MoO3-SnO2 base doped nano composite metal oxide and method for producing the same

A nano-composite and composite metal technology, used in instruments, measuring devices, scientific instruments, etc., can solve the problems of poor thermal stability and unsatisfactory selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A. Weigh 1.7529g of SnCl 4 ·5H 2 O was fully dissolved in 100ml distilled water to prepare 0.05M SnCl 4 solution, add dilute ammonia solution drop by drop under constant stirring, stop the dropwise addition when the pH value of the solution reaches 8, and obtain α-stannic acid sol precipitation, then place it for aging for 2 hours, filter and wash to remove Cl - , Disperse and dissolve the filtered sol in 50ml distilled water to make the concentration 0.1M.

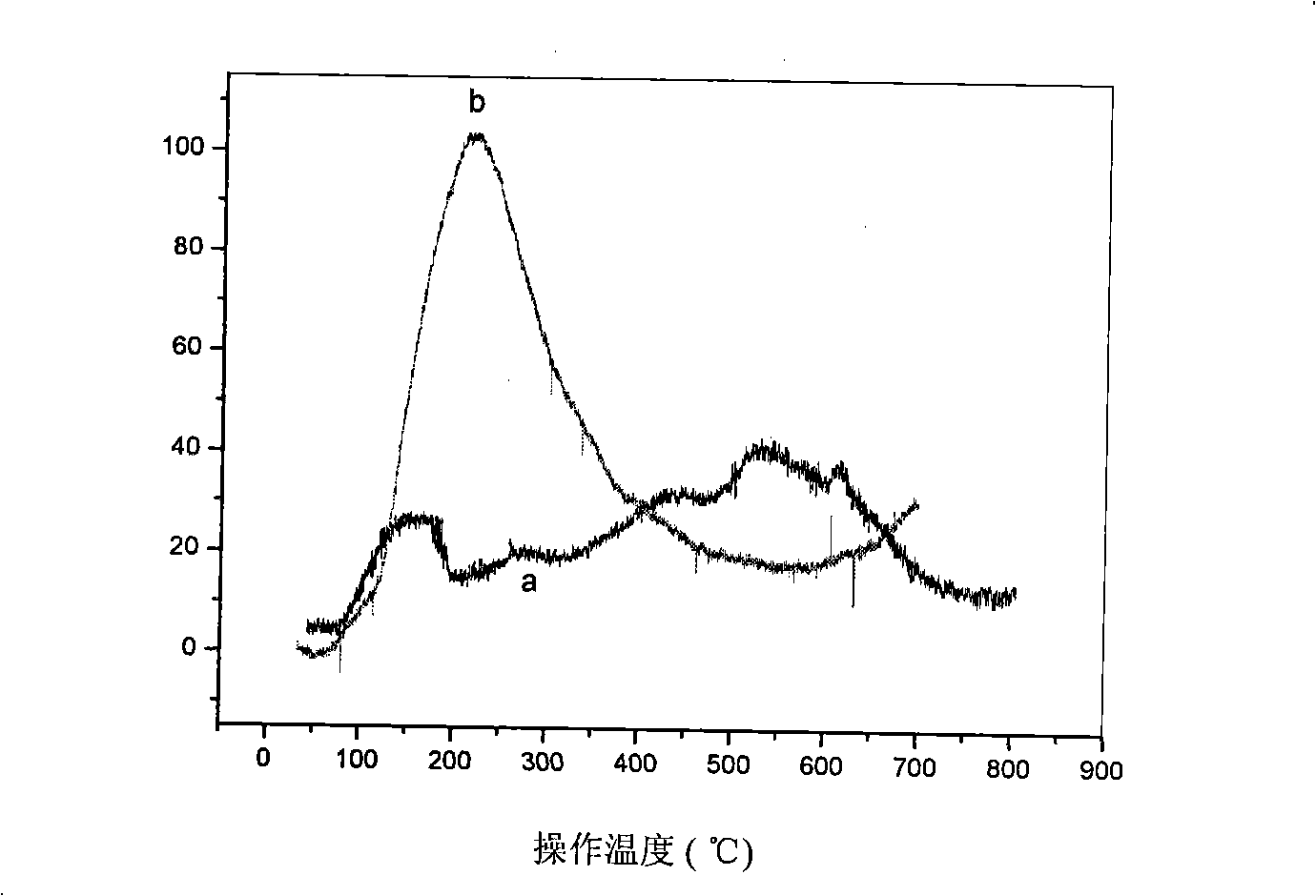

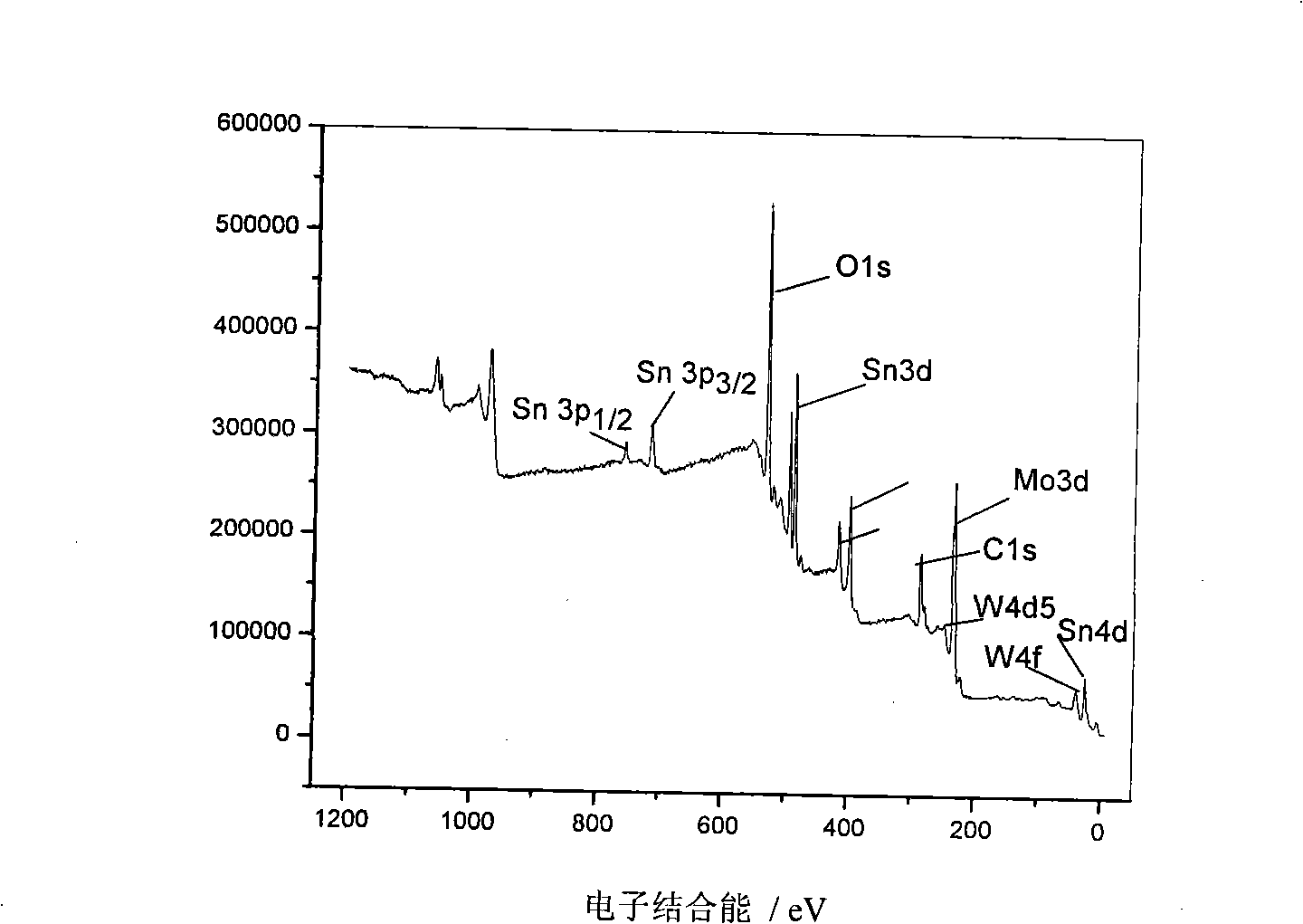

[0023] B. Weigh 1.3241g of (NH 4 ) 6 Mo 7 o 24 4H 2 O was dissolved in 75ml of water to make a concentration of 0.1M (NH 4 ) 6 Mo 7 o 24 4H 2 O solution, adjust the pH to 1 with nitric acid solution to convert it into a molybdic acid solution, and then add it dropwise to the above 50ml α-stannic acid sol solution to make the precipitation complete, leave it at room temperature for aging for 24 hours, and centrifuge at 4200rmp , dry the separated precipitate at 70°C, and roast at 600°C for 6 hours to obt...

