Device and method for extracting delicious mushroom polysaccharide

The technology of a mushroom polysaccharide and an extraction device is applied in the field of the delicious mushroom polysaccharide extraction device, and can solve the problems of reduced extraction rate, extraction influence, easily destroyed polysaccharide adhesion, coking and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

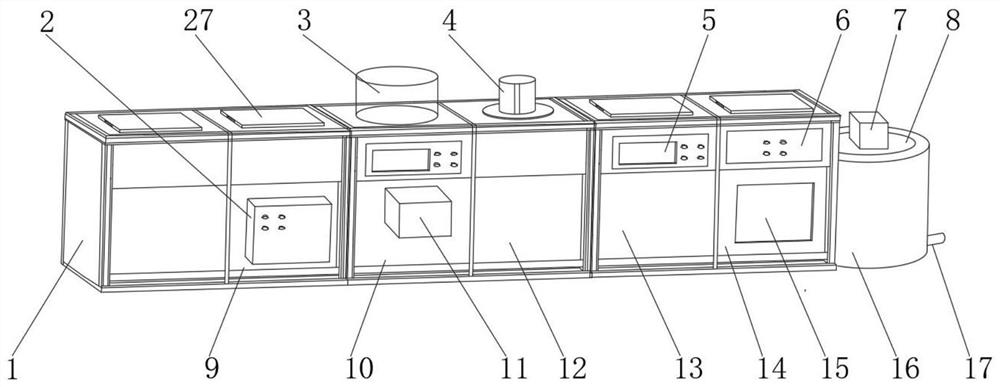

[0035] Such as Figure 1-4 Shown, a kind of delicacy mushroom polysaccharide extracting device comprises precooling box 1, freezing box 9, vacuum drying device 10, grinding device 12, weighing device 13, ultrasonic crushing device 14, centrifugal device 16, and the front end of freezing box 9 is installed Control box 2 is arranged, the upper end of precooling box 1, freezing box 9, weighing device 13, ultrasonic crushing device 14 is all equipped with sealing cover plate 27, and the front end of weighing device 13 is equipped with control panel 5, and the upper end of ultrasonic crushing device 14 The front end is equipped with control mechanism 6 and observation window 15, and the inboard of centrifugal device 16 is equipped with centrifugal inner cylinder 8, and the top of centrifugal inner cylinder 8 is equipped with driving cylinder 7, and the outer wall of centrifugal device 16 is equipped with discharge pipe 17.

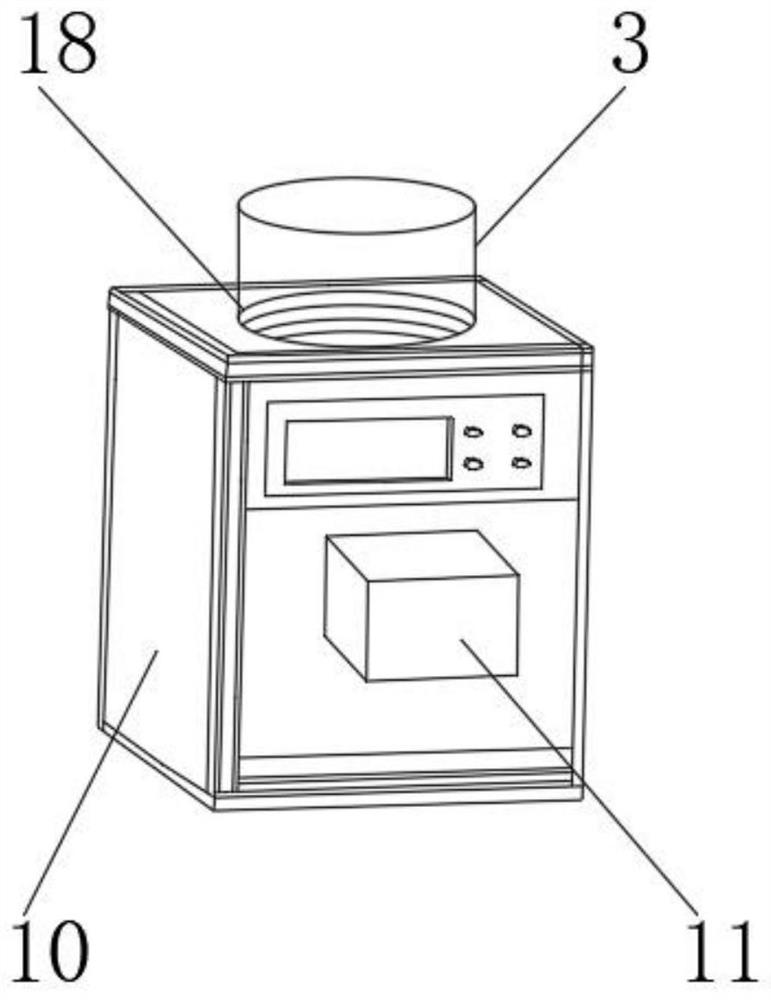

[0036] The front end of vacuum drying device 10 is equipp...

