Grain-composition zirconia powder preparation and ceramic sintering method

A technology of zirconia powder and sintering method, applied in the field of ceramic sintering, can solve the problems of insufficient mixing uniformity, reduced production efficiency, easy introduction of impurities, etc., so as to improve the production process, increase the density of the green body, and reduce the shrinkage of sintering. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Weigh 10mmol of zirconium oxychloride, dissolve it in 20ml of deionized water, add yttrium salt according to the molar ratio of yttrium salt and zirconium salt in a ratio of 3:10, and prepare solution A;

[0023] Ammonia and ammonium bicarbonate are used as precipitating agents, and the molar ratio is 6:4, which is prepared into 2mol / l alkaline solution B;

[0024] Slowly add solution A to solution B dropwise, stir at 1000 rpm for 1 hour, then add polyethylene glycol (PEG, 200), and stir for 0.5 hour;

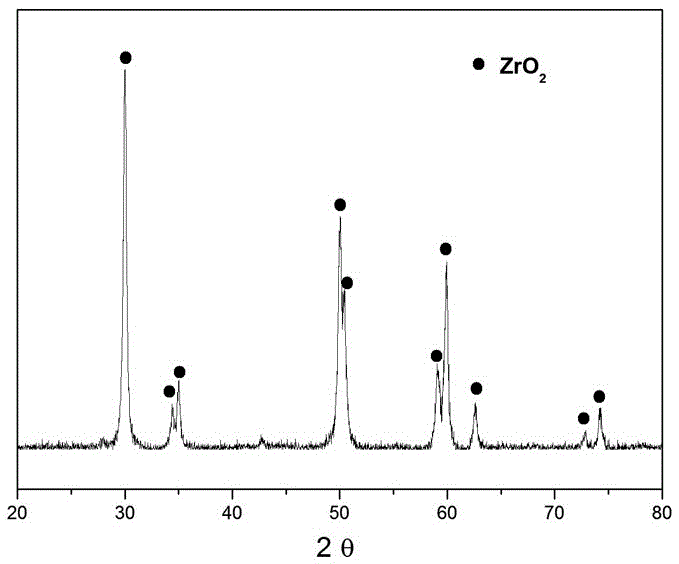

[0025] Stop stirring and stand still, take the precipitate, centrifuge wash with deionized water and absolute ethanol, filter, dry to obtain a white powder, and then bake the powder in air at 600°C for 4 hours.

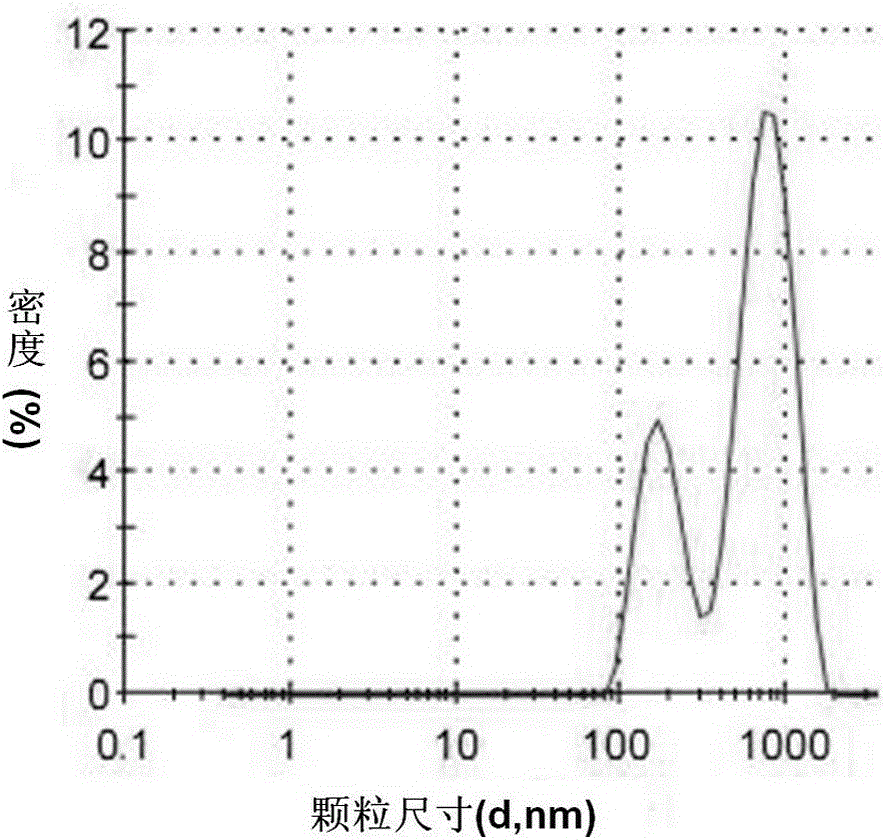

[0026] Use water as the dispersion medium, add 2% PVA binder, zirconia ball: powder = 3:1, and dry after 2 hours of ball milling time. Dry pressing at 150MPa followed by cold isostatic pressing to obtain a green body with a density of 65%.

[0027] The sinteri...

Embodiment 3

[0029] Weigh 10mmol of zirconium oxychloride, dissolve it in 10ml of deionized water, add yttrium salt according to the molar ratio of yttrium salt and zirconium salt in a ratio of 7:10, and prepare solution A; use sodium hydroxide and ammonium carbonate as precipitants , to prepare 8mol / l alkaline solution B; mix solutions A and B, stir vigorously, then add polyethylene glycol (PEG), and stir for 2 hours; stop stirring, take the precipitate, and use deionized water and anhydrous Wash with ethanol centrifugally, filter, and dry to obtain a white powder, and then the powder is calcined in air at 1000°C for 4 hours. Use water as the distribution medium, add 2% PVA binder, zirconia ball: powder = 3:1, ball mill for 5 hours, and then dry. After dry pressing at 150MPa, cold isostatic pressing obtained 70% biscuit. The sintering temperature of the final green body is 1700° C., and the temperature is kept for 5 hours. Example 3: Weigh 10 mmol of zirconium oxychloride, dissolve it i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com