A kind of extraction method of fungus polysaccharide

A technology of ground fungus and polysaccharides, which is applied in the field of extraction of ground fungus polysaccharides, can solve the problems of large loss of raw materials, complicated preparation process, and low extraction rate of polysaccharides, and achieve reduced raw material costs, simple operation methods, high extraction rates and recovery rates Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

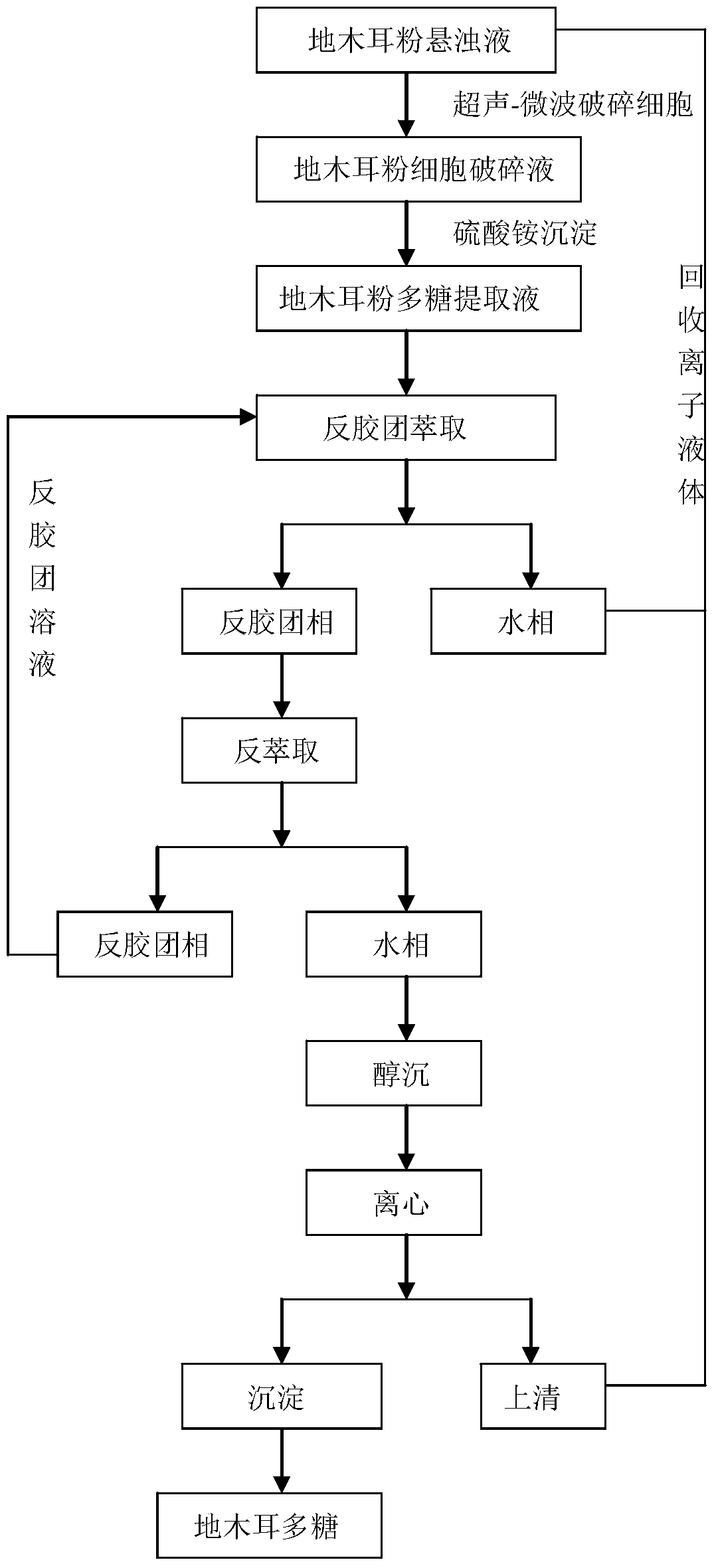

[0052] A method for extracting polysaccharides from fungus, such as figure 1 shown, including the following steps:

[0053] (1) Preparation of ground fungus powder suspension: 100 g of ground fungus powder was dissolved in [Bmim]Cl ionic liquid with a concentration of 0.4 mol / L, and extracted for 30 minutes to prepare ground fungus powder suspension.

[0054] (2) Preparation of ground fungus cell crushing solution: use ultrasonic-microwave combined reaction system to crush the ground fungus powder cells in the prepared ground fungus powder suspension, set the ultrasonic power to 150w, ultrasonic treatment time 8min; microwave power to 160w , microwave heating treatment time 3min, during microwave heating treatment, adopt intermittent treatment mode, heating 1min, intermittent 1min, centrifugation treatment 15min with the speed of 3500rpm afterwards, take supernatant, obtain the ground fungus cell broken liquid.

[0055] (3) Preparation of crude extract of Auricularia auricula...

Embodiment 2

[0062] Weigh 100g of ground fungus powder, add 15 times the amount of 0.3mol / L ionic liquid, and extract at room temperature for 30 minutes; at 100w ultrasonic power, 5min ultrasonic time, 150w microwave power, microwave heating adopts intermittent treatment, heating 1min, intermittent 1min, microwave Treat for 3 minutes, centrifuge at 3000 rpm for 15 minutes to obtain supernatant;

[0063] Add ammonium sulfate to the supernatant to make the saturation 70%, let stand at 4°C for 2 hours, centrifuge at 5000 rpm for 10 minutes, and take the supernatant to obtain the crude extract of Auricularia polysaccharide;

[0064] The crude polysaccharide extract and the reverse micelles solution were fully mixed according to V / V=1:1, extracted for 30 minutes, and centrifuged at 2000rpm for 5 minutes to obtain the reverse micelles phase; the reverse micelles solution was chloroform with a volume ratio of 1:1 After mixing with n-butanol, add TOMAC to make a mixed solution with a final concent...

Embodiment 3

[0069] Weigh 100g of ground fungus powder, add 25 times the amount of 0.7mol / L ionic liquid, and extract at room temperature for 50 minutes; at 200w ultrasonic power, 10min ultrasonic time, 200w microwave power, microwave heating adopts intermittent treatment, heating 1min, intermittent 1min, microwave Treat for 5 minutes, centrifuge at 5000 rpm for 20 minutes to obtain supernatant;

[0070] Add ammonium sulfate to the supernatant to make the saturation 70%, let stand at 8°C for 2 hours, centrifuge at 7000rpm for 15 minutes, and take the supernatant to obtain the crude extract of Auricularia polysaccharide;

[0071] The crude polysaccharide extract and the reverse micelles solution were fully mixed according to V / V=2:1, extracted for 60 minutes, and centrifuged at 3000rpm for 10 minutes to obtain the reverse micelles phase; wherein the reverse micelles solution was chloroform with a volume ratio of 4:1 After mixing with n-butanol, add TOMAC to make a mixed solution with a conc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com