Red mud slurry heating method and apparatus for alumina production

A heating method, red mud slurry technology, applied in the field of red mud slurry heating, can solve the problems of low heating efficiency, influence on sedimentation separation and washing, uneven temperature of red mud slurry, etc., and achieve easy cleaning, easy scarring and clogging, cleaning difficult effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

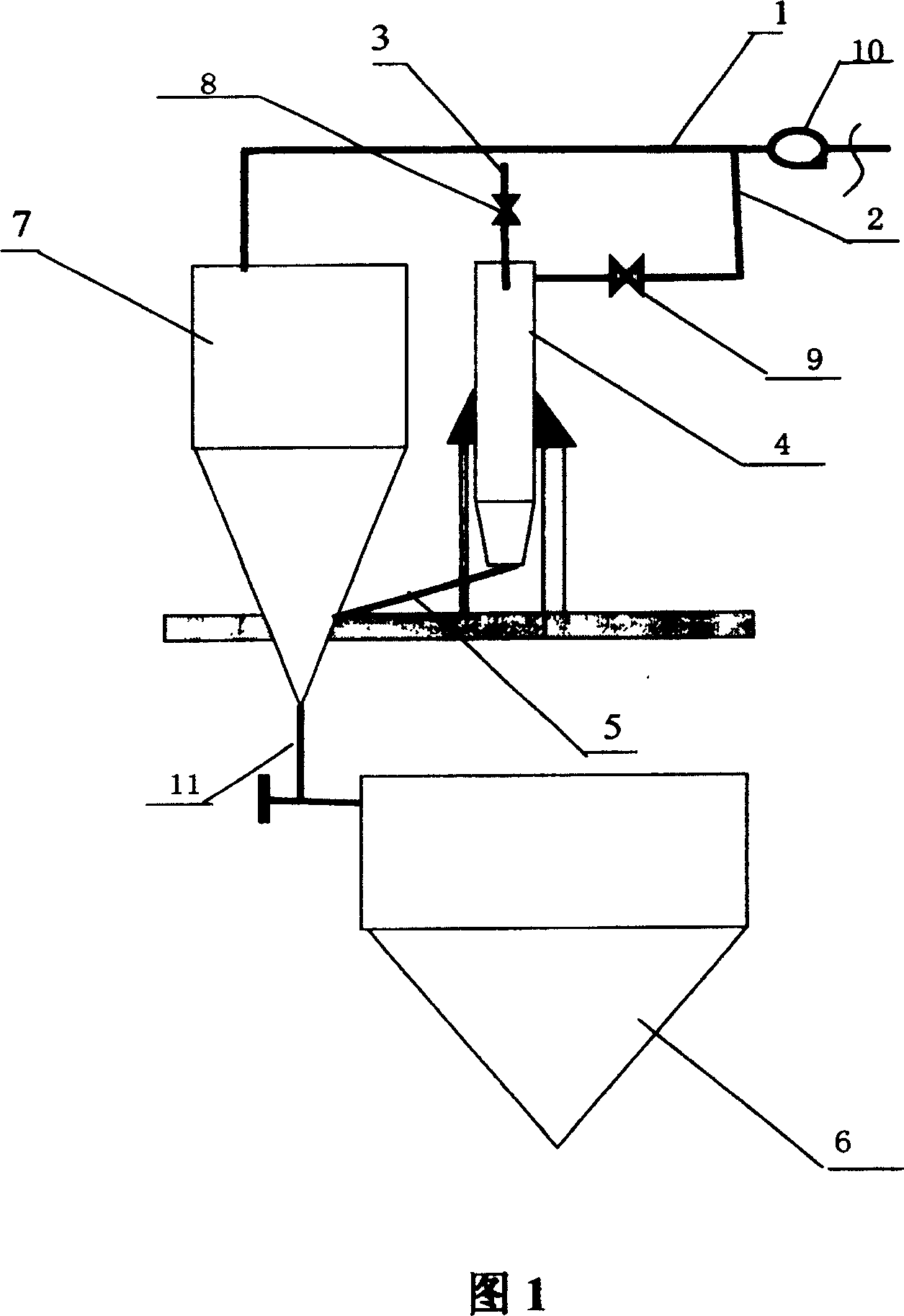

[0018] Embodiment of the present invention: due to heat dissipation and cooling in the process of material transportation and residence, the temperature of the red mud slurry from the previous process cannot meet the technical requirements of the sedimentation separation and washing process. Therefore, a branch pipe (2) is opened on the red mud slurry conveying pipeline (1) to divert the red mud slurry entering the feed tank (7), and 1 / 3 to 1 / 2 of the slurry is sent into the feed tank (7) through the valve (9). Heater (4) is thoroughly mixed with steam entering through pipe (3). After uniform heating, the feed box (7) that enters the settling tank (6) through the pipeline (5) is mixed with the red mud slurry that directly enters the feed box (7) through the pipeline (1), and then enters the settling tank through the pipeline (11) (6) To ensure that the red mud slurry reaches the slurry temperature required by the process technology during the washing process. The red mud slur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com