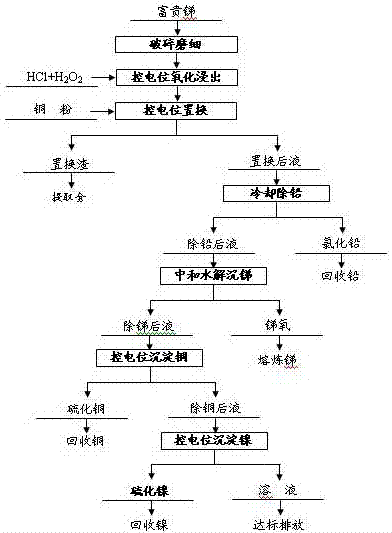

Method for potential-controlled separation and recovery of base metals in precious antimony

A base metal and potential technology, applied in the field of precious metal extraction metallurgical process, can solve the problems of silver dispersion recovery and poor separation effect, and achieve the effect of reducing reagent consumption, low production cost and good metal separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The main components of rich antimony are (%) by weight: Au1.5, Sb28.4, Cu34.8, Ni12.6, Pb13.7 and Ag0.6. Hydrochloric acid, hydrogen peroxide, sodium hydroxide and sodium sulfide are all industrial grade reagents, the mass percentage concentration of hydrochloric acid is not less than 36.0%, the mass percentage concentration of hydrogen peroxide is not less than 27.5%, and the mass percentage concentration of sodium hydroxide Not less than 96%, and the mass percentage of sodium sulfide is not less than 60%. The mass percentage of copper in the electrolytic copper powder is 99.8%, the particle size is -300 mesh and the bulk density is 2.2g / cm 3 .

[0040] Fugui antimony is crushed and ground until 100% of the powder passes through a 250-mesh sieve, and added to the hydrochloric acid solution with a concentration of 6.0mol / L according to the liquid-solid ratio (ratio of liquid volume L to solid mass Kg) L / S=11:1, and then heated When the temperature reaches 80°C, add hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com