Method for cogeneration of TiO2 and Al2O3 by using titanium-bearing blast furnace slag mineralized carbon dioxide

A technology of carbon dioxide and blast furnace slag, applied in the direction of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the problems of storage and transportation difficulties, waste of titanium resources, no recycling, etc., and achieve simple process, low cost, The effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

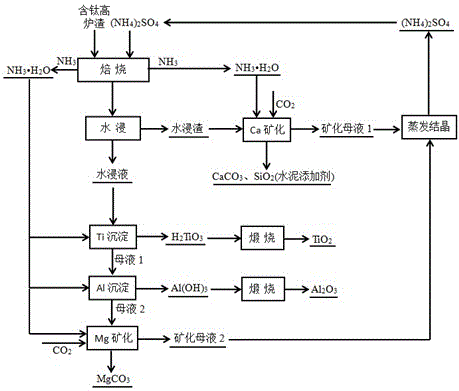

Method used

Image

Examples

Embodiment 1

[0028] (1) Grind the titanium-containing blast furnace slag to -150 μm and mix it evenly with ammonium sulfate, and control the mass ratio of titanium-containing blast furnace slag and ammonium sulfate to 1:4.

[0029] (2) Place the mixture obtained in step (1) in a tube furnace, heat up to 350°C at a rate of 10°C / min, and continue roasting for 150 minutes. The gas is absorbed by water.

[0030] (3) Extract the roasted slag obtained in step (2) with water, stir in a water bath at a constant temperature of 40°C for 240 minutes, control the liquid-solid ratio (g / g) to 1:1, and filter the obtained product to obtain rich The water immersion solution of titanium aluminum magnesium metal ions and the main component is CaSO 4 and SiO 2 of water leaching residue.

[0031] (4) Adjust the water leaching slag obtained in step (3) and the ammonia water obtained in step (2) into a slurry, control the molar ratio of calcium sulfate and ammonia in the water leaching slag to 1:2, pass in c...

Embodiment 2

[0039] (1) Grind the titanium-containing blast furnace slag to -75 μm and mix it evenly with ammonium sulfate, and control the mass ratio of titanium-containing blast furnace slag and ammonium sulfate to 1:7.

[0040] (2) Put the mixture obtained in step (1) in a tube furnace, heat up to 250°C at a rate of 10°C / min and roast for 240 minutes. After the reaction, the roasted slag obtained is cooled to room temperature, and the ammonia gas generated during the roasting process is absorbed by water. .

[0041] (3) The roasted slag obtained in step (2) was leached with water, stirred at a constant temperature of 60°C in a water bath for 90 minutes, and the liquid-solid ratio (g / g) was controlled at 6:1, and the obtained product was separated by suction filtration to obtain rich The water immersion solution of titanium aluminum magnesium metal ions and the main component is CaSO 4 and SiO 2 of water leaching residue.

[0042] (4) Adjust the water leaching slag obtained in step (3...

Embodiment 3

[0049] (1) Grind the titanium-containing blast furnace slag to -45 μm and mix it evenly with ammonium sulfate, and control the mass ratio of titanium-containing blast furnace slag and ammonium sulfate to 1:15.

[0050] (2) Put the mixture obtained in step (1) in a tube furnace, heat up to 450°C at a rate of 10°C / min and roast for 30 minutes. After the reaction, the roasted slag obtained is cooled to room temperature, and the ammonia gas generated during the roasting process is absorbed by water. .

[0051] (3) The roasted slag obtained in step (2) was leached with water, stirred in a water bath at a constant temperature of 75°C for 30 minutes, and the liquid-solid ratio (g / g) was controlled at 3:1, and the obtained product was separated by suction filtration to obtain rich The water immersion solution of titanium aluminum magnesium metal ions and the main component is CaSO 4 and SiO 2 of water leaching residue.

[0052] (4) Adjust the water leaching slag obtained in step (3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com