Method for increasing antioxidation activity of flammulina velutipes polysaccharide

A technology of antioxidant activity and Flammulina velutipes polysaccharides, which is applied in the field of Flammulina velutipes deep processing, can solve the problems of low yield of Flammulina velutipes polysaccharides, cumbersome operations, complicated procedures, etc., achieve obvious antioxidant activity, reduce molecular weight, and have a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

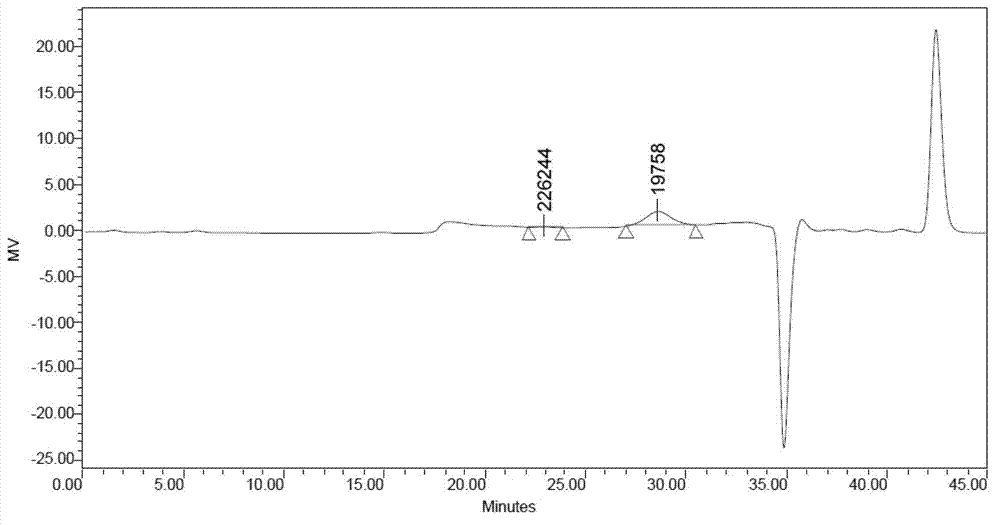

Embodiment 1

[0031] (1) Wash the Flammulina velutipes, dry them and crush them to 60 meshes to obtain raw materials.

[0032] (2) Add 3 times 95% ethanol to the dried Flammulina velutipes, heat to make the liquid slightly boil, and reflux for 2 hours. Remove impurities, filter, remove alcohol, and take the filter residue to obtain Flammulina velutipes powder.

[0033] (3) Add 20 times of distilled water to the extraction material, extract at 90°C for 1 hour, filter, repeat the extraction once, and separate the residue of Flammulina velutipes to obtain the extract.

[0034] (4) Add 3 times Sevag reagent (chloroform:butanol=5:1) to the extract to remove protein, shake vigorously for 30 minutes, then let stand for 10 minutes, centrifuge, and repeat protein removal 3 times.

[0035] (5) Vacuum-concentrate the extract to 1 / 7 of its original volume to obtain a concentrate. Then add ethanol so that the final concentration of ethanol is 80% (v / v), mix well, let stand at 0-4°C for 6 hours, filter...

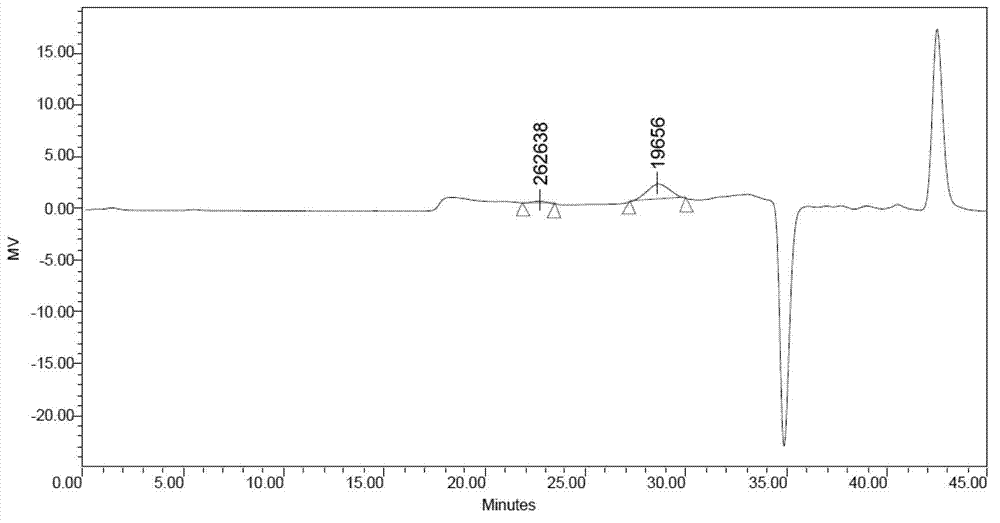

Embodiment 2

[0039] (1) Wash the Flammulina velutipes, dry them and crush them to 80 meshes to obtain raw materials.

