Low-temperature reduction smelting method for lead-containing compound

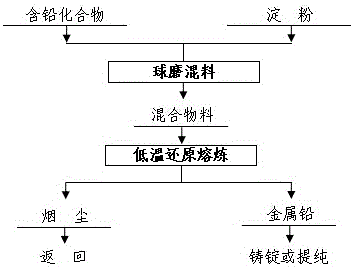

A compound and low-temperature technology, applied in the field of pyrometallurgy of low-temperature reduction and smelting of lead-containing compounds, can solve problems such as environmental pollution and increase difficulty, and achieve the effects of reducing energy consumption, low labor intensity and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The main components of lead-containing compounds are (%) by weight: Pb75.0% and H 2 O3.0%, the starch used is wheat starch. Add 2000g of lead compound and 180g of wheat starch into the ball mill, control the ratio of ball to material (the ratio of the weight of stainless steel balls to the weight of lead compound in Kg) to 1.0:1, add stainless steel balls with a diameter of 5mm, start the ball mill, and keep the rotation speed at 90r / min ball milling for 60 min. After the ball milling, the mixture is added to the smelting pot. The temperature of the smelting pot is maintained at 810 ℃ by the external heating method of burning coal. The stirring is started to keep the rotation speed at 120 r / min. The yield reached 96.8%.

Embodiment 2

[0030] The main components of lead-containing compounds are (%) by weight: Pb75.0% and H 2 O3.0%, the starch used is wheat starch. Add 2000g lead compound and 160g rice starch into the ball mill, control the ratio of ball to material (the ratio of stainless steel ball weight to lead compound weight Kg) to 1.0:1, add stainless steel balls with a diameter of 5mm, start the ball mill, and keep the rotation speed at 90r / min ball milling for 60 minutes, after the ball milling, the mixture is added to the smelting pot, the temperature of the smelting pot is maintained at 815 ℃ by the external heating method of burning coal, the stirring is started to maintain the rotation speed at 120 r / min, and the weight of crude lead is 1460 g. The yield reached 97.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com