Method for recycling valuable metal from copper smelting white smoke

A valuable metal, white smoke technology, applied in the direction of improving process efficiency, can solve problems such as insufficient utilization, environmental pollution, large amount of fossil fuel or power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

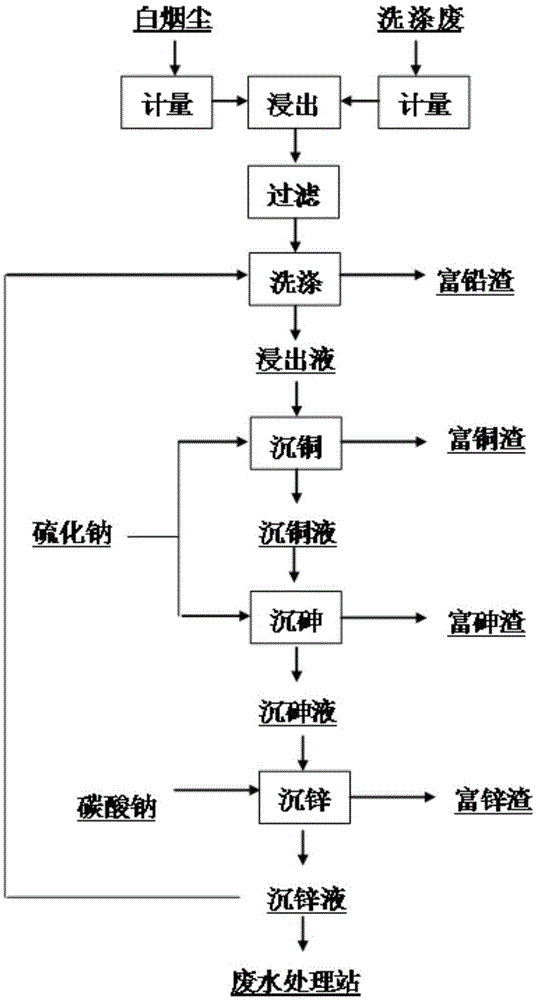

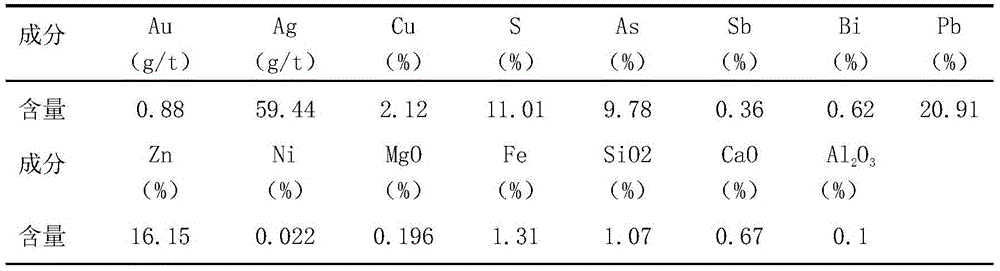

[0032] Such as figure 1 Shown: (1) Main components of white soot ash and primary power wave cycle waste acid are shown in Tables 1 and 2;

[0033] Table 1 Main components of white soot

[0034]

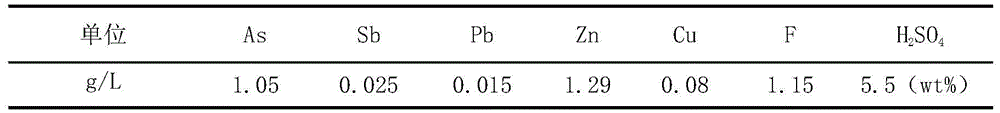

[0035] Table 2 Main components of waste acid in primary power wave cycle

[0036]

[0037] (2) Take 40 tons of primary power wave circulating waste acid and pump it into the leaching tank, then add 5 tons of white smoke and dust, stir and leaching for 30 minutes at room temperature, filter, wash the filter cake with 1.5 tons of zinc-precipitating liquid and incorporate it into the filtrate , after analysis, copper, zinc, arsenic content are respectively in the filtrate: 2.7g / L, 21.5g / L, 13.3g / L; The filter cake weight of dry basis is 1120kg, and lead content is 43.6wt%, and lead recovery rate is greater than 95.5%, the dissolution rates of copper, zinc and arsenic are 92.6%, 97.5% and 95.5% respectively;

[0038] (3) Take 40m of pickling solution 3 According to 0.8 times the...

Embodiment 2

[0042] (1) The main components of white soot and ash and primary power wave cycle waste acid are shown in Tables 3 and 4;

[0043] Table 3 Main components of white soot

[0044]

[0045] Table 4 Main components of waste acid in primary power wave cycle

[0046]

[0047] (2) Take 40 tons of primary power wave circulating waste acid and pump it into the leaching tank, then add 5 tons of white smoke and dust, stir and leaching for 30 minutes at room temperature, filter, wash the filter cake with 1.5 tons of zinc-precipitating liquid and incorporate it into the filtrate , after analysis, copper, zinc, arsenic content are respectively in the filtrate: 2.9g / L, 23.3g / L, 13.2g / L; The dry basis filter cake quality is 1265kg, and lead content is 40.2wt%, and lead recovery rate is greater than 95.7%, the dissolution rates of copper, zinc and arsenic are 92.8%, 98.6% and 95.1% respectively;

[0048] (3) Take 40m3 of acid leaching solution, add 1.0 times the theoretical amount requ...

Embodiment 3

[0052] (1) The main components of white soot and ash and primary power wave cycle waste acid are shown in Tables 5 and 6;

[0053] Table 5 Main components of white soot

[0054]

[0055] Table 6 Main components of waste acid in primary power wave cycle

[0056]

[0057] (2) Take 40 tons of primary power wave circulating waste acid and pump it into the leaching tank, then add 4 tons of white smoke ash, stir and leaching for 30 minutes at room temperature, filter, wash the filter cake with 1.5 tons of zinc-precipitating liquid and incorporate it into the filtrate , after analysis, copper, zinc, arsenic content are respectively in the filtrate: 2.3g / L, 18.6g / L, 11.5g / L; The filter cake weight of dry basis is 811kg, and lead content is 48.2wt%, and lead recovery rate is greater than 95.5%, the dissolution rates of copper, zinc and arsenic are 92.6%, 97.5% and 95.5% respectively;

[0058] (3) Get 40m3 of pickling solution, add 182kg of solid sodium sulfide with an effective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com