Patents

Literature

73results about How to "Save compressed air" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

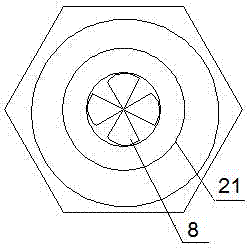

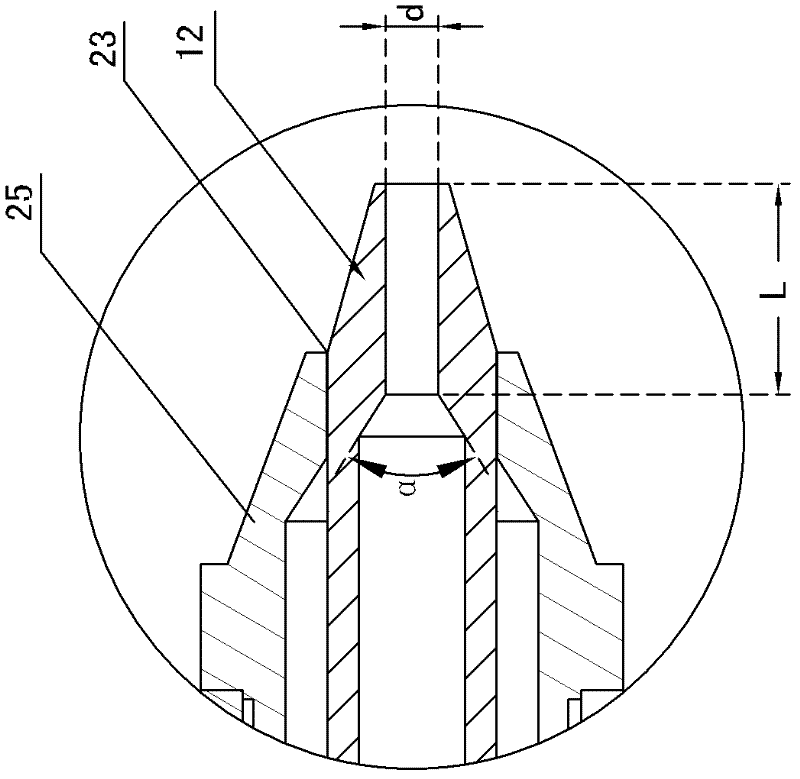

Inside-mixing atomizing nozzle device

InactiveCN103381398ARealization of centrifugal sievingImprove atomization effectLiquid spraying apparatusFiberDual effect

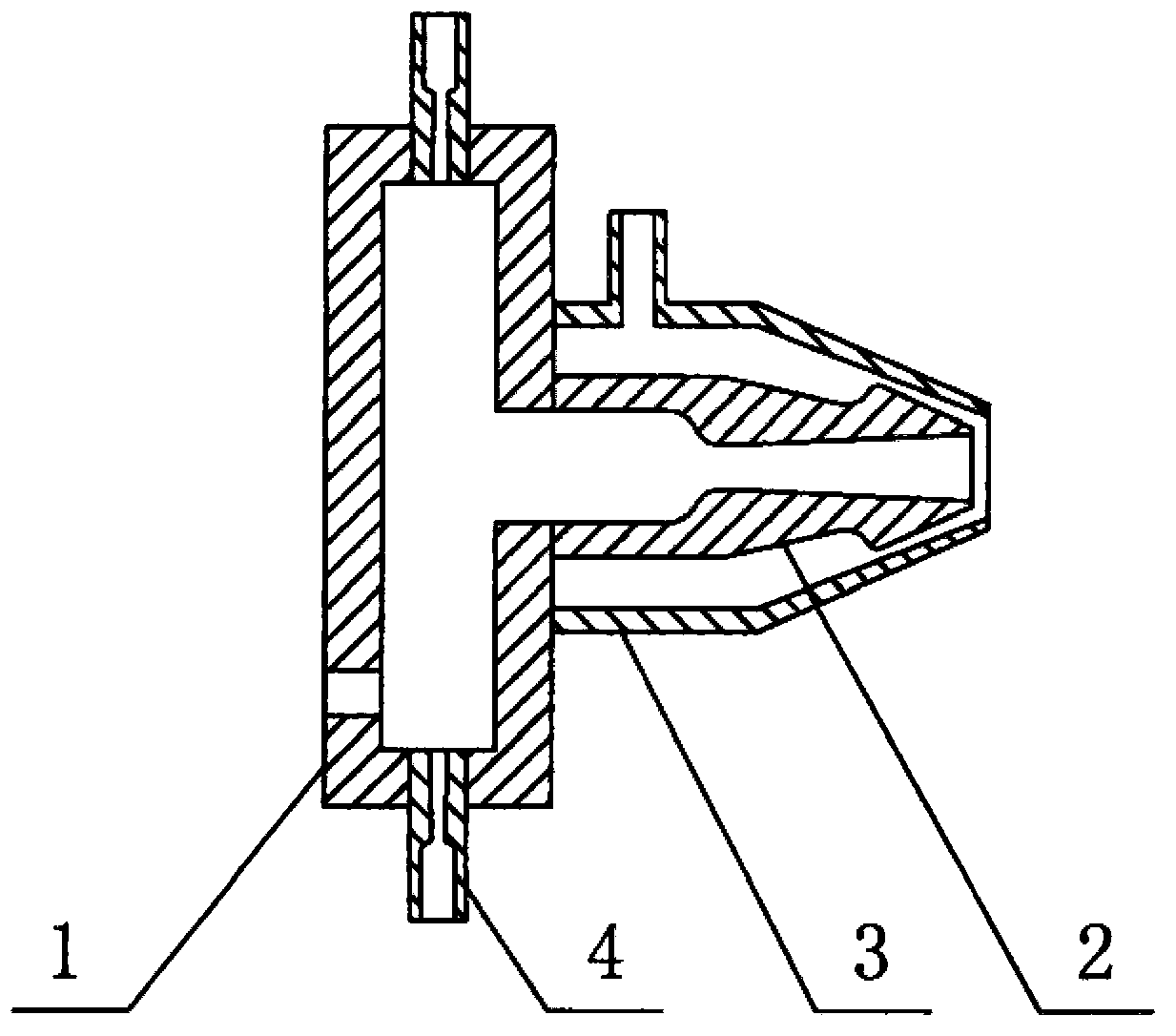

The invention provides an inside-mixing atomizing nozzle device. The nozzle device comprises a mixing cavity, the side wall of the mixing cavity is provided with an air inlet pipe, the outlet of the mixing cavity is provided with a spray pipe, and an airflow cover is sleeved outside the spray pipe. The inside-mixing atomizing nozzle device has the advantages of dual effects of airflow atomizing and airflow impacting, so that materials are blown away and atomized by high-speed airflow to form airflow mixed mist to rotate inside the cavity at a high speed and then impacted and collided by the high-speed airflow to be smashed into a mist shape; an ultrasonic airflow atomization function, so that the airflow atomization effect can effectively enhanced and compressed air can be saved; an outlet liquid drop atomizing function, so that air-material mixed mist can airflow-atomize condensation mass discharged along the wall again; simple structure, large material through holes and blocking-resistance. Besides, the inside-mixing atomizing nozzle device can well atomize fluid materials with poor fluidity, high solid content and high viscosity or even containing particle or fiber impurities.

Owner:星河航天科技(天津)有限公司

Air brake valve for locomotive

ActiveCN105383473ASimple structureSimple methodAerodynamic brakesApplication and release valvesControl valvesMode switching

The invention provides an air brake valve for a locomotive. The air brake valve comprises an operating valve which is connected with a train pipe air channel and an auxiliary air cylinder air channel; the operating valve is further connected with a first port of a two-way valve; the two-way valve is further provided with a second port and a two-way valve outlet; the second port is connected with an emergency pressure regulating valve through a two-position three-way reversing valve; the emergency pressure regulating valve communicates with a main air channel; a first control valve port communicating with the train pipe air channel is arranged at one end of the two-position three-way reversing valve; the two-way valve outlet is connected with a mode switching loop capable of communicating with a brake cylinder air channel. The air brake valve for the locomotive has output pressure regulation and selection functions, and is capable of solving the problems of simple and decentralized functions and high maintenance and repair costs of an existing air brake valve, and meeting the requirements of relief and different control pressure of a locomotive brake cylinder in service braking, emergency braking and dead-head mode braking states in an integration way.

