element 31, pump connection tube 32, filter plate installation body 33, nitrogen bag 4 through the trachea and small suction filter The bottle 2 is connected; the small suction filter bottle 2 is connected with the large suction filter bottle 1 through the suction filter tube 10; one end of the filter plate device 3 is completely immersed in the filtrate 7 in the large suction filter bottle 1, and the other end passes through the large suction filter b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com