Preparation device and preparation method of delicious mushroom polysaccharide product

A technology of mushroom polysaccharide and preparation device, which is applied in centrifuges, grain processing, centrifuges with rotating drums, etc., can solve the problems of extraction influence, unfavorable use, large physical grinding particles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

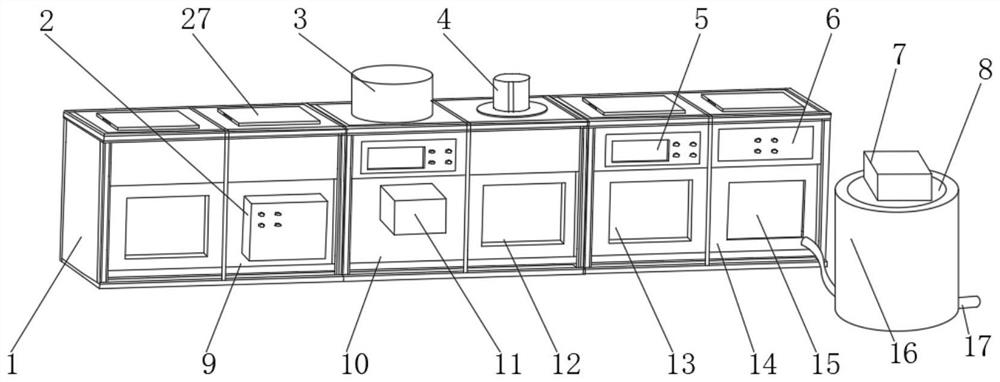

[0034] like Figure 1-4 As shown, a preparation device for delicious mushroom polysaccharide products includes a pre-cooling box 1, a freezing box 9, a vacuum drying device 10, a grinding device 12, a weighing device 13, an ultrasonic crushing device 14, a centrifugal device 16, and the front end of the freezing box 9 The control box 2 is installed, the upper end of the precooling box 1, the freezer 9, the weighing device 13, and the ultrasonic crushing device 14 are equipped with a sealing cover plate 27, and the front end of the weighing device 13 is equipped with a control panel 5, and the ultrasonic crushing device 14 A control mechanism 6 and an observation window 15 are installed on the front end of the centrifugal device 16, a centrifugal inner cylinder 8 is installed on the inner side of the centrifugal device 16, a driving cylinder 7 is installed on the top of the centrifugal inner cylinder 8, and a discharge pipe 17 is installed on the outer wall of the centrifugal de...