Owner:CHINA ACADEMY OF RAILWAY SCI CORP LTD +3

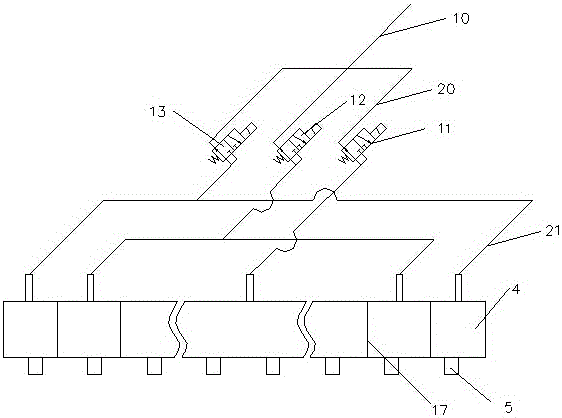

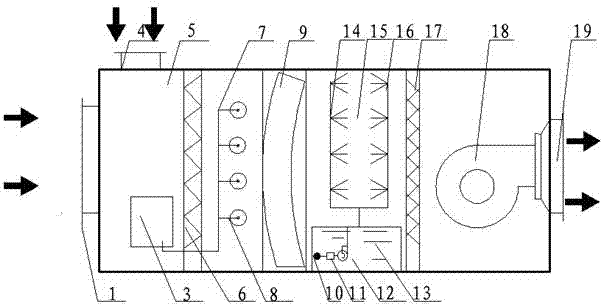

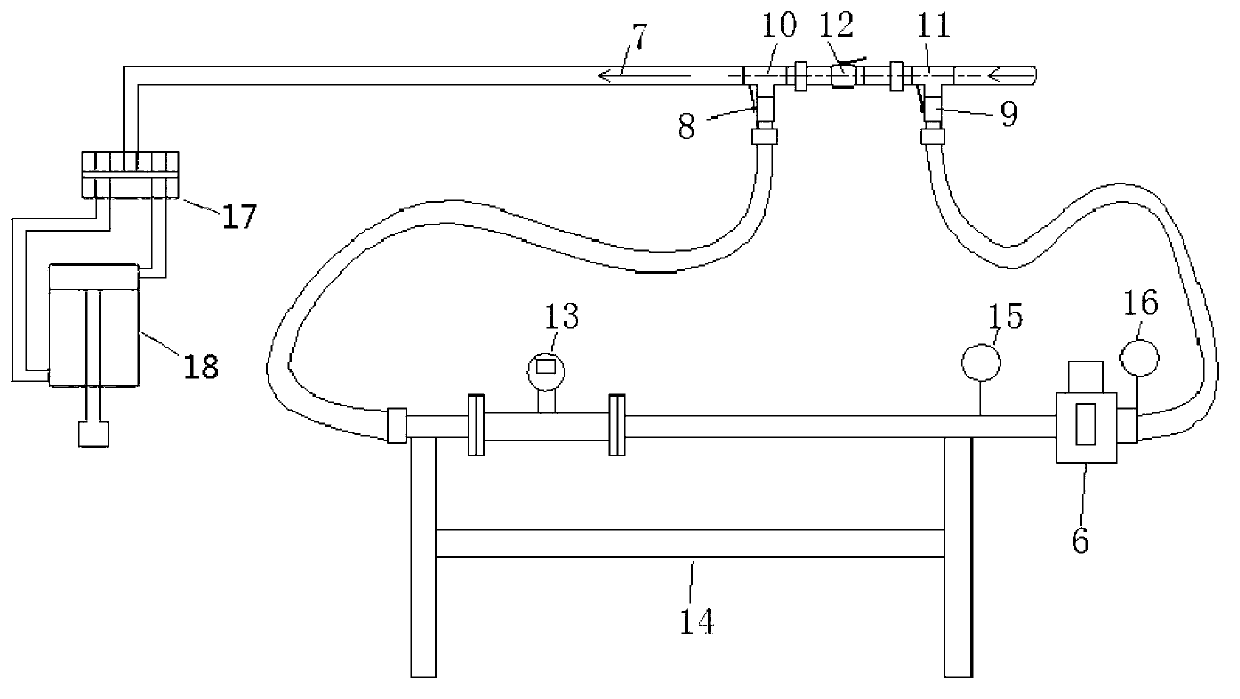

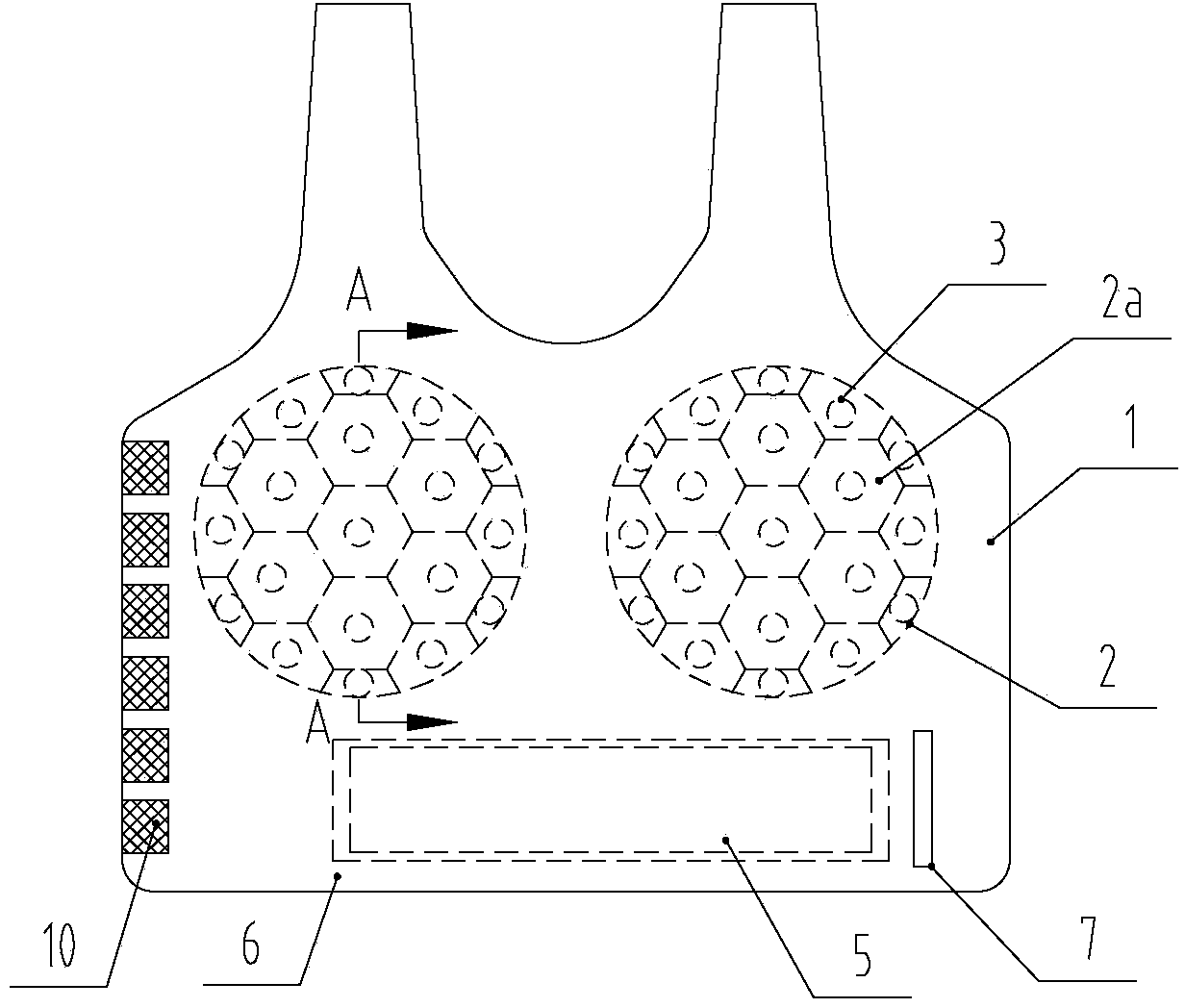

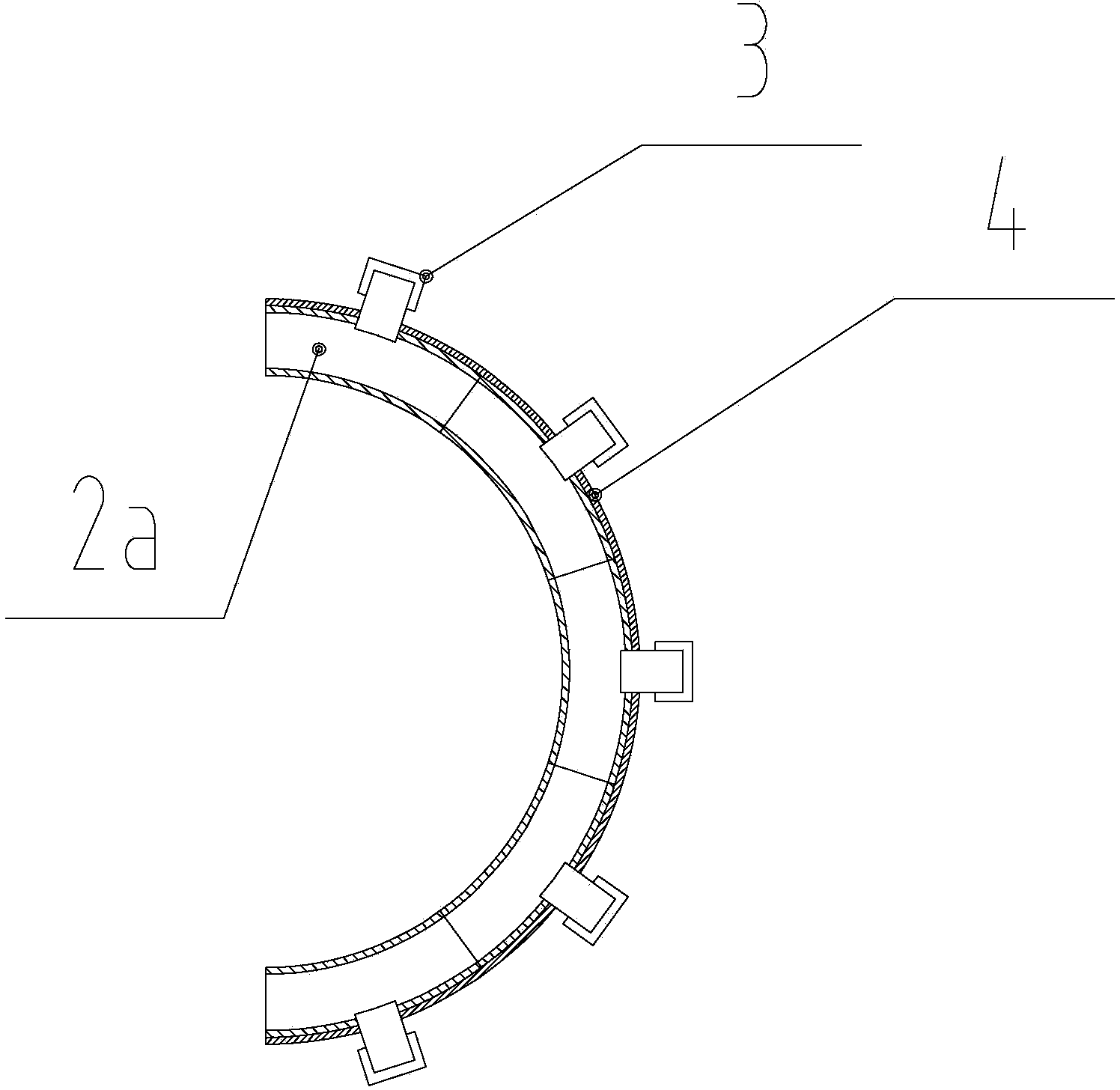

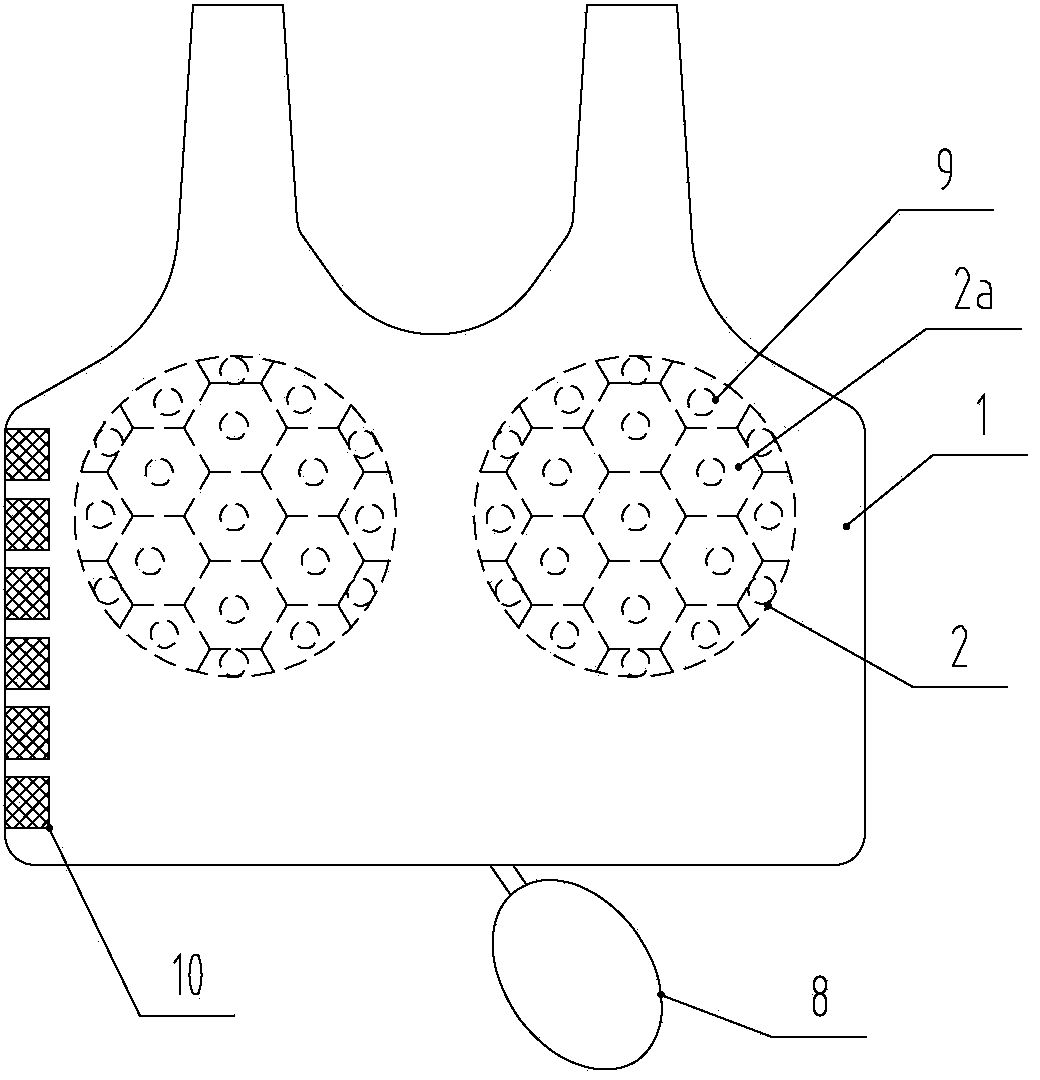

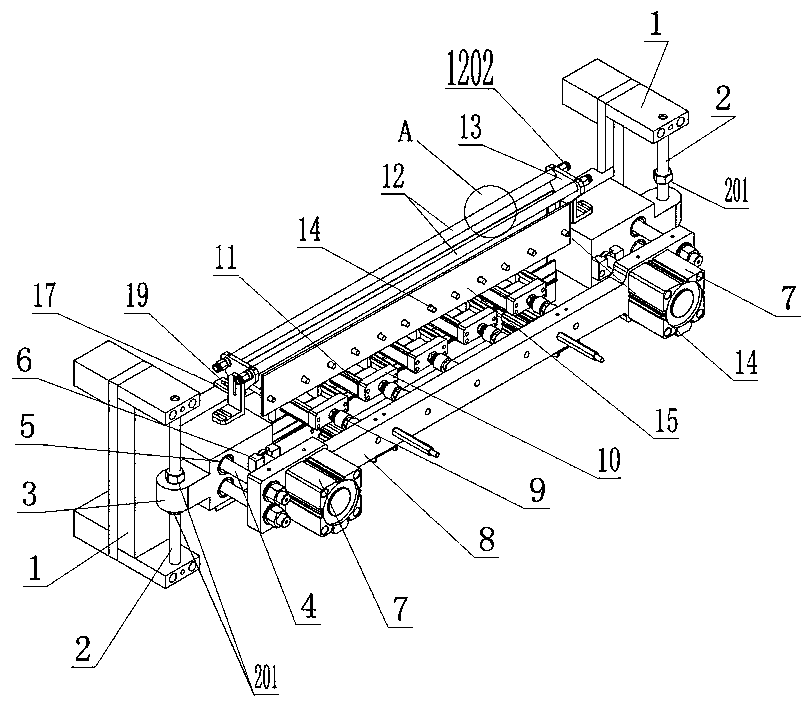

Mould-proof isolation powder pretreatment device and method for glass film plating production line

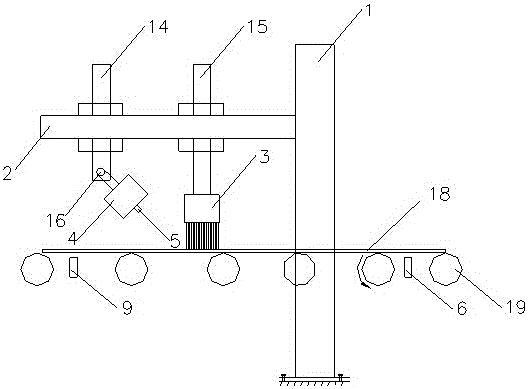

ActiveCN105057300AFlexible design of segment lengthFlexible designFlexible article cleaningCleaning using toolsProduction linePre treatment

The invention discloses a mould-proof isolation powder pretreatment device for a glass film plating production line. The device comprises a roller table and a main bracket, wherein the roller table is used for conveying glass; the advancing direction of the glass is from left to right; the main bracket is connected with a brush bracket and an air collecting pipe bracket in the transverse direction from right to left in sequence; the lower ends of the brush bracket and the air collecting pipe bracket are respectively connected with a brush and an air collecting pipe; the brush and the air collecting pipe are positioned above the glass on the roller table; a first sensor and a second sensor are arranged below the glass; the first sensor is positioned at the right side of the brush; and the second sensor is positioned at the left side of the air collecting pipe. Aiming at different glass widths, the part or all opening of an electromagnetic valve is controlled through glass width signals returned by the sensors, so that the jet airflow blows the glass surface with a smallest covering area to achieve the purpose of saving compressed air.