Embodiment 2

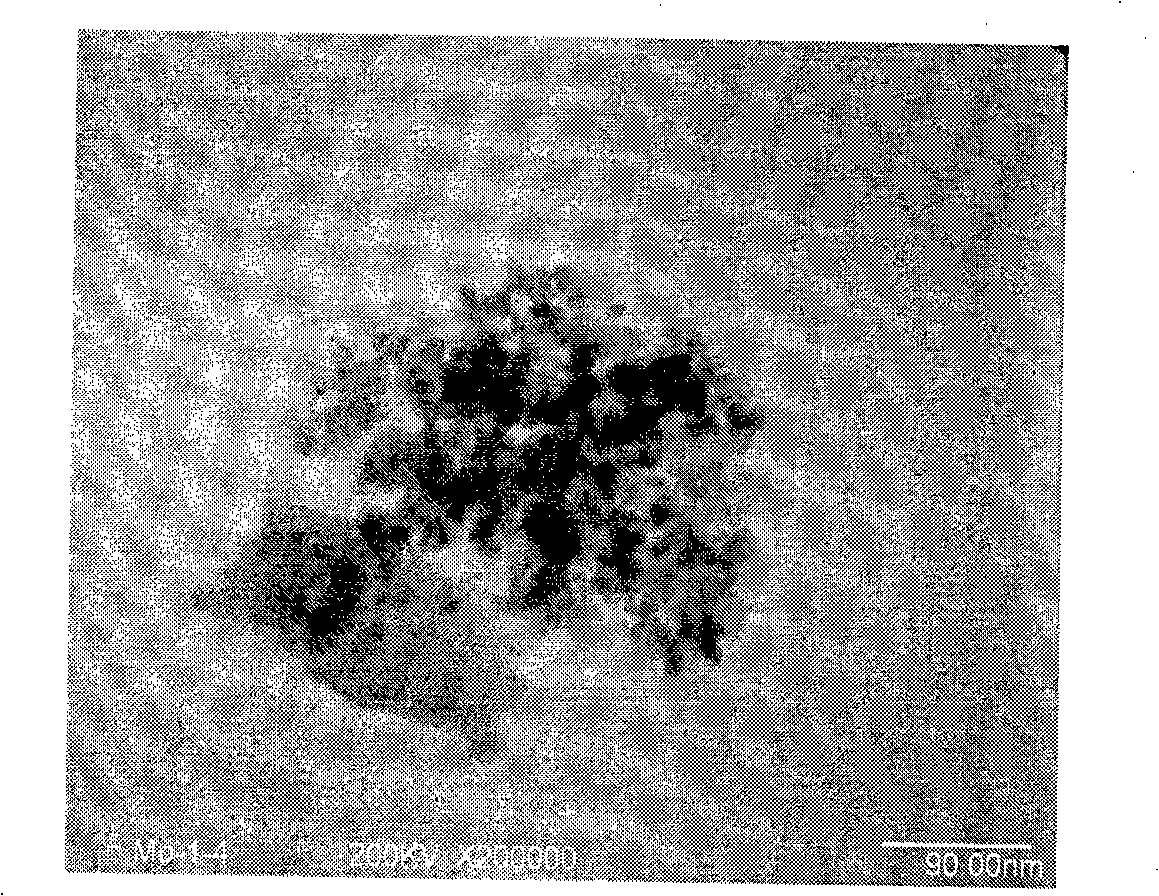

[0025] A. with embodiment 1;

[0026] B. Add 0.2207g of (NH 4 ) 6 Mo 7 o 24 4H 2 O is dissolved in 12.5ml of distilled water, adjusted with nitric acid solution to make the pH value 1, and then added dropwise to the above-mentioned 50ml α-stannoic acid sol solution to make it precipitate completely. Others are the same as in Example 1, and finally obtain Sn / Mo MoO with a molar ratio of 4:1 3 -SnO 2 Composite powder. The measured average grain size of the material is about 13nm, and the specific surface area is 33m 2 / g.

Embodiment 3

[0028] A. Weigh 1.7529g of SnCl 4 ·5H 2 O and 0.0297 g of PdCl 2 Fully dissolved in 100ml distilled water to prepare 0.05M SnCl 4 and PdCl 2 Solution, add dilute ammonia solution drop by drop under constant stirring, stop dropping when the pH value of the solution reaches 8, and obtain the α-stannic acid sol precipitation containing a small amount of Pd, then place it for aging for 2 hours, filter, and disperse the filtered sol Dissolve in 50ml distilled water to make the concentration 0.1M;

[0029] B. The same as in Example 1, except that it is aged at room temperature for 12 hours, and baked at 600°C for 6 hours to obtain a composite powder PdO-MoO doped with PdO 3 -SnO 2 , wherein the mass ratio of Pd / Sn is 0.03:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com