Embodiment 2

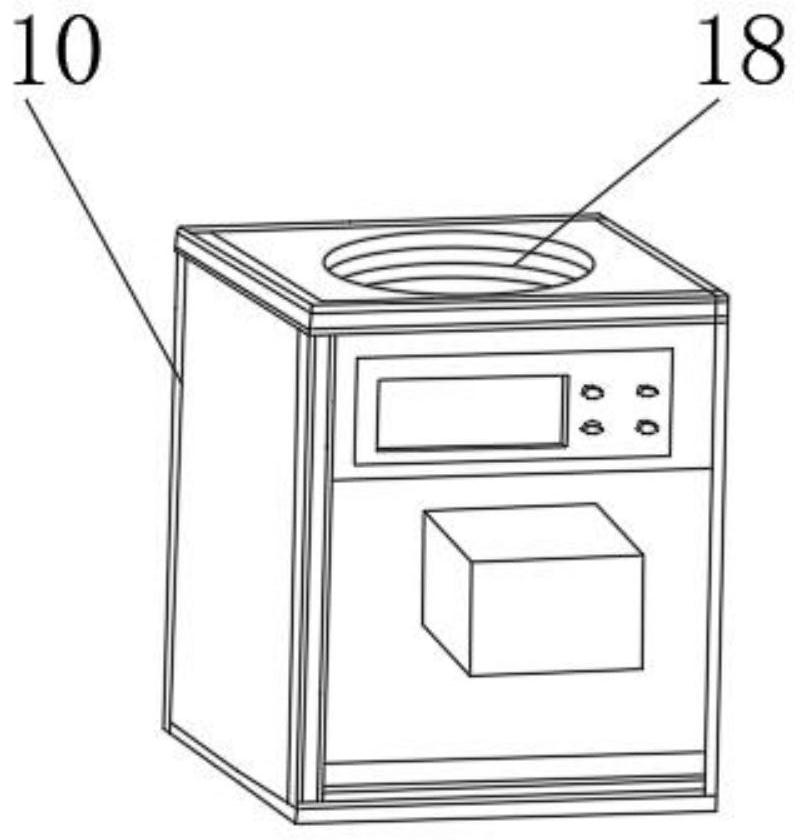

[0046] On the basis of Example 1, as figure 1 , 5 , shown in 6, a kind of delicacy mushroom polysaccharide extracting device, comprises pre-cooling box 1, freezer 9, vacuum drying device 10, grinding device 12, weighing device 13, ultrasonic crushing device 14, centrifugal device 16, freezer 9 The front end is equipped with a control box 2, the upper ends of the pre-cooling box 1, the freezer 9, the weighing device 13, and the ultrasonic crushing device 14 are equipped with a sealing cover 27, and the front end of the weighing device 13 is equipped with a control panel 5, and the ultrasonic crushing device The front end of 14 is equipped with control mechanism 6 and observation window 15, and the inboard of centrifugal device 16 is equipped with centrifugal inner cylinder 8, and the top of centrifugal inner cylinder 8 is equipped with driving cylinder 7, and the outer wall of centrifugal device 16 is equipped with discharge pipe 17.

[0047] The upper end of grinding device 1...

Embodiment 3

[0057] On the basis of Example 2, such as figure 1 , 7 Shown, a kind of delicacy mushroom polysaccharide extracting device comprises precooling box 1, freezing box 9, vacuum drying device 10, grinding device 12, weighing device 13, ultrasonic crushing device 14, centrifugal device 16, and the front end of freezing box 9 is installed Control box 2 is arranged, the upper end of precooling box 1, freezing box 9, weighing device 13, ultrasonic crushing device 14 is all equipped with sealing cover plate 27, and the front end of weighing device 13 is equipped with control panel 5, and the upper end of ultrasonic crushing device 14 The front end is equipped with control mechanism 6 and observation window 15, and the inboard of centrifugal device 16 is equipped with centrifugal inner cylinder 8, and the top of centrifugal inner cylinder 8 is equipped with driving cylinder 7, and the outer wall of centrifugal device 16 is equipped with discharge pipe 17.

[0058] The control box 2, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com