Owner:HENAN ANCAI HI-TECH +1

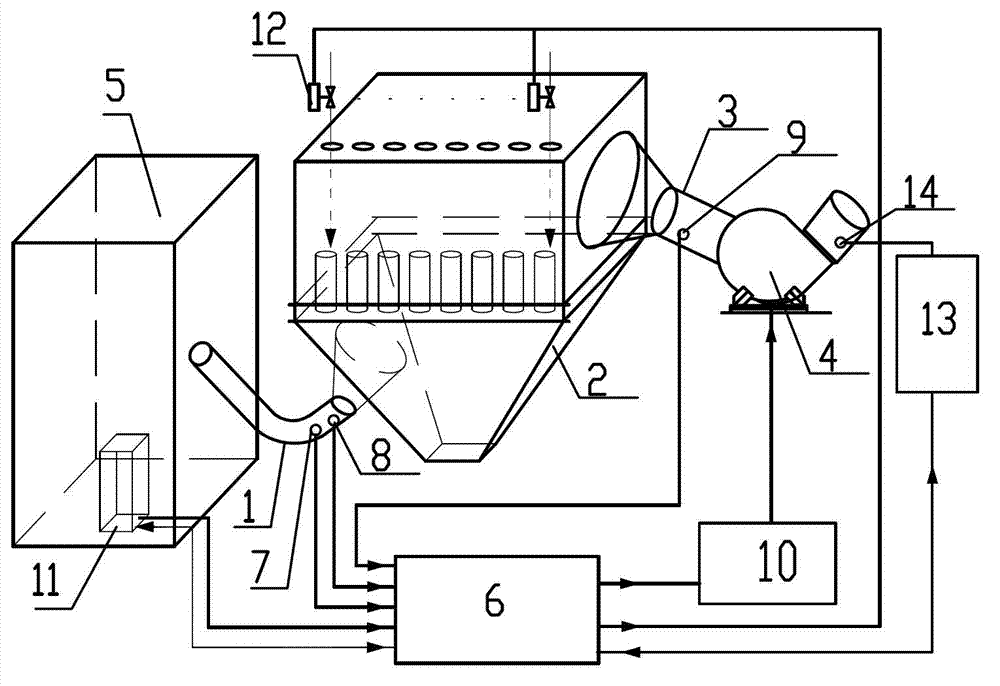

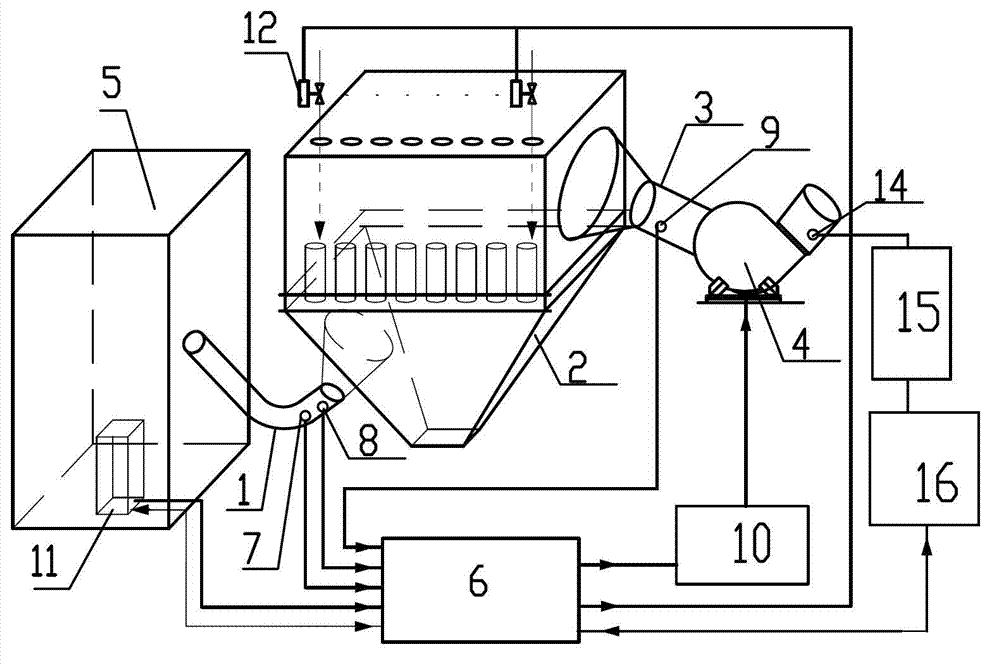

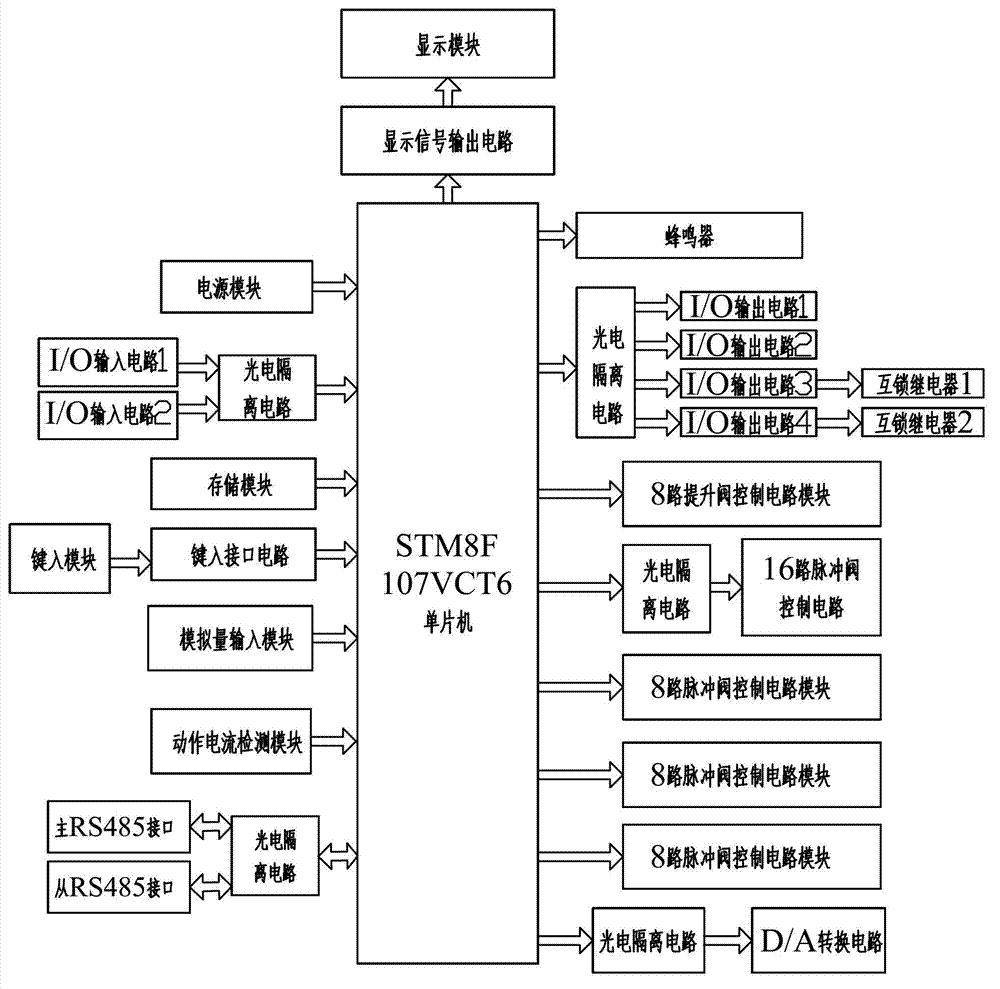

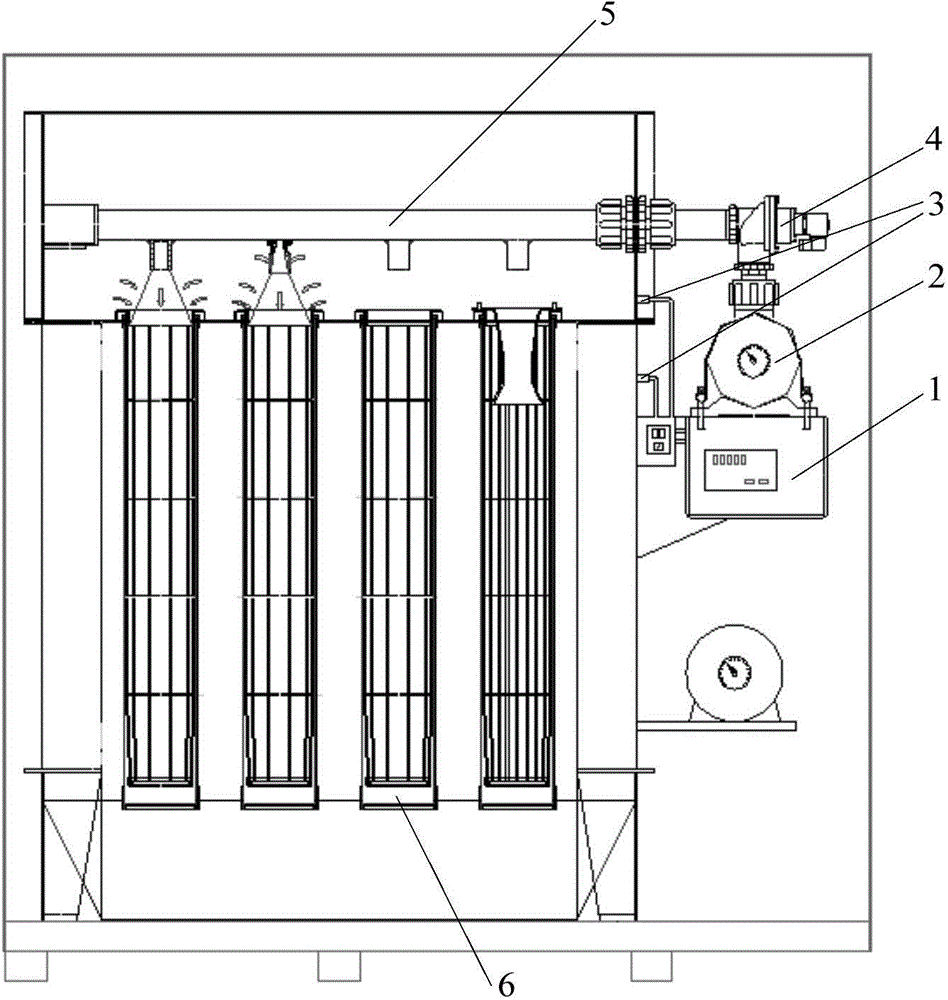

Dust removal system and controller thereof

InactiveCN102921247ALow running costImprove dust removal efficiencyDispersed particle filtrationControl modeSmart control

The invention discloses a dust removal system and a controller of the dust removal system. The dust removal system and the controller of the dust removal system detect the temperature and pressure of dust gas in a production process room at an inlet of a bag-type dust remover, and the pressure of the gas at an outlet of the bag-type dust remover, and the pressure or the temperature of the dust gas at the inlet or a work mode of a control system in the process of production is set as a set value to control a frequency converter to achieve control of the rotation speed of a draught fan. The controller can be connected with an online or off-line air purification detector to achieve closed-loop control of the air speed. The controller controls opening and closing of an impulse dust removal valve through differential pressure at the inlet and the outlet of the dust removal gas and the time of variation of the differential pressure, and achieves high-intelligent control modes of the bag-type dust removal, such as on line, off line, chamber division and cascade connection. The dust removal system and the controller of the dust removal system have the advantages of integration of dust removal series, modularization of the internal structure, diversification of functions, intelligentization of the control modes and optimization of cost performance, thereby being suitable for various occasions.