Embodiment 2

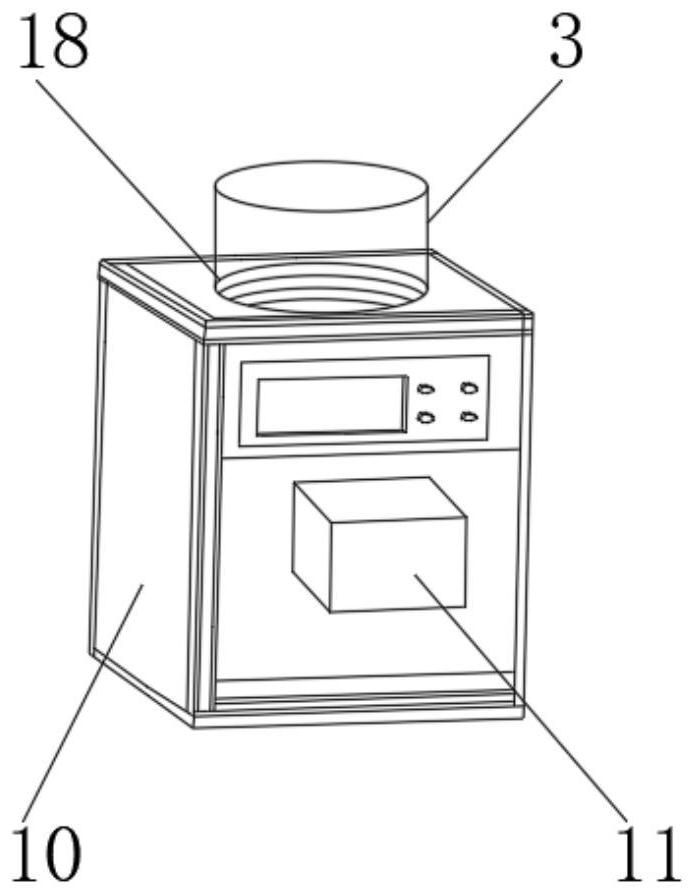

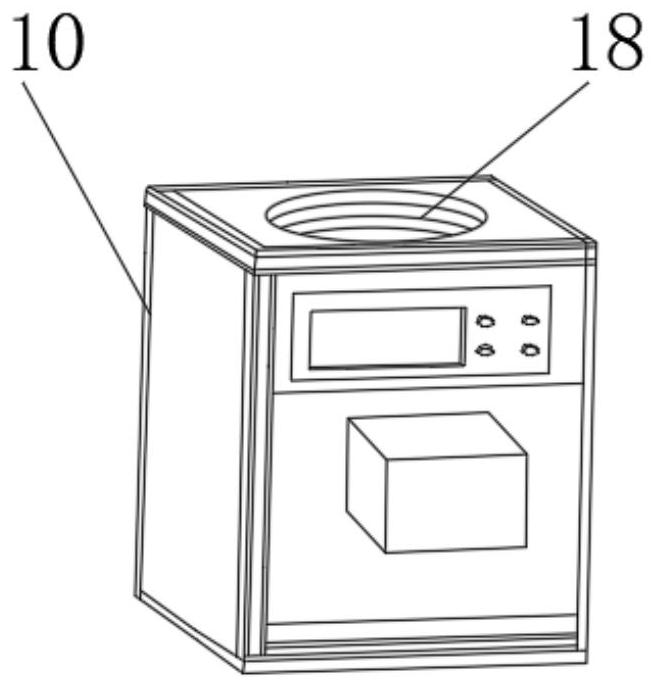

[0044] On the basis of Example 1, as figure 1 , 5 , shown in 6, a kind of delicious mushroom polysaccharide product preparation device comprises pre-cooling box 1, freezer 9, vacuum drying device 10, grinding device 12, weighing device 13, ultrasonic crushing device 14, centrifugal device 16, freezer 9 The front end of the control box 2 is installed, the upper end of the pre-cooling box 1, the freezer 9, the weighing device 13, and the ultrasonic crushing device 14 are all equipped with a sealing cover 27, and the front end of the weighing device 13 is equipped with a control panel 5, ultrasonic crushing The front end of device 14 is equipped with control mechanism 6 and observation window 15, and the inboard of centrifugal device 16 is equipped with centrifugal inner cylinder 8, and the top of centrifugal inner cylinder 8 is equipped with driving cylinder 7, and the outer wall of centrifugal device 16 is equipped with discharge pipe 17.

[0045] The upper end of grinding dev...

Embodiment 3

[0055] On the basis of Example 2, such as figure 1 , 7 As shown, a preparation device for delicious mushroom polysaccharide products includes a pre-cooling box 1, a freezing box 9, a vacuum drying device 10, a grinding device 12, a weighing device 13, an ultrasonic crushing device 14, a centrifugal device 16, and the front end of the freezing box 9 The control box 2 is installed, the upper end of the precooling box 1, the freezer 9, the weighing device 13, and the ultrasonic crushing device 14 are equipped with a sealing cover plate 27, and the front end of the weighing device 13 is equipped with a control panel 5, and the ultrasonic crushing device 14 A control mechanism 6 and an observation window 15 are installed at the front end of the centrifugal device 16, a centrifugal inner cylinder 8 is installed on the inboard of the centrifugal device 16, a driving cylinder 7 is installed on the top of the centrifugal inner cylinder 8, and a discharge pipe 17 is installed on the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com