[0040] (2) Add 5 times 95% ethanol to the dried Flammulina velutipes, heat to make the liquid slightly boil, and reflux for 3 hours. Remove impurities, filter, remove alcohol, and take the filter residue to obtain Flammulina velutipes powder.

[0041] (3) Add 25 times of distilled water to the extracted raw materials, extract at 95°C for 2 hours, filter, repeat the extraction once, and separate the residue of Flammulina velutipes to obtain the extract.

[0042] (4) Add 4 times Sevag reagent (chloroform:butanol=5:1) to the extract to remove protein, shake vigorously for 45 minutes, then let stand for 10 minutes, centrifuge, and repeat protein removal 3 times.

[0043] (5) Vacuum-concentrate the extract to 1 / 5 of the original volume to obtain a concentrate. Then add ethanol so that the final concentration of ethanol is 75% (v / v), mix well, let stand at 0-4°C for 10 hours, ...

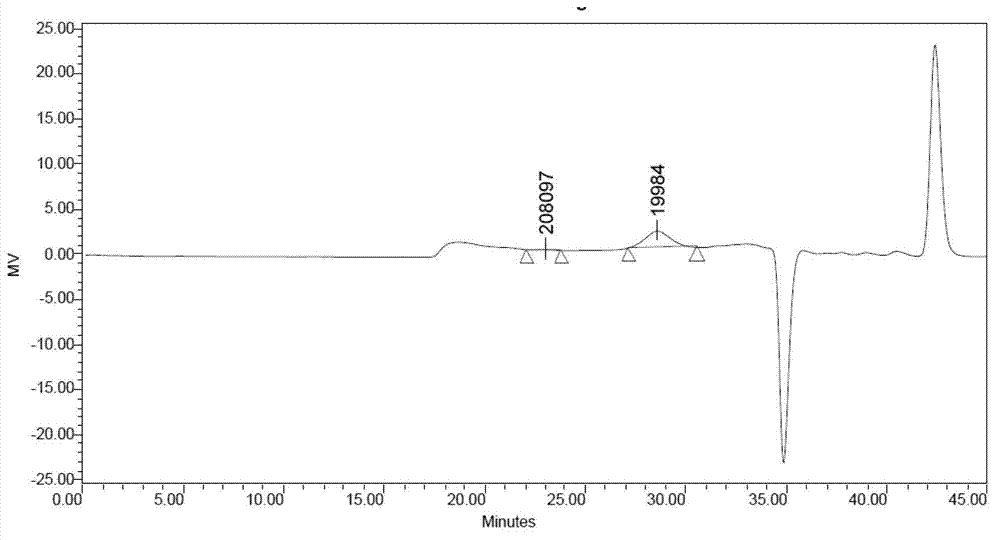

Embodiment 3

[0047] (1) Wash the Flammulina velutipes, dry them and crush them to 60 meshes to obtain raw materials.

[0048] (2) Add 6 times of 95% ethanol to the dried Flammulina velutipes, heat to make the liquid slightly boil, and reflux for 4 hours. Remove impurities, filter, remove alcohol, and take the filter residue to obtain Flammulina velutipes powder.

[0049] (3) Add 30 times of distilled water to the extracted raw materials, extract at 100°C for 3 hours, filter, repeat the extraction once, and separate the residue of Flammulina velutipes to obtain the extract.

[0050] (4) Add 5 times Sevag reagent (chloroform:butanol=5:1) to the extract to remove protein, shake vigorously for 60 minutes, then let stand for 10 minutes, centrifuge, and repeat protein removal 3 times.

[0051] (5) Vacuum-concentrate the extract to 1 / 3 of the original volume to obtain a concentrate. Then add ethanol so that the final concentration of ethanol is 85% (v / v), mix well, let stand at 0-4°C for 12 hours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com