Owner:UNIV OF JINAN

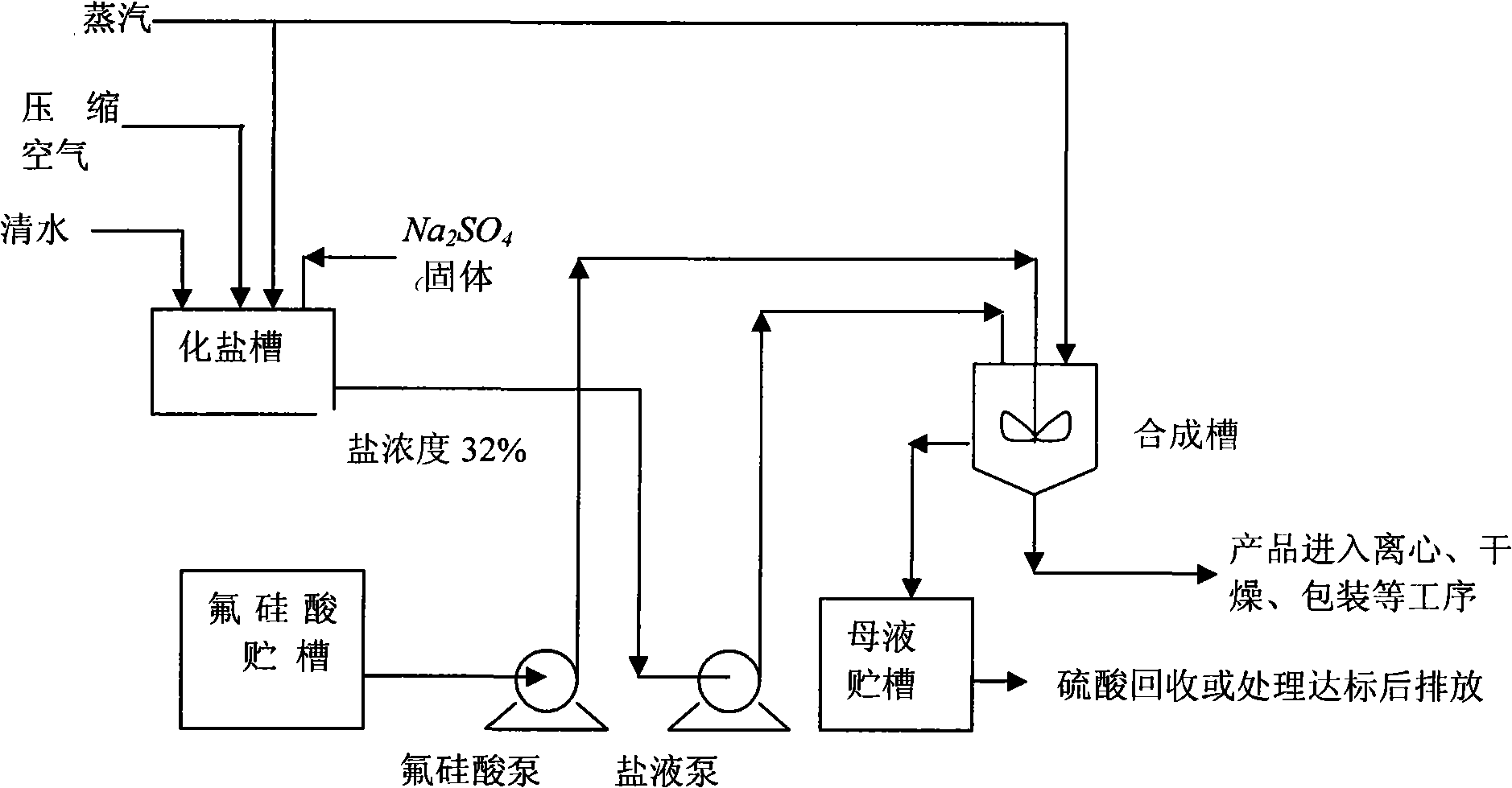

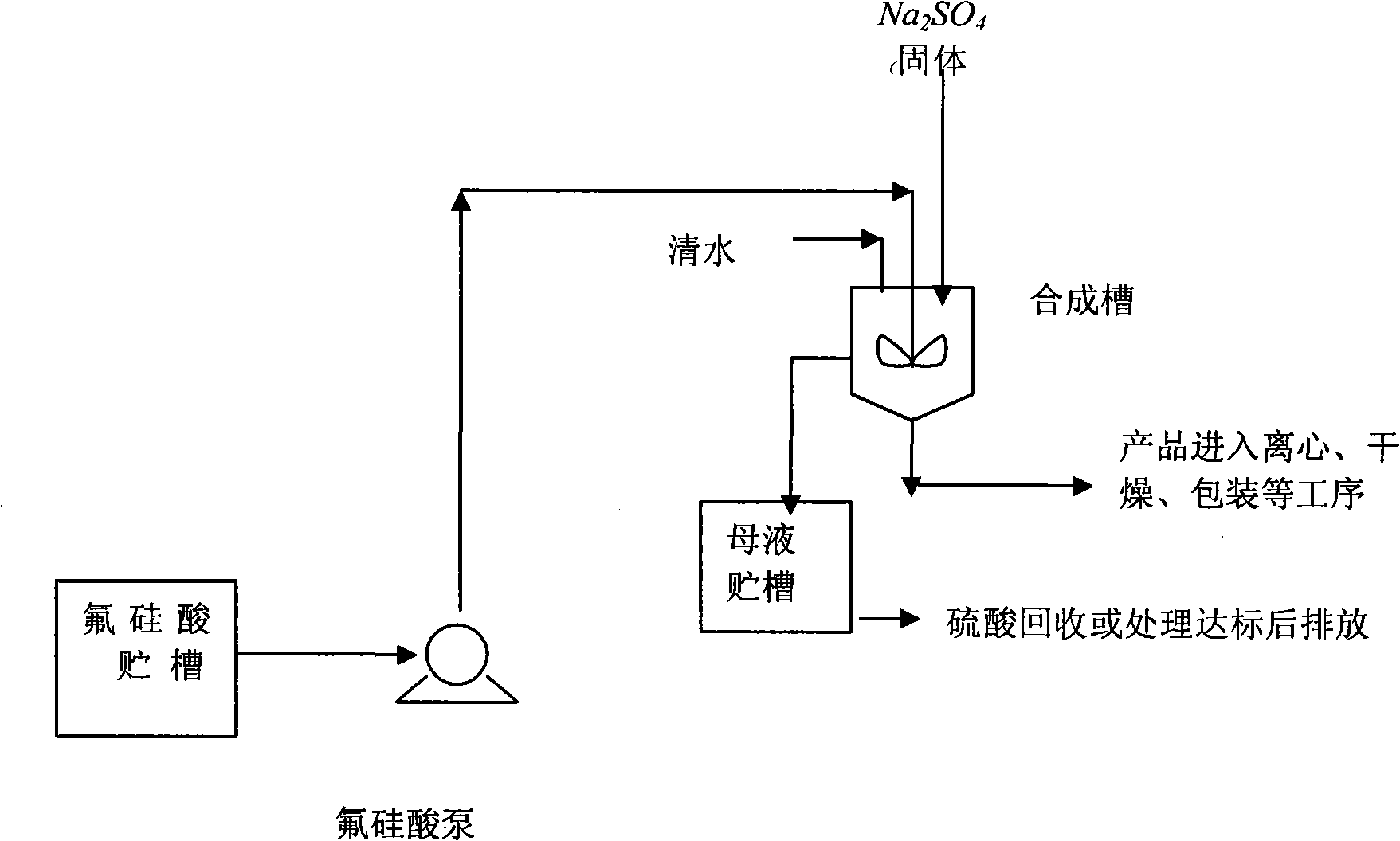

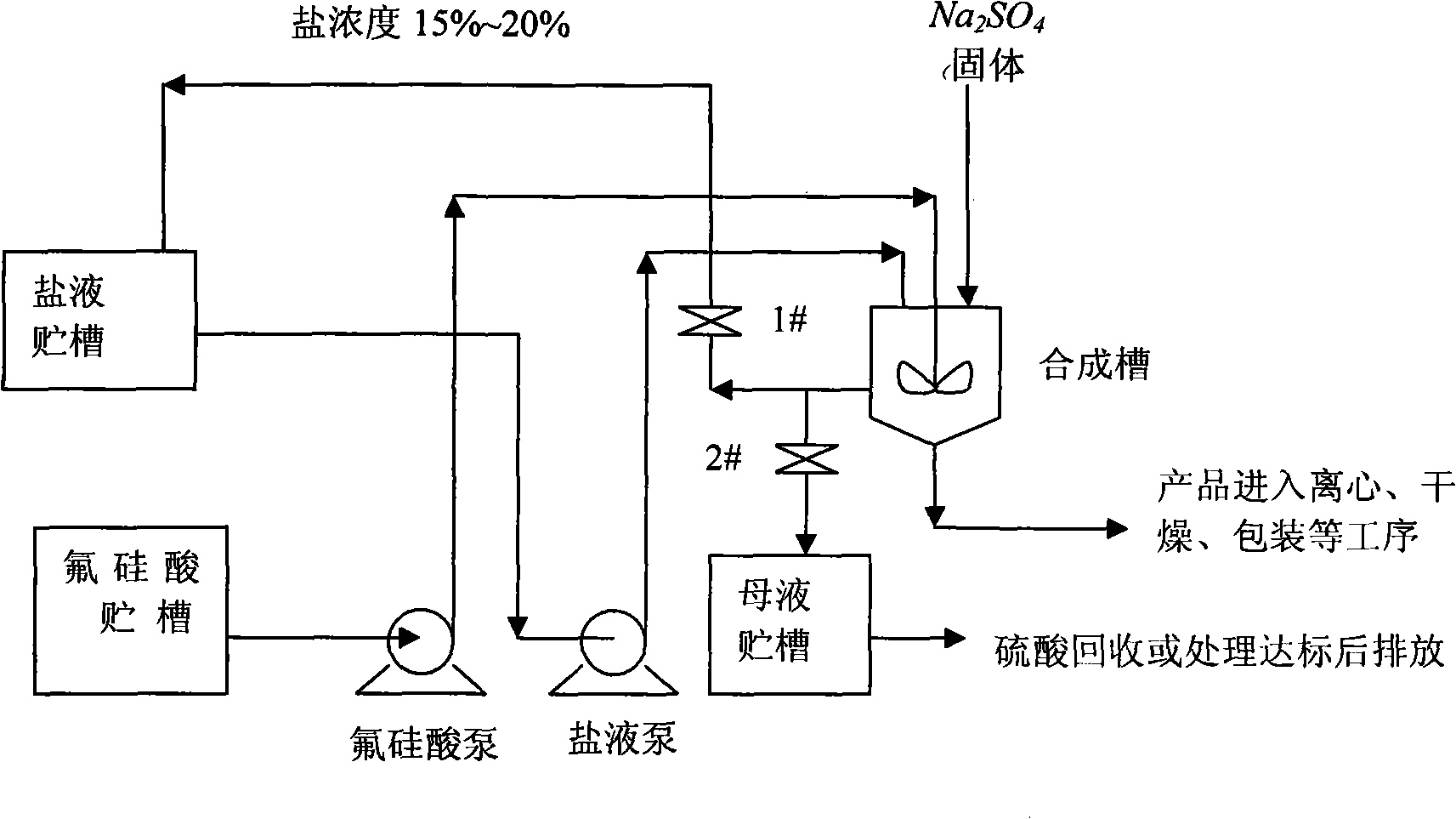

Preparation process of prodan by sodium sulfate method

InactiveCN101284669AHigh recycling valueSave compressed airAlkali metal silicatesChemistrySodium fluosilicate

The invention discloses a process for producing sodium fluosilicate by using sodium sulfate, which comprises the following steps: (1) subjecting the solution of hydrofluorosilicic acid and sodium sulfate with the mol ratio of 1:1.0 to 1.2 to reaction and crystallization; (2) adding solid sodium sulfate to the reaction solution for salt dissolution till the mass percent concentration of the sodium sulfate reaches 15 to 20%; (3) separating the sodium fluosilicate; (4) subjecting the mother solution slating liquid to a circulated process of salt dissolution and reaction. The method utilizes the water of the hydrofluorosilicic acid, saves a large part of water for the salt dissolution and reduces the production of sewage; the salt dissolution by the mother solution is to continue to add excess amount of salt so as to continue to enlarge the size of hydrofluorosilicic acid crystals and increase the precipitation quantity. The utilization rate of the hydrofluorosilicic acid can reach to above 96%, which is far higher than the level of around 80% by prior solution method.

