Method and device for treating and recycling copper-containing acid wastewater of mines

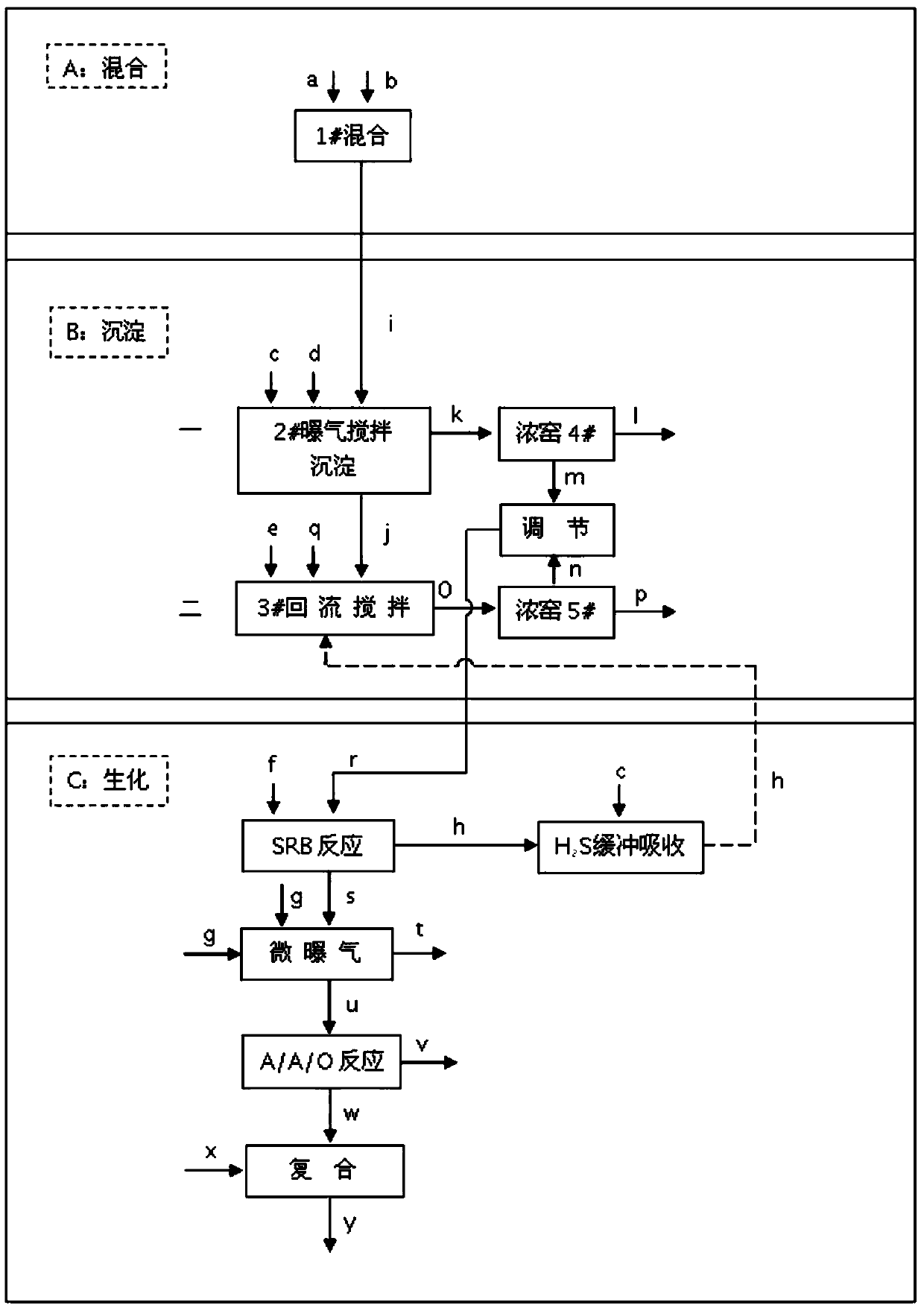

A technology of acid wastewater and recycling, applied in mining wastewater treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve the problem of low pH value of multi-stage reflux, adverse effects of heavy metal grading and precipitation, and poor process controllability To achieve the effect of reducing the cost of medicines, maximizing the utilization of resources and improving technical feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

