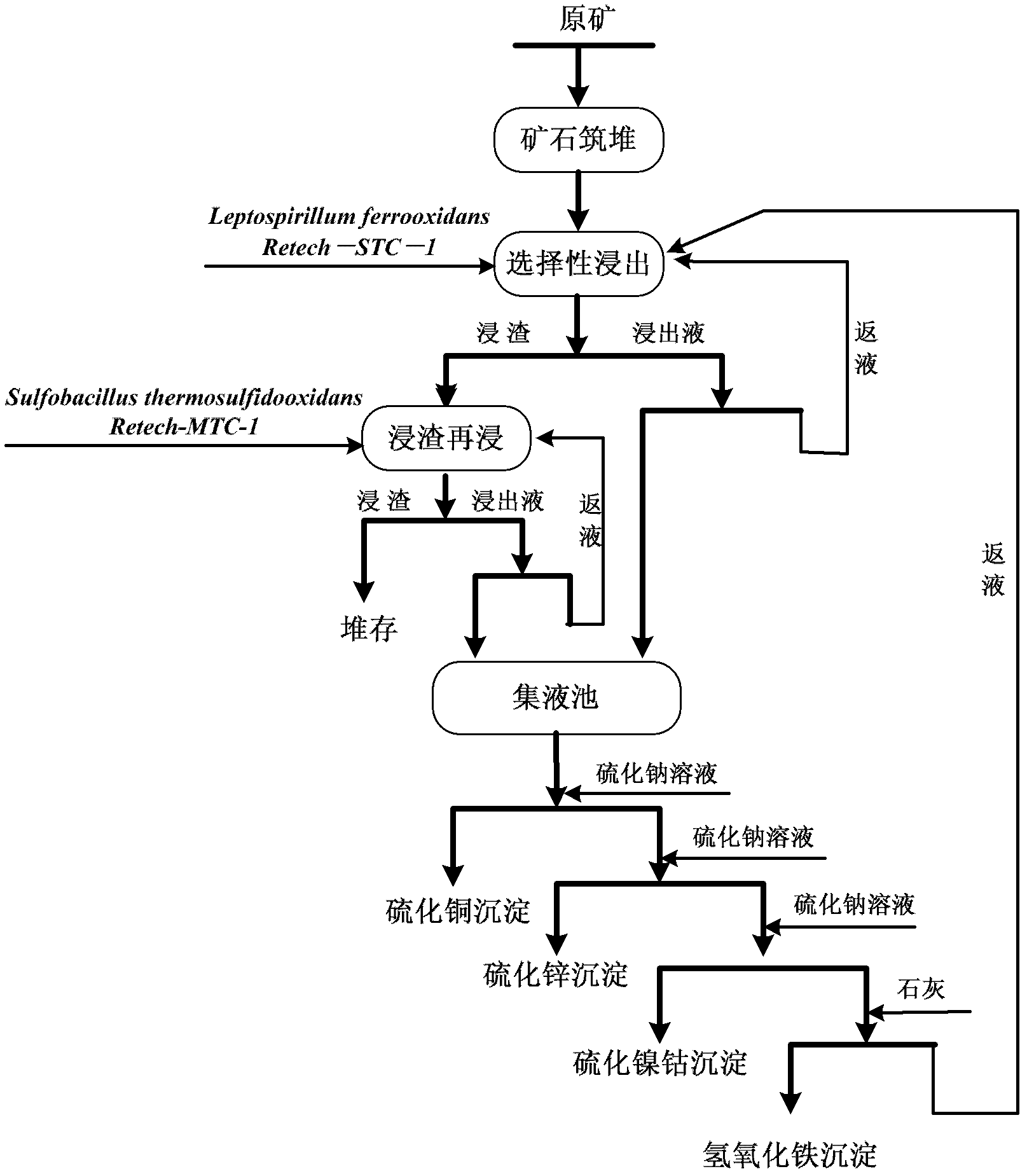

Low-grade multi-metal sulfide mineral selective bioleaching technology

A bioleaching and selective technology, applied in the direction of improving process efficiency, can solve the problems of low grade and inability to develop and utilize, and achieve the effects of low product impurity content, high product added value, and low comprehensive recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The Baishan nickel-cobalt mine in Jilin Province in China is a polymetallic sulfide ore containing valuable metals such as nickel, cobalt, zinc, and copper. The iron content is relatively high, and most of them exist in the form of pyrite. The traditional dressing and smelting technology has high economic costs. No recycling value. The main element analysis is shown in Table 1:

[0038] Table 1 Analysis of main elements of ore

[0039] element Ni co Zn Fe Cu content / % 0.24 0.04 0.45 11.22 0.18 element / % S Ca Mg SiO 2 content 7.24 5.38 6.45 56.64

[0040] The ore contains a large amount of quartz and silicate, zinc exists in the form of sphalerite, copper exists in the form of chalcopyrite, cobalt and nickel mainly exist in pentlandite and pyrite, iron mainly exists in pyrite and magnetite. Exists in the pyrite form.

[0041] (1) Laying at the bottom of the heap: at least one leachate di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com