Owner:NORTHWEST UNIV

High pressure air injection-fluid power type water spraying chamber composite evaporative cooling air-conditioning unit

InactiveCN102230651AIncrease jet expansion entrainmentIncrease expansion entrainmentLighting and heating apparatusEnergy industryCooling effectHigh pressure

The invention relates to a high pressure air injection-fluid power type water spraying chamber composite evaporative cooling air-conditioning unit which is characterized in that the side wall opposite to the shell of the unit is respectively provided with an air inlet and an air supply outlet; the shell of the unit is internally provided with a primarily efficient filter, a high pressure air injection cooling air device, a rotation type air flow equalization plate, a fluid power type water spraying device, a weir plate and an air feeder in turn in an air inlet direction; a novel air returningmixed section is arranged between the air inlet and the primarily efficient filter; and the side wall of the unit shell on the novel air returning mixed section is provided with an air returning port. According to the invention, high pressure air injection and fluid power type water spraying chambers are organically combined, and two direct evaporative cooling sections are used, thus the unit hasan obvious cooling effect on places in which indoor air needs to be cooled in quantity, such as industrial factory buildings and workshops based on high sensible heat, especially, mines.

Owner:XI'AN POLYTECHNIC UNIVERSITY

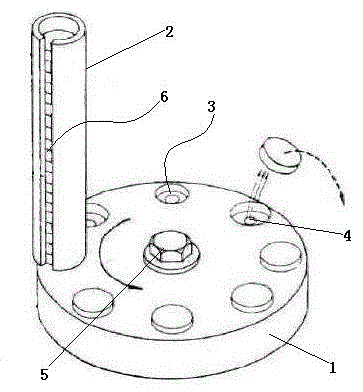

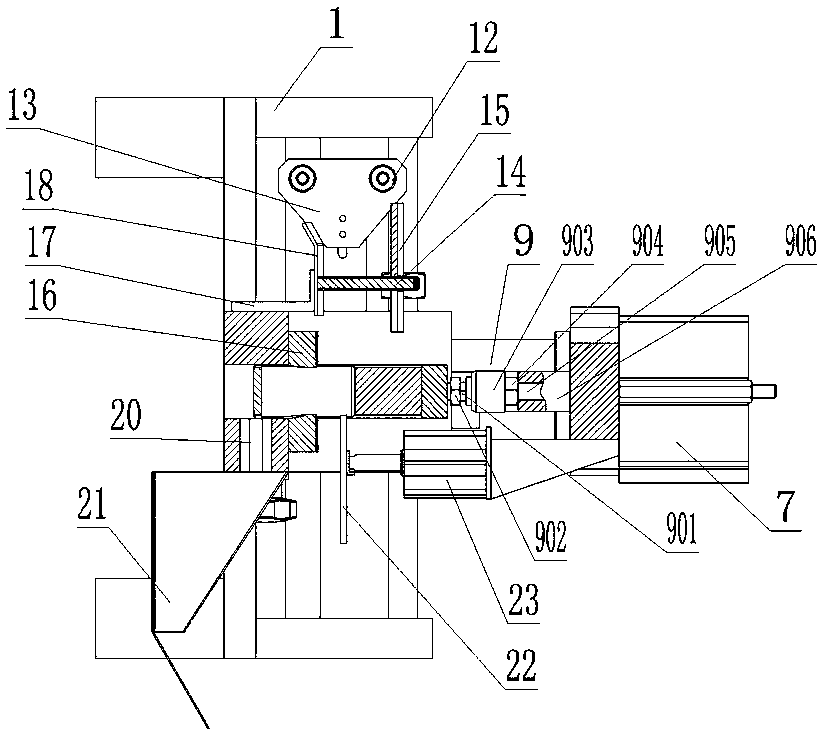

Oil-gas two-phase jet-type lubricating and cooling system

The invention discloses an oil-gas two-phase jet-type lubricating and cooling system, comprising a pressure gas supply device, a pressure oil supply device, a pure oil nozzle and N gas-oil nozzles, wherein the pressure gas supply device is connected with the gas-oil nozzles through an airflow pipeline; the pressure oil supply device is connected with both the pure oil nozzle and the gas-oil nozzles by an oil pipeline; each gas-oil nozzle comprises an oil jet pipe and an airflow jet pipe coaxially arranged outside the oil jet pipe; a shrinkage oil nozzle is arranged at the front end of the oil jet pipe; the gap between the internal wall of the airflow jet pipe and the external wall of the oil jet pipe forms an airflow passage; the front end of the airflow jet pipe is provided with an annular gas nozzle; oil-gas binary oil-in-gas concentric jet is formed by the continuous column oil jet sprayed from the shrinkage oil nozzle and the annular gas jet sprayed from the annular gas nozzle; the oil is not mixed with the gas; when the system is working, oil molecules on the surface of headed materials and the contact surface of mould and the headed materials have stronger permeability so as to lubricate and cool more sufficiently.

Owner:山东腾达紧固科技股份有限公司

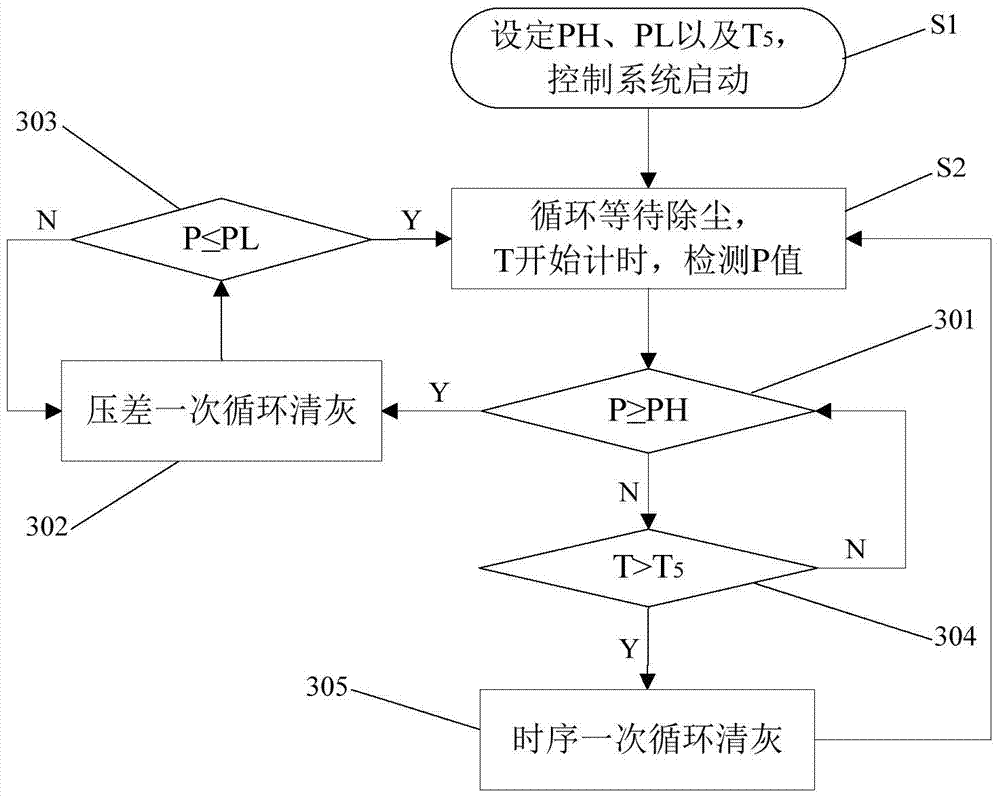

A pressure difference-timing sequence mixed control method for a bag type dust collector

InactiveCN105688531AReduce resistanceSave compressed airDispersed particle filtrationEngineeringLower limit

