Method for extracting various active components from dried fructus momordicae

A technology for dried Luo Han Guo and active ingredients is applied in the field of preparation of resin separation to obtain various active ingredients in Luo Han Guo, which can solve problems such as environmental pollution and resource waste, and achieve the effects of short extraction time, reduced pressure and high yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

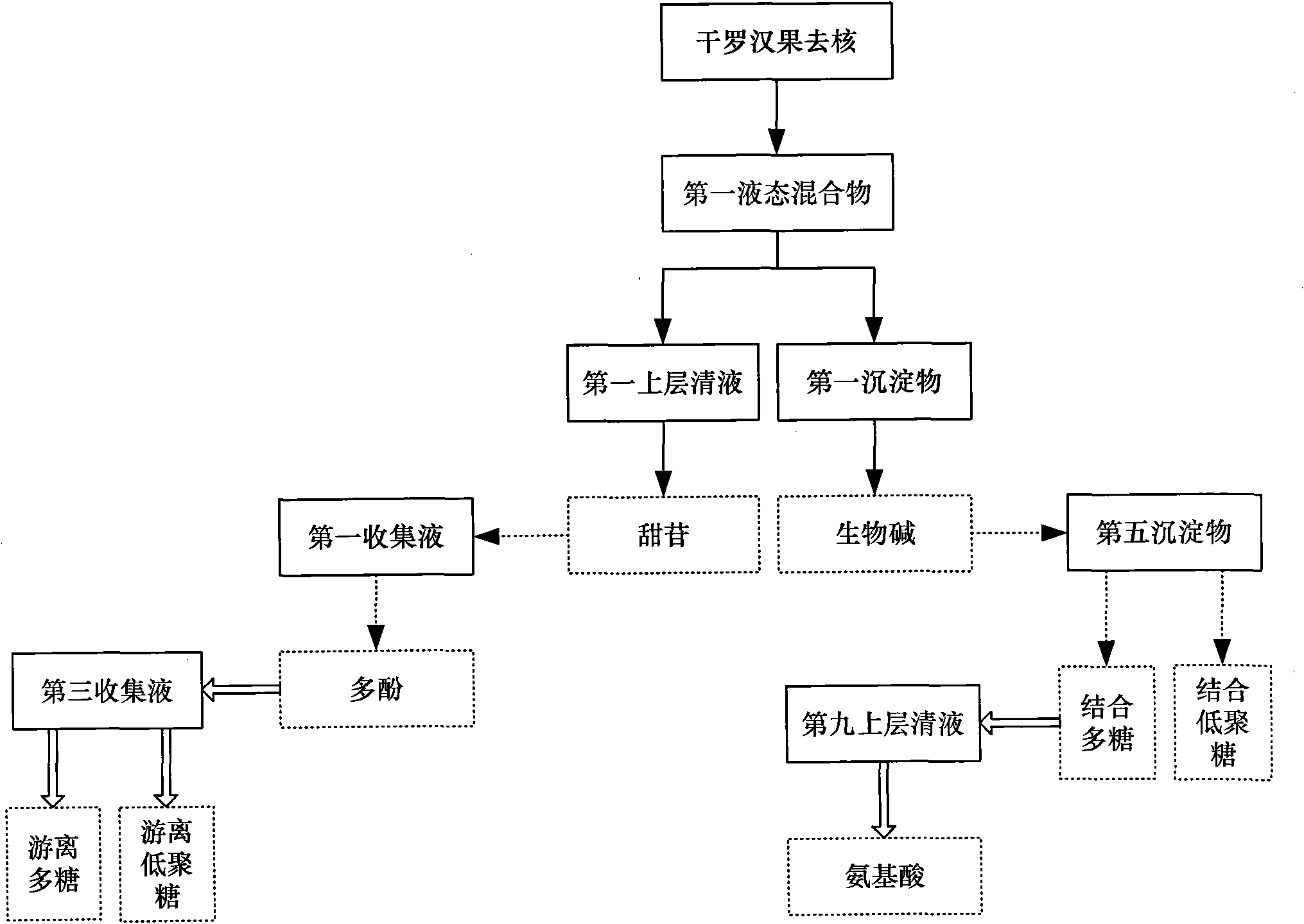

[0119] This practice extracts multiple active ingredients from dried Luo Han Guo and includes the following steps:

[0120] The first step: flash auxiliary preparation of the first liquid mixture

[0121] Put the cored dried Luo Han Guo and deionized water into a flash extraction container, soak at a temperature of 25°C for 120 minutes, stir and break at a rotation speed of 3500r / min, and homogenize for 60s to obtain the first liquid mixture;

[0122] Dosage: Add 10g of pitted and dried Luo Han Guo to 100ml of deionized water;

[0123] Step 2: Centrifugation

[0124] Put the first liquid mixture into the centrifuge tube of the centrifuge, centrifuge at a speed of 5000r / min for 15min, then remove the centrifuge tube to obtain the first supernatant and the first precipitate;

[0125] The third step: making sweet glycosides

[0126] (3-A) Add 0.65% (mass percentage concentration) of NaCl in the first supernatant liquid, then use 25%

[0127] (mass percentage concentration) Na...

Embodiment 2

[0173] This practice extracts multiple active ingredients from dried Luo Han Guo and includes the following steps:

[0174] The first step: flash auxiliary preparation of the first liquid mixture

[0175] Put the de-pitted dried Luo Han Guo and deionized water into the extraction container, soak at a temperature of 30°C for 30 minutes, stir and break at a rotation speed of 5500r / min, and homogenize for 30s to obtain the first liquid mixture;

[0176] Dosage: Add 5g of pitted and dried Luo Han Guo to 100ml of deionized water;

[0177] Step 2: Centrifugation

[0178] Put the first liquid mixture into the centrifuge tube of the centrifuge, centrifuge at a speed of 4000r / min for 20min, then remove the centrifuge tube to obtain the first supernatant and the first precipitate;

[0179] The third step: making sweet glycosides

[0180] (3-A) in the first supernatant liquid, add the NaCl of 1% (mass percentage concentration), then adjust the pH value of the first supernatant liquid ...

Embodiment 3

[0227] This practice extracts multiple active ingredients from dried Luo Han Guo and includes the following steps:

[0228] The first step: flash auxiliary preparation of the first liquid mixture

[0229] Put the cored dried Luo Han Guo and deionized water into the extraction container, soak for 90 minutes, stir and break at a rotation speed of 4500r / min, and homogenize for 45s to obtain the first liquid mixture;

[0230] Dosage: Add 15g of de-pitted dried Luo Han Guo to 100ml of deionized water;

[0231] Step 2: Centrifugation

[0232] Put the first liquid mixture into the centrifuge tube of the centrifuge, centrifuge at a speed of 4500r / min for 10min, then remove the centrifuge tube to obtain the first supernatant and the first precipitate;

[0233] The third step: making sweet glycosides

[0234] (3-A) Add 0.5% (mass percentage concentration) of NaCl in the first supernatant liquid, then adjust the pH value of the first supernatant liquid with 25% (mass percentage concen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com