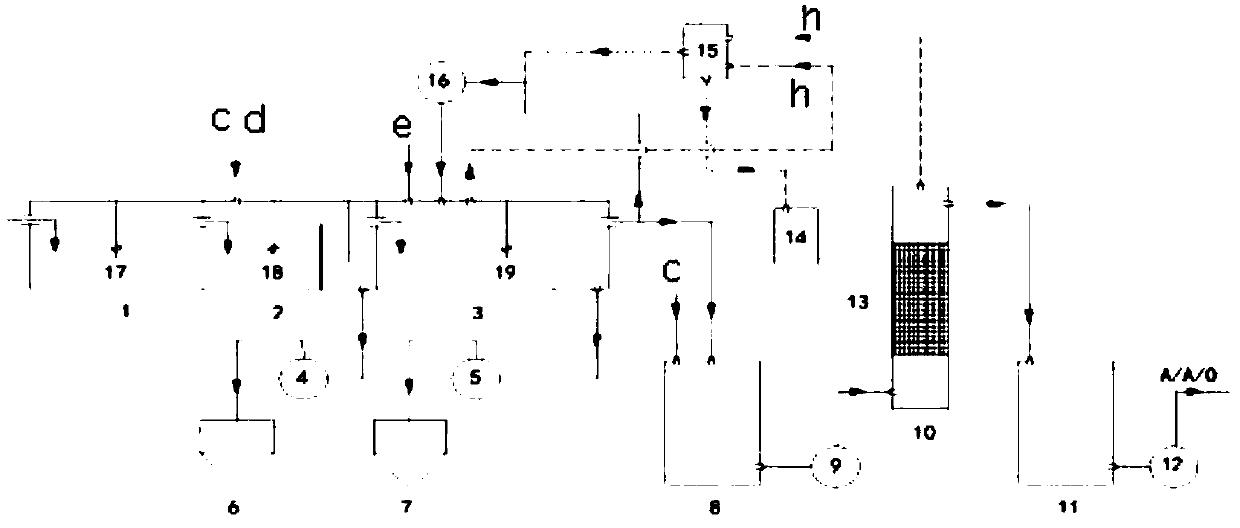

[0043] Mix pit water a and raffinate b in 1# stirring tank 1 according to the volume ratio of 10:1, pump the mixed wastewater i into 2# aeration mixing tank 2, the mixed wastewater i contains Cu 2+ =450mg / L, Fe=3.5g / L, Al=0.35g / L, Cond=9000μs / cm, SO 4 2- =4500mg / L; add sodium hydroxide c and calcium hydroxide d to the 2# stirring tank 2, control the dosage of sodium hydroxide c to 6.8kg / t, and the dosage of calcium hydroxide d to 0.82kg / t , introduce air through the rotation of self-priming agitator 19 simultaneously to realize the aeration intensified neutralization reaction, control the reaction end point pH=3.5, the reaction time is 30min, separate the aeration supernatant j and iron-containing precipitate k, and iron-containing The precipitate k is pumped to the thickener 6 for treatment, and the dehydrated iron-containing neutralized slag 1 and the supernatant 1 m are obtained; the supernatant 1 m overflows to the No. 3 reflux stirring sedimentation tank 3, and anionic f...

Embodiment 2

[0045] The pit water and the raffinate are mixed in the 1# mixing tank 1 according to the volume ratio of 15:1, and the mixed acidic wastewater is pumped into the 2# aeration sedimentation tank 2, and the content of each component in the mixed wastewater is Cu 2+ =400mg / L, Fe=3.2g / L, Al=0.3g / L, Cond=6000μs / cm, SO 4 2- =4000mg / L; Add the combination of sodium hydroxide c and calcium hydroxide d to 2# aeration sedimentation tank 2, control the dosage of sodium hydroxide c to 6.5kg / ton, and the dosage of calcium hydroxide d to 0.75 kg / ton, while introducing air through the rotation of the self-priming agitator 19 to realize aeration intensified neutralization reaction, control the reaction end point pH=3.8, and the reaction time is 25min, separate the aeration supernatant j and iron-containing precipitate k, Pump the iron-containing precipitate k to dense 6# treatment to obtain dehydrated iron-containing neutralized slag l and supernatant one m; add anionic flocculant at 10mg / L ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com