Owner:上海袋式除尘配件有限公司

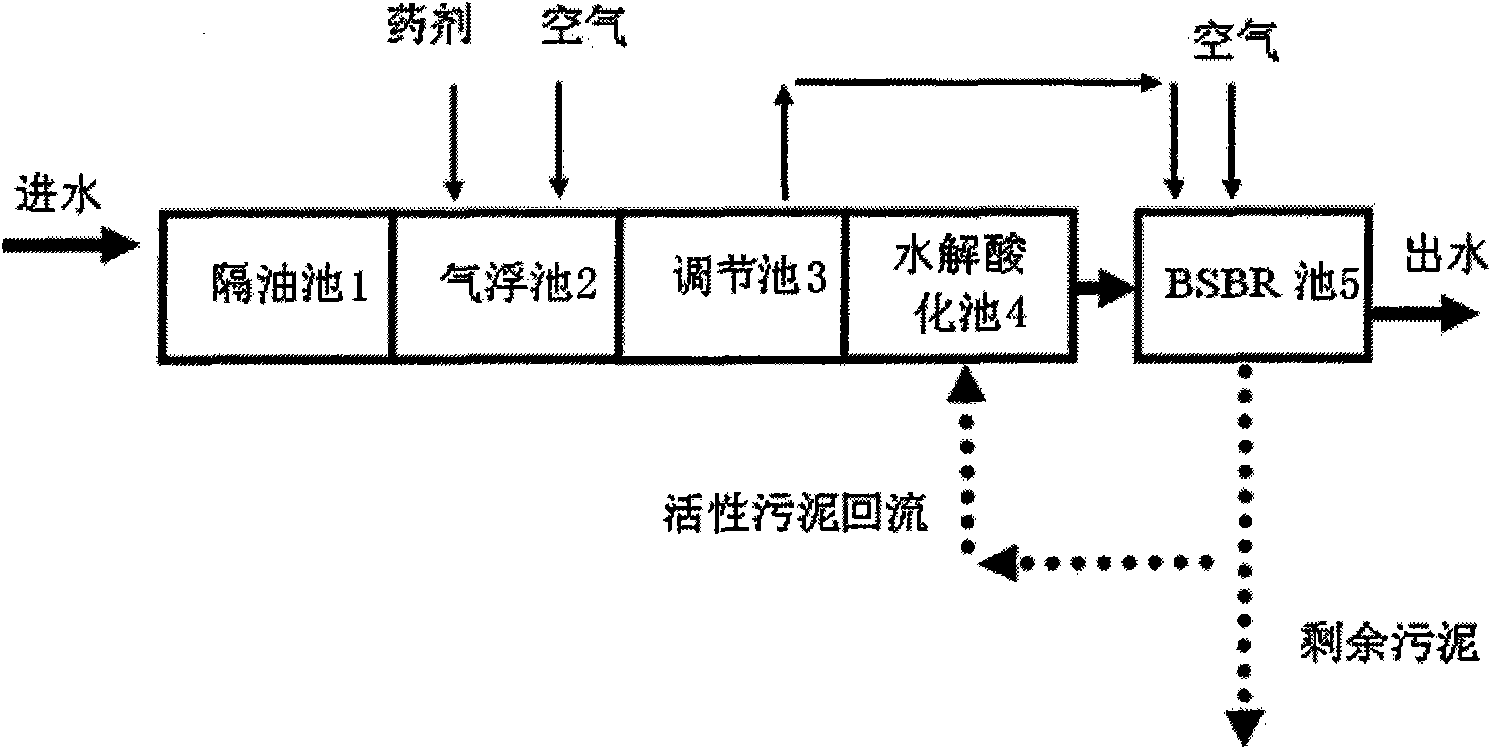

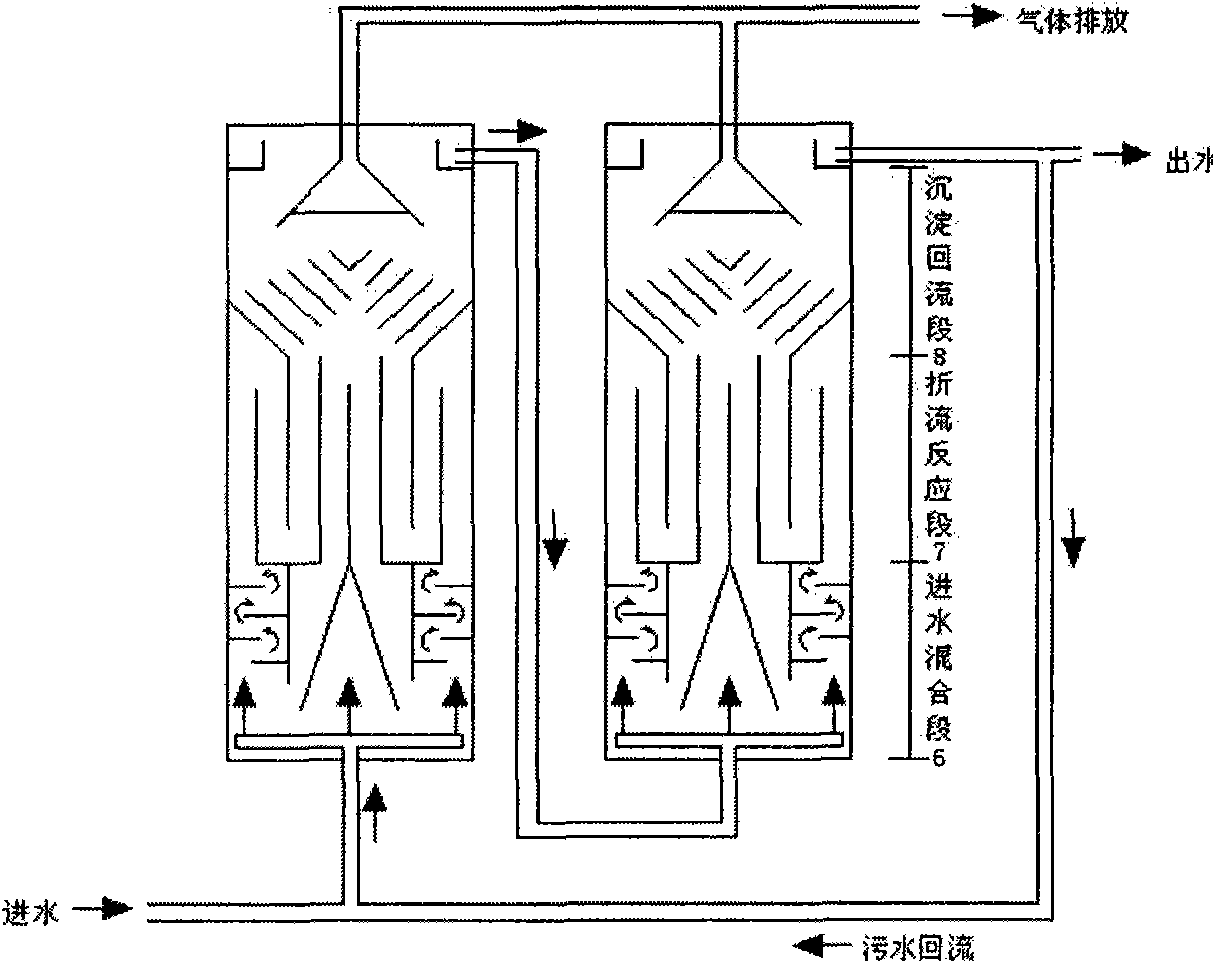

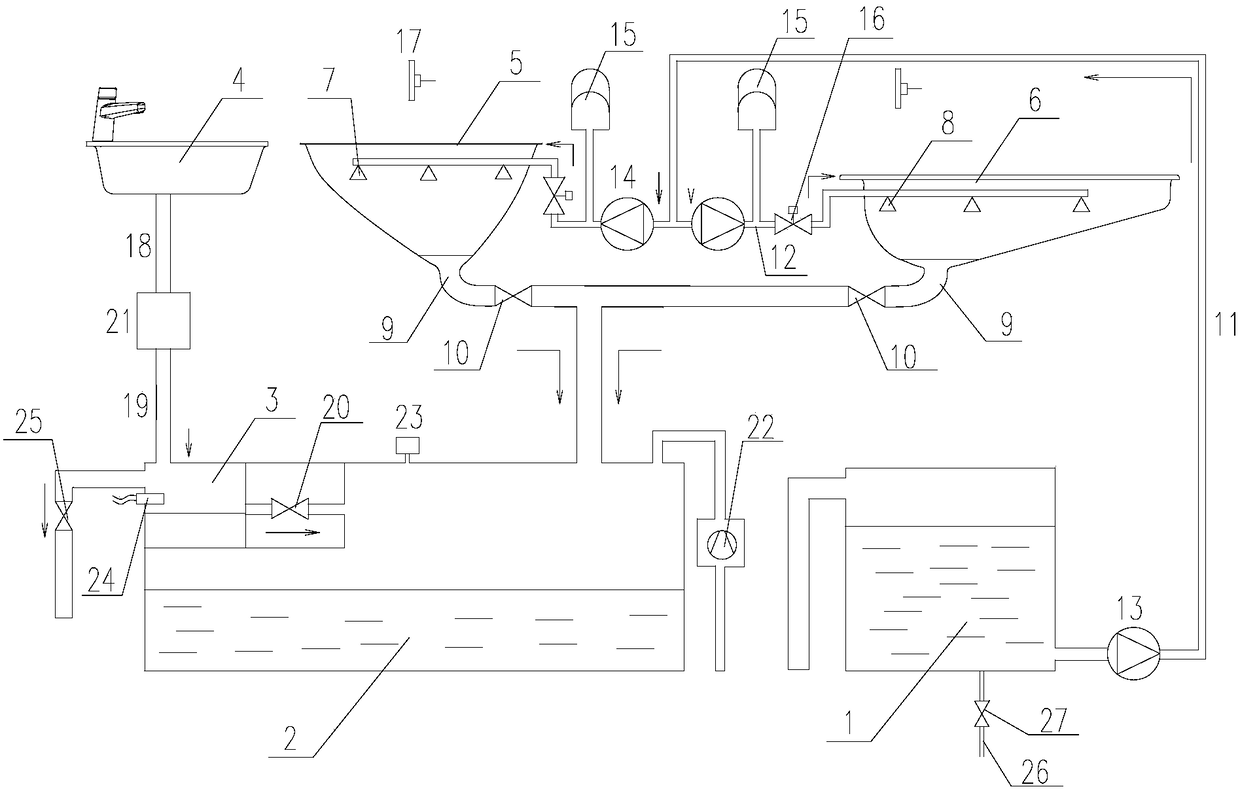

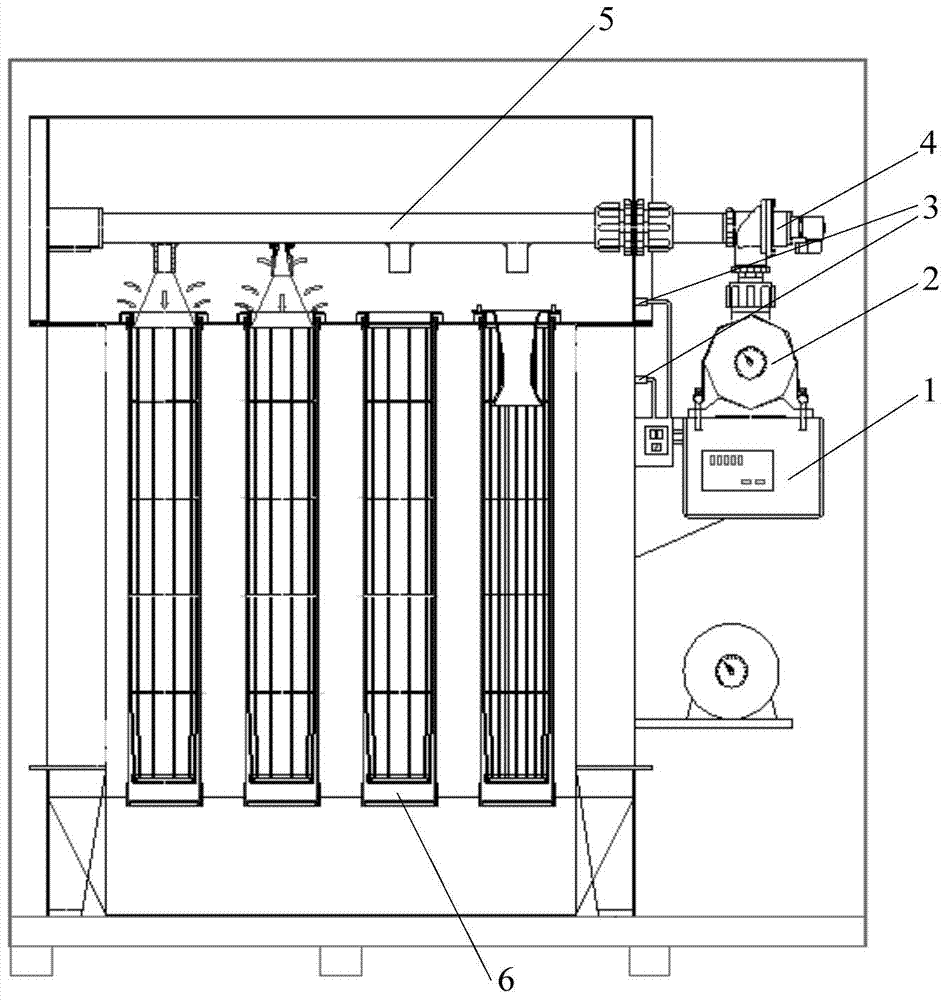

Coking wastewater treatment process and coking wastewater treatment equipment

InactiveCN101597127ASave compressed airReduce power consumptionFatty/oily/floating substances removal devicesTreatment with aerobic and anaerobic processesTarOrganic acid

The invention relates to a wastewater treatment process, in particular to a coking wastewater treatment process and coking wastewater treatment equipment. The process comprises the following steps: a, isolating oil floating on the surface of coking wastewater through horizontal flow; b, removing emulsive tar oil and part of COD and BOD5 in the coking wastewater by using a pressure dissolved-air flotation; c, balancing water quality and quantity of the treated coking wastewater; d, converting refractory polyaromatic hydrocarbons and heterocyclic compounds in the wastewater into simple low molecular organic acid compounds; e, retaining sludge and reflowing the wastewater; f, performing biological degradation of the organic matters in the wastewater and the removal of nitrogen and phosphorus from the wastewater and treating the wastewater by using a BSBR method; and g, finally, recovering the treated water. The process has the advantages of energy and space conservation, excellent wastewater treatment effect and the like.

Owner:UNIVERSTAR SCI & TECH SHENZHEN

Automatic adjustable dragging method pipe

InactiveCN101462645ASmooth circulationMinimize the effect of stationarityOperating means/releasing devices for valvesBulk conveyorsSection planeAtmospheric pressure

The invention relates to an automatic adjustable laval pipe, which can automatically change the pipe diameter of the laval pipe, realize adjustment of the required air quantity according to the characteristics of materials, provide stable air flow under the condition of air pressure fluctuation, and is suitable for a material conveying system which requires regular adjustment of the air quantity. The automatic adjustable laval pipe mainly comprises an air inlet pipe, a regulating stem and a fixed laval pipe, wherein the air inlet pipe and the fixed laval pipe are fixedly connected with each other; the regulating stem runs through the air inlet pipe; the outer end part of the regulating stem is connected with an automatic pressure regulator, and the inner end part of the regulating stem is extended into an inlet of the fixed laval pipe; a cross section of the inlet is provided with a funnel-shaped curved structure; a first section of curve is a section of circular arc of which the circle center is on an inlet interface of the fixed laval pipe; a third section of curve is a section of circular arc of which the circle center is on a minimum cross section on a throat section of the fixed laval pipe; and a second section of curve is a common tangent line which connects the first section of curve and the third section of curve.

