Lead blowing-furnace oxygen-rich smelting process

A technology of lead blast furnace and blast furnace, which is applied in the field of oxygen-enriched smelting process of lead blast furnace, can solve the problems of waste, difficult breakthrough, large manpower and material resources, etc., and achieve the effect of increasing the processing capacity, increasing the processing capacity and improving the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

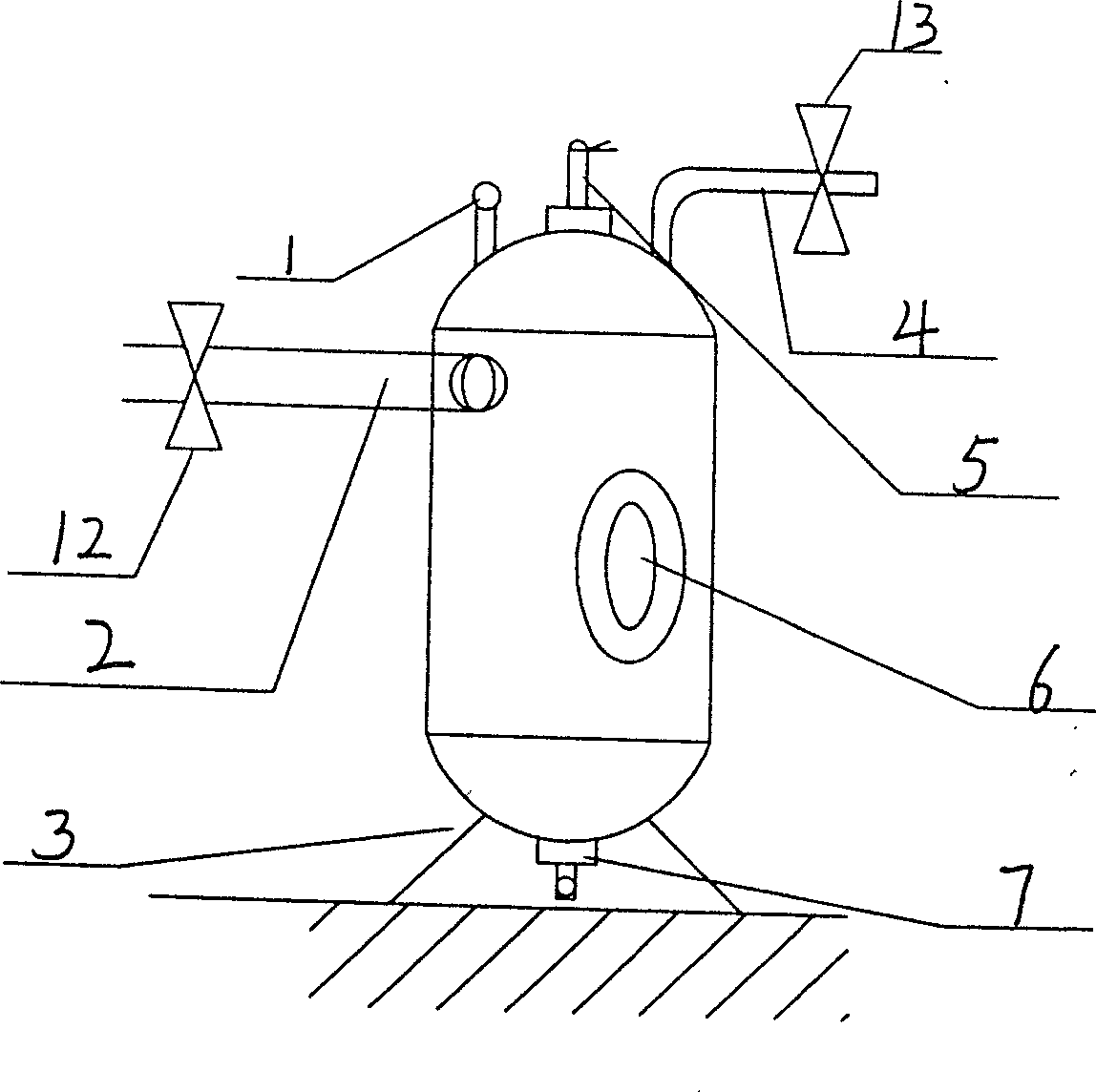

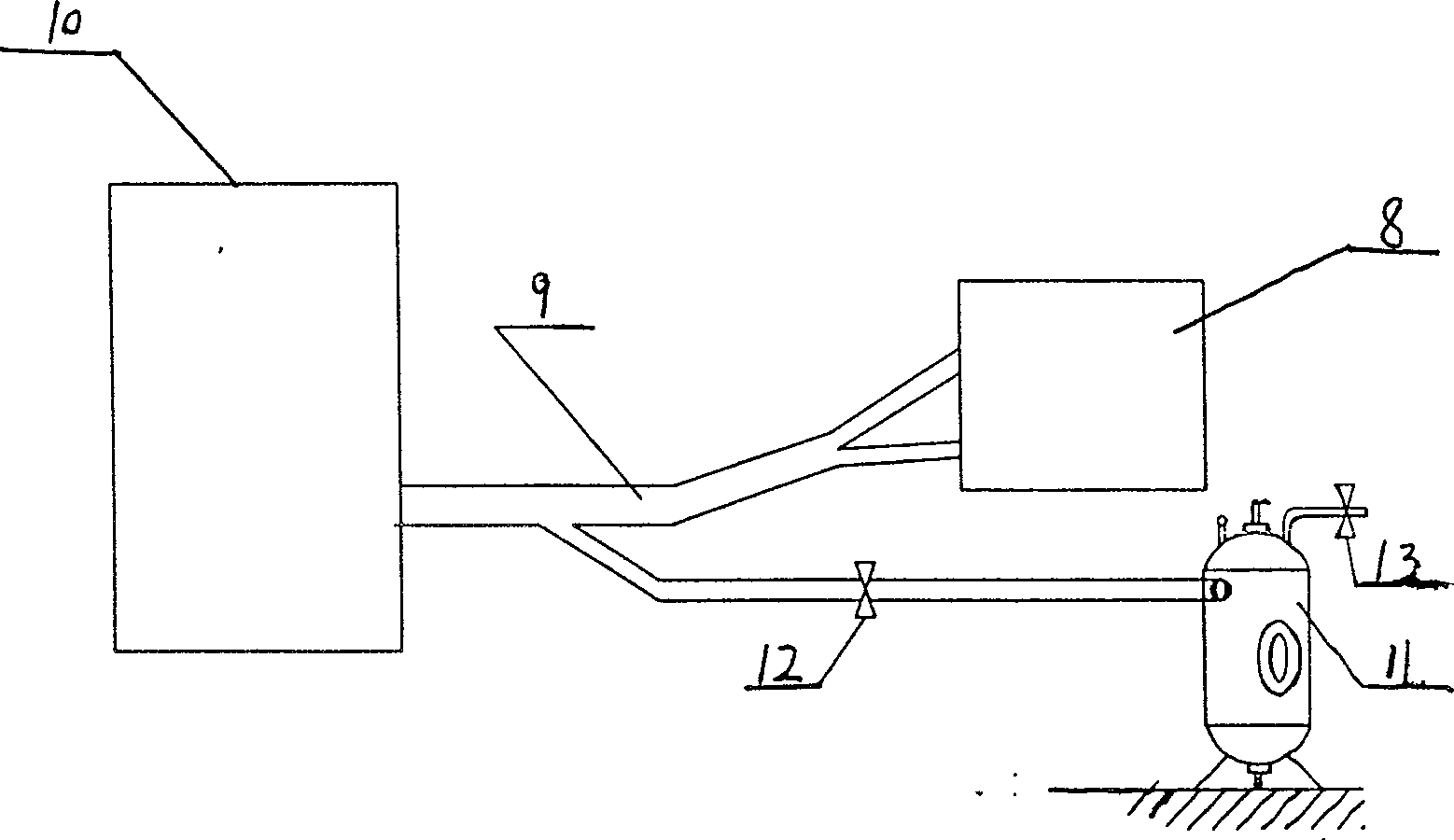

[0010] like figure 1 , 2 As shown, adding oxygen to the air supplied by the roots blower 8 to the blast furnace 10 increases the oxygen concentration in the air entering the furnace by 20-30%, thereby improving the reducing atmosphere of the furnace and increasing the processing capacity of the furnace. The method of adding oxygen to the air supplied by the Roots blower 8 to the blast furnace 10 is to connect an oxygen storage tank 11 through an oxygen pipeline on the pipeline for supplying air from the Roots blower 8 to the blast furnace 10, and the oxygen in the oxygen pipeline is connected with the Roots blower. The air supplied stably in the air is uniformly mixed in the air duct 9 and then sent to the blast furnace 10. Silicon brass oil-free valves 12 and 13 are arranged on the oxygen supply duct.

[0011] The oxygen storage tank 11 is connected to the oxygen plant where the oxygen is produced through the intake pipe 4. A pressure gauge 1 and a safety valve 5 are install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com