Method for preparing octadecyl amine polyoxyethylene ether

A technology of aliphatic amine polyoxyethylene ether and aliphatic amine, which is applied in the field of preparation of octadecane fatty amine polyoxyethylene ether, can solve the problems of incomplete and thorough reaction, small polymerization reaction space, and great influence of polymerization reaction, etc., and achieve the product Good chemical stability, shortened reaction time, and thorough polymerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

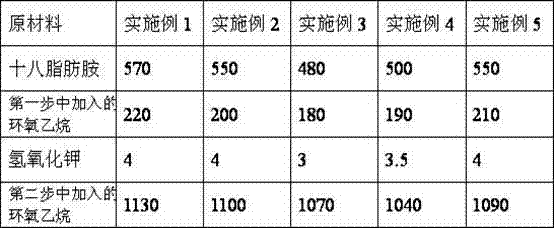

Embodiment 1

[0021] In the first step, add 570kg of octadecyl fatty amine into the 2000L spray reactor, heat up to 170°C while vacuuming, and the pressure in the kettle is 0.3MPa. The spray nozzle on the upper part of the kettle is sprayed into the kettle, and ethylene oxide is sprayed into the kettle at the same time, and the cycle is like this. The reaction is 1.5 hours, and the amount of ethylene oxide added is 220 kg. After the reaction, keep warm for 30 minutes and cool to 95 ° C.

[0022] In the second step, the inside of the above-mentioned kettle is evacuated to inhale 4 kg of catalyst potassium hydroxide, and the temperature is raised to 125 ° C, and the temperature is kept for more than 30 minutes. It is sucked out from the suction port at the lower part of the reactor, and then sprayed into the reactor from the spray nozzle at the upper part of the reactor, and ethylene oxide is added by spraying at the same time, and this cycle is repeated. The amount of ethylene oxide added is ...

Embodiment 2

[0026] In the first step, add 550 kg of octadecyl fatty amine into the spray reactor, heat up to 165°C while vacuuming, and the pressure in the kettle is 0.25MPa. The upper spray nozzle is sprayed into the kettle, and ethylene oxide is added by spraying at the same time, and the cycle is like this. The reaction is 1.0 hours, and the amount of ethylene oxide added is 200 kg. After the reaction, keep warm for 35 minutes and cool to 98 ° C.

[0027] In the second step, the inside of the kettle is evacuated to inhale 4 kg of catalyst potassium hydroxide, and the temperature is raised to 115°C, and the temperature is kept for 38 minutes. The air in the kettle is replaced with nitrogen for three consecutive times and the air is removed. The suction port at the lower part of the reaction kettle is sucked out, and then sprayed into the kettle by the spray nozzle at the upper part of the reaction kettle, and ethylene oxide is added by spraying at the same time. Keep warm for 40 minutes...

Embodiment 3

[0029] In the first step, add 480kg of octadecyl fatty amine into the 2000L spray reactor, heat up to 160°C while vacuuming, and the pressure inside the kettle is 0.2MPa. The spray nozzle on the upper part of the kettle is sprayed into the kettle, and ethylene oxide is sprayed into the kettle at the same time, and the circulation is like this. The reaction is 0.8 hours, and the amount of ethylene oxide added is 180 kg. After the reaction, keep warm for 40 minutes and cool to 90 ° C.

[0030] In the second step, the inside of the kettle is evacuated to inhale 3kg of catalyst potassium hydroxide, and the temperature is raised to 100°C, and the temperature is kept for 60 minutes. The suction port at the lower part of the reaction kettle is sucked out, and then sprayed into the kettle by the spray nozzle at the upper part of the reaction kettle, and ethylene oxide is sprayed at the same time, and this cycle is repeated. The amount of ethylene oxide added is 1070 kg, and the reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com