Owner:MESNAC

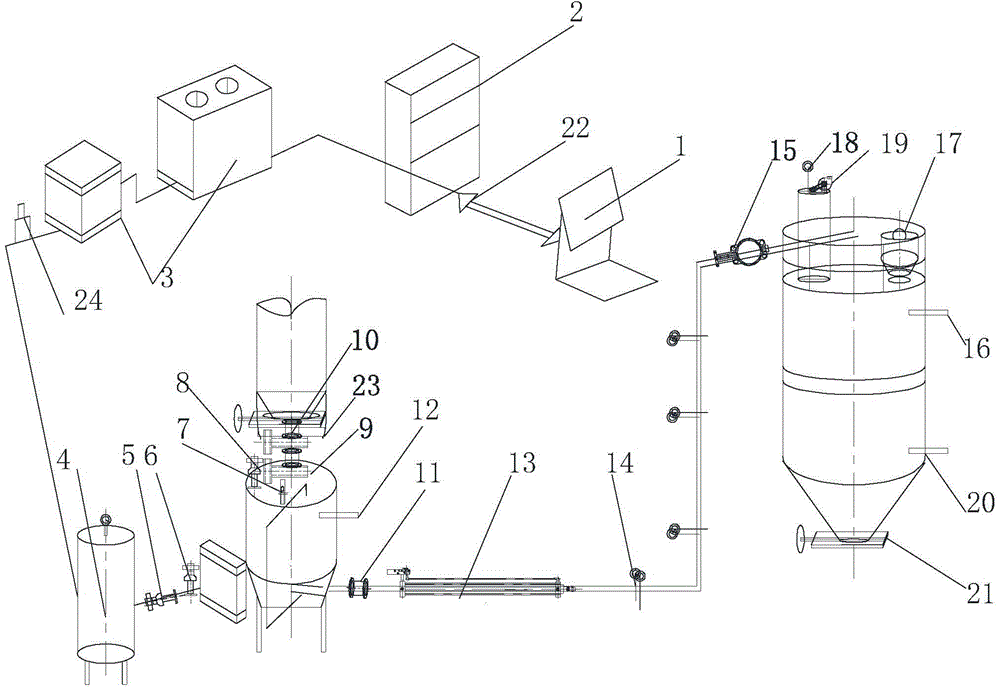

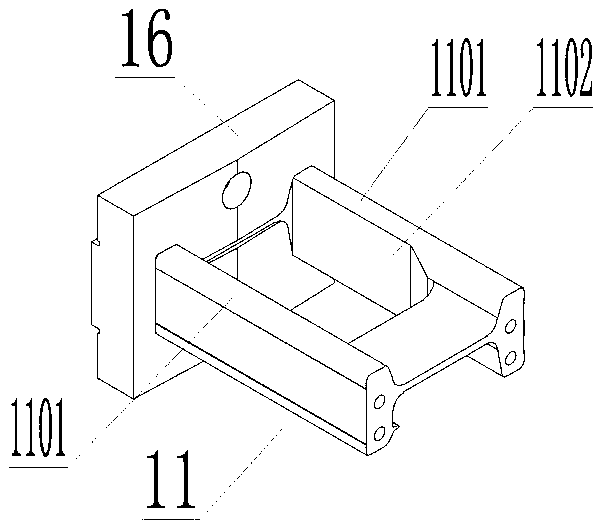

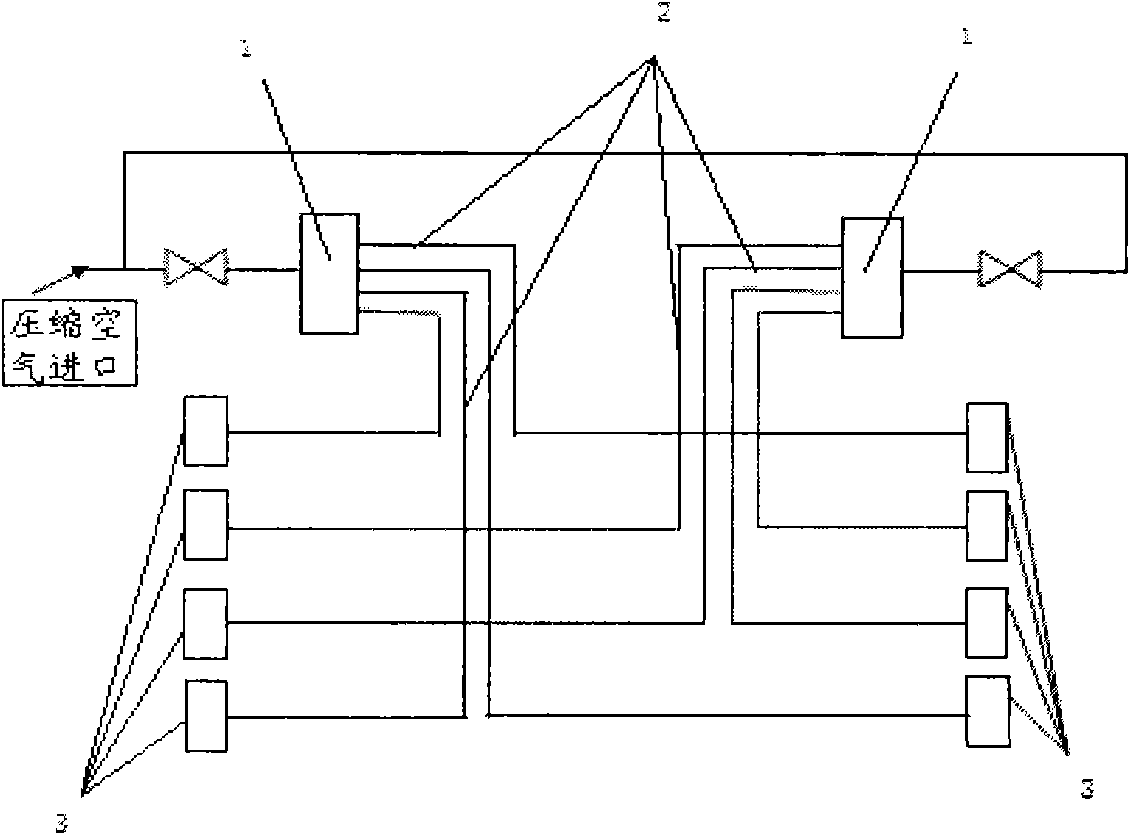

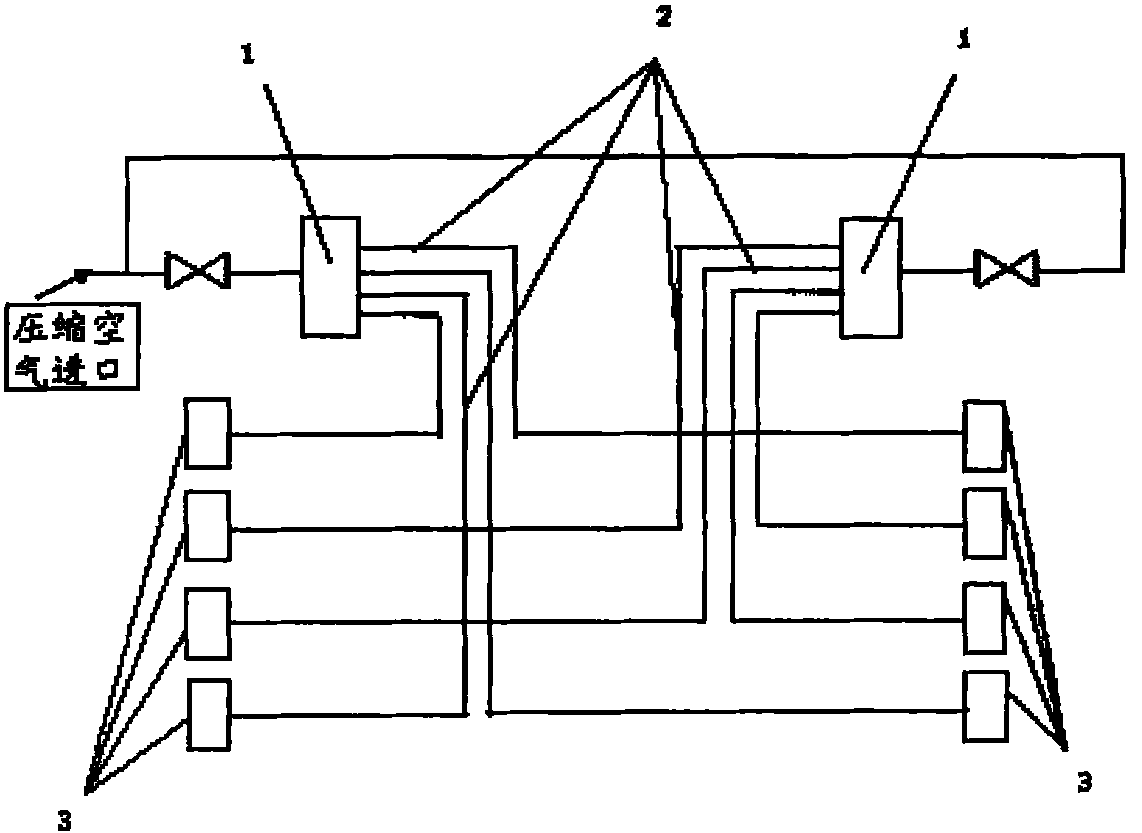

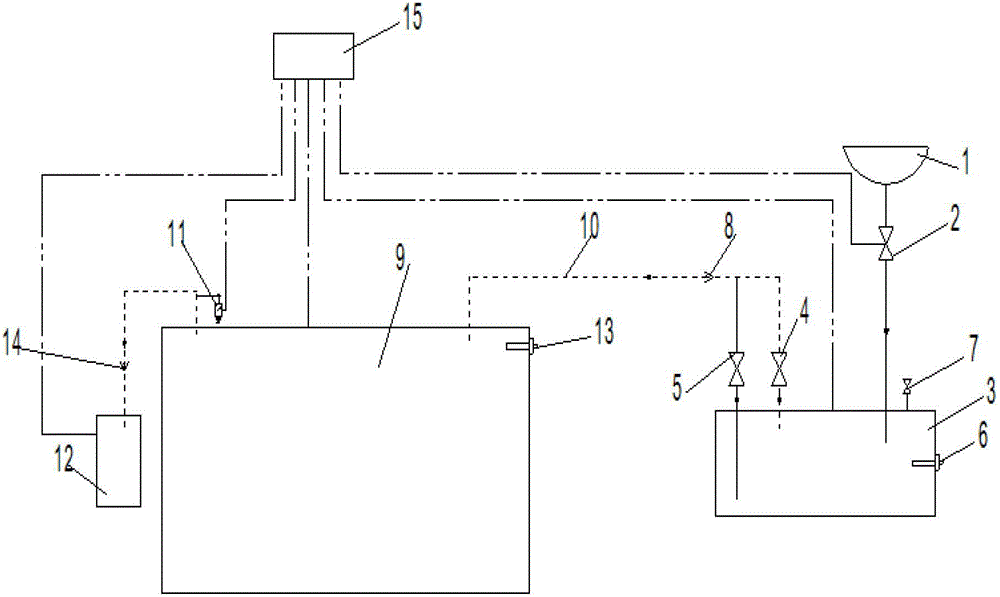

Automatic electrical control system of pneumatic wheat conveying system

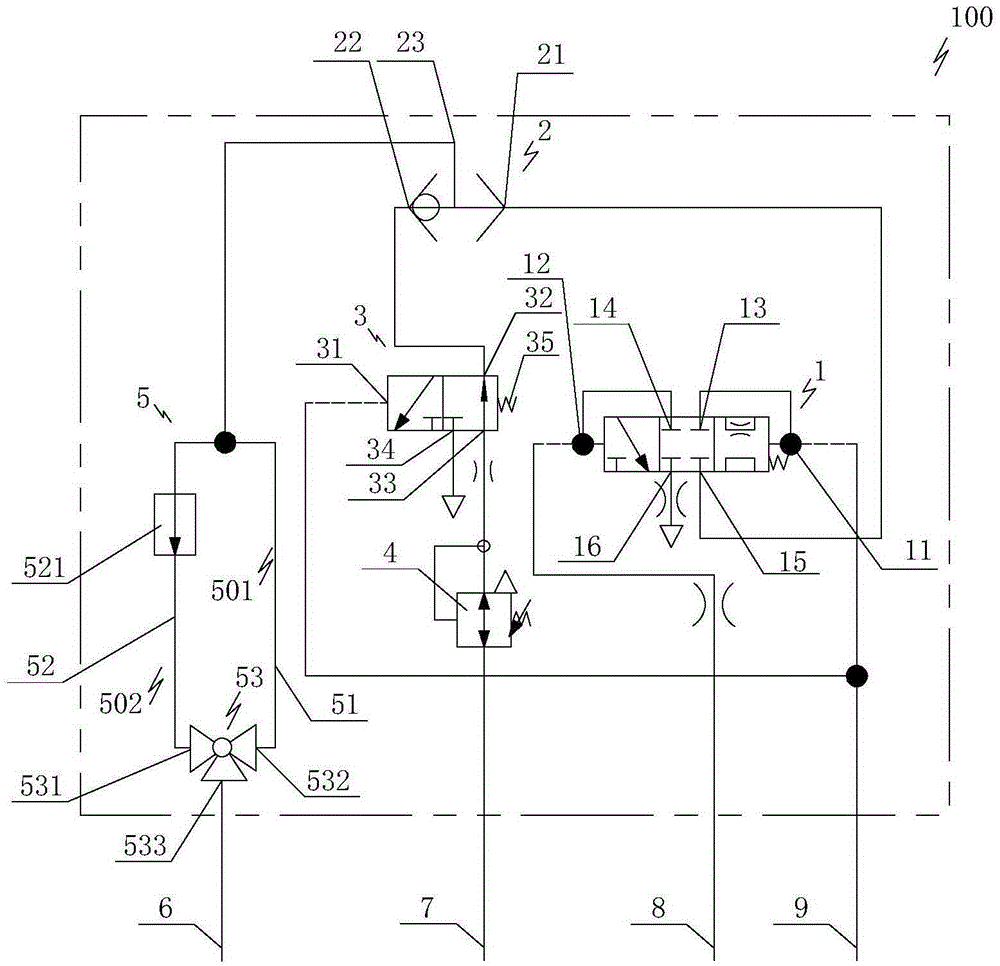

InactiveCN104555456AEnsure better control thanSave compressed airBulk conveyorsExhaust valveFreeze-drying

The invention relates to an automatic electrical control system of a pneumatic wheat conveying system. The automatic electrical control system comprise a PLC system 1, an industrial control or DCS 2, an air compressor and freezing and drying motor 3, an electric contact pressure gauge 4, a pressure adjusting valve 5, an upper air feed valve 6, a pneumatic exhaust valve 7, a pressure transducer 8, a pneumatic feed valve 9, a pneumatic pre-closing valve 10, a pneumatic discharge valve 111, a high level material level meter 12, an air pressurizing device 13, a pulse air blade valve 14, a pneumatic change valve 15, a high level material level meter 16, a pressure relief valve 17, a pulse reverse bag blowing type material bin dust remover pulse valve 18, a pulse reverse bag blowing type material bin dust remover air guiding fan motor 19, a low level material level meter 20, a pneumatic gate valve 21, a signal transmission cable 22, a weighing sensor 23 and a mass flow meter 24. The automatic electrical control system is characterized in that the system is controlled by the PLC system 1 in a concentrated manner, the material-air ratio ranges from 20 to 22, and the pipeline equipment is adjusted according to the material-air ratio.

Owner:NINGXIA JIAXIANG AUTOMATIC CONTROL TECH

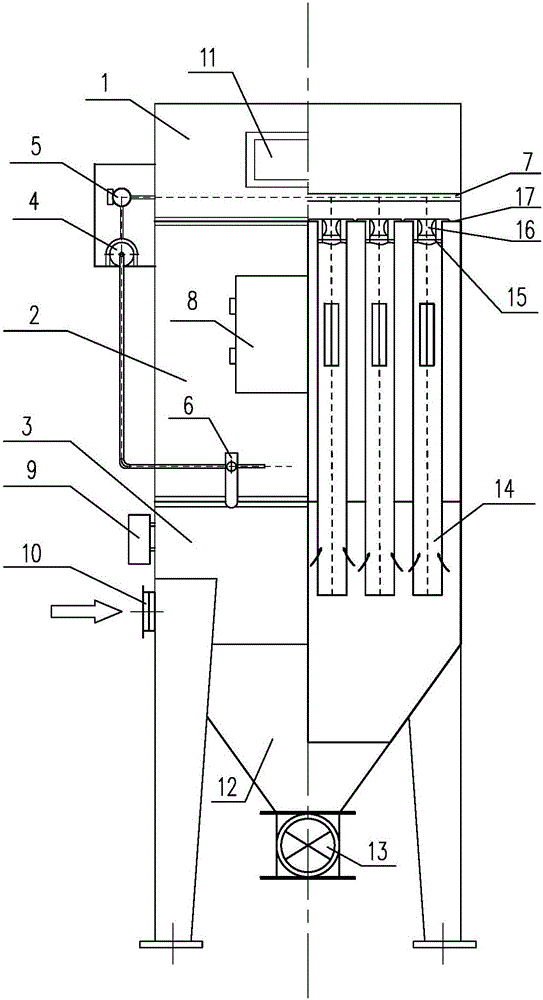

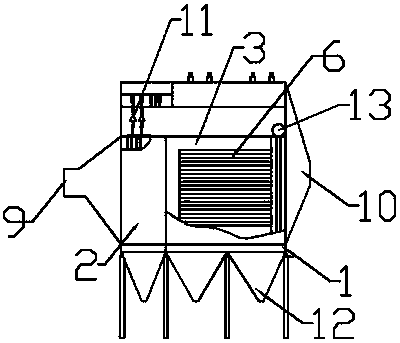

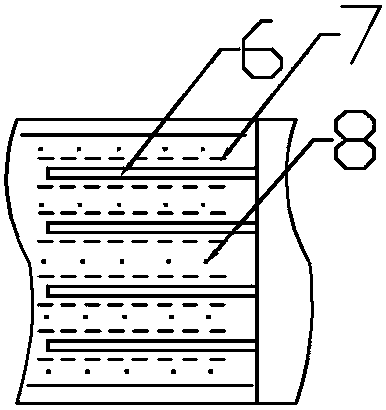

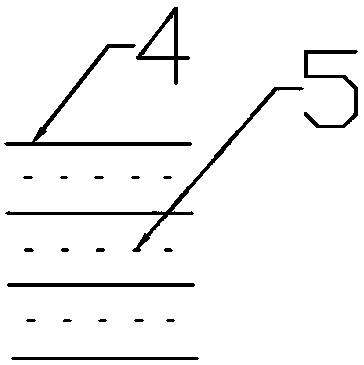

Pulse bag type dust collector device

InactiveCN105920945AGuaranteed uptimeGood dust removalDispersed particle filtrationInlet channelDifferential pressure

The invention discloses a pulse bag type dust collector device. The pulse bag type dust collector device comprises an upper box body, a middle box body, a lower box body, an ash bucket, a dust collection mechanism and an ash cleaning mechanism, wherein a pulse controller of the ash cleaning mechanism is connected with a micro-differential pressure controller and a pulse valve; an outlet of the pulse valve is connected with a blowing pipe; the blowing pipe is communicated with an inner cavity of a filter bag through a venturi tube; an air inlet channel of the pulse valve is provided with an air packet structure; an air inlet pipeline of the air packet structure is provided with an air-water separator; the air-water separator can be used for improving the quality of compressed air and effectively preventing a phenomenon that water steam enters the cavity of the filter bag to influence the dust collection effect of the filter bag. A connection manner of the filter bag adopts a self-locking device and the filter bag is convenient to mount and replace; the service life of the filter bag can be effectively prolonged. Furthermore, an access door and a star-shaped ash unloading valve are tightly compacted and sealed by asbestos gaskets, so that the sealing performance of a dust collector is improved and the leakage is avoided. The pulse bag type dust collector device is simple in structure, high in dust collection efficiency and practical and flexible; an ash cleaning process can be automatically realized and the operation is stable.

Owner:山东淙汇机电装备集团有限公司

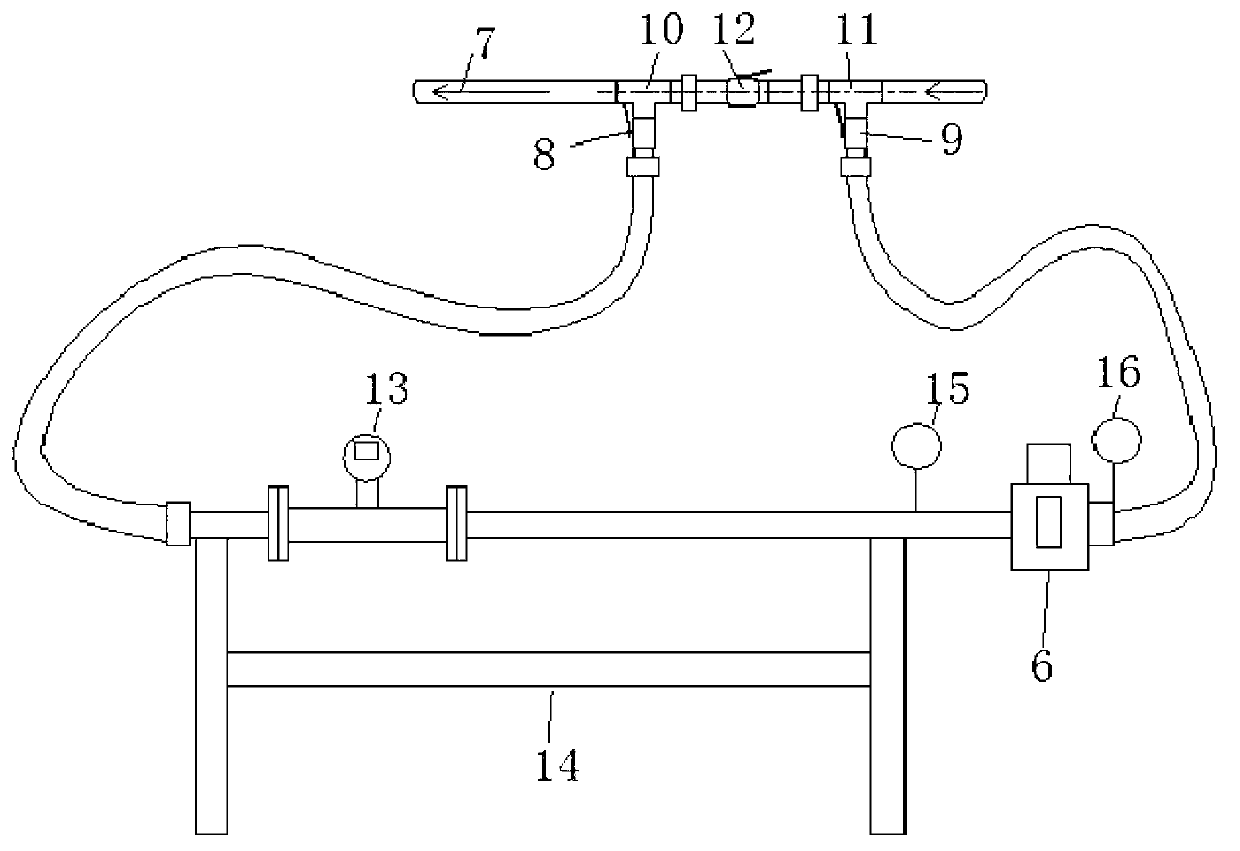

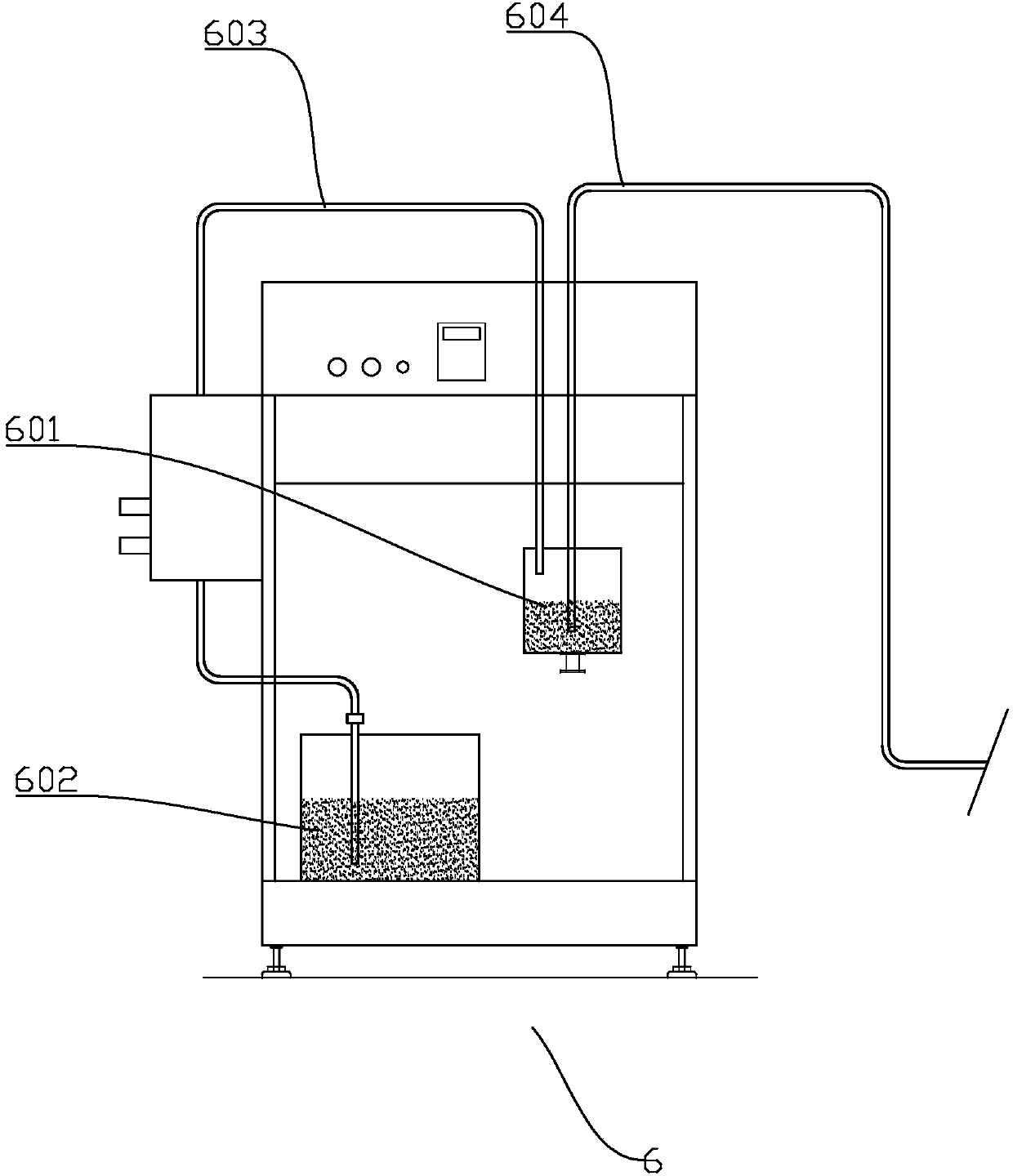

Crust breaking cylinder air throttle and testing device and testing method

The invention relates to an air throttle, a testing device and a testing method, and provides a crust breaking cylinder air throttle and the testing device and the testing method. The crust breaking cylinder air throttle comprises a pressure-regulating valve, an air supply pipe, an external guide pipe, a two-position three-way solenoid valve and a corresponded power supply control line of the two-position three-way solenoid valve; the testing device comprises a main gas path and a branch gas path, a three-way B, a ball valve C and a three-way D are arranged on the main gas path along the forward flow direction of the gas path in order; the branch gas path comprises two ball valves, the crust breaking cylinder air throttle, a flowmeter and two compression gauges; and the testing method comprises an gas path leakage point test of the testing device. The crust breaking cylinder air throttle outputs the pressure of a crust breaking cylinder by two grades according to the requirement, the gas usage efficiency of the crust breaking cylinder can be greatly enhanced; the provided testing device can be conveniently connected to an gas feed branch pipe of each electrolytic aluminium groove crust breaking cylinder in parallel; and the testing method can measure and calculate the gas capacity after using the air throttle by the crust breaking cylinder.

Owner:HANGZHOU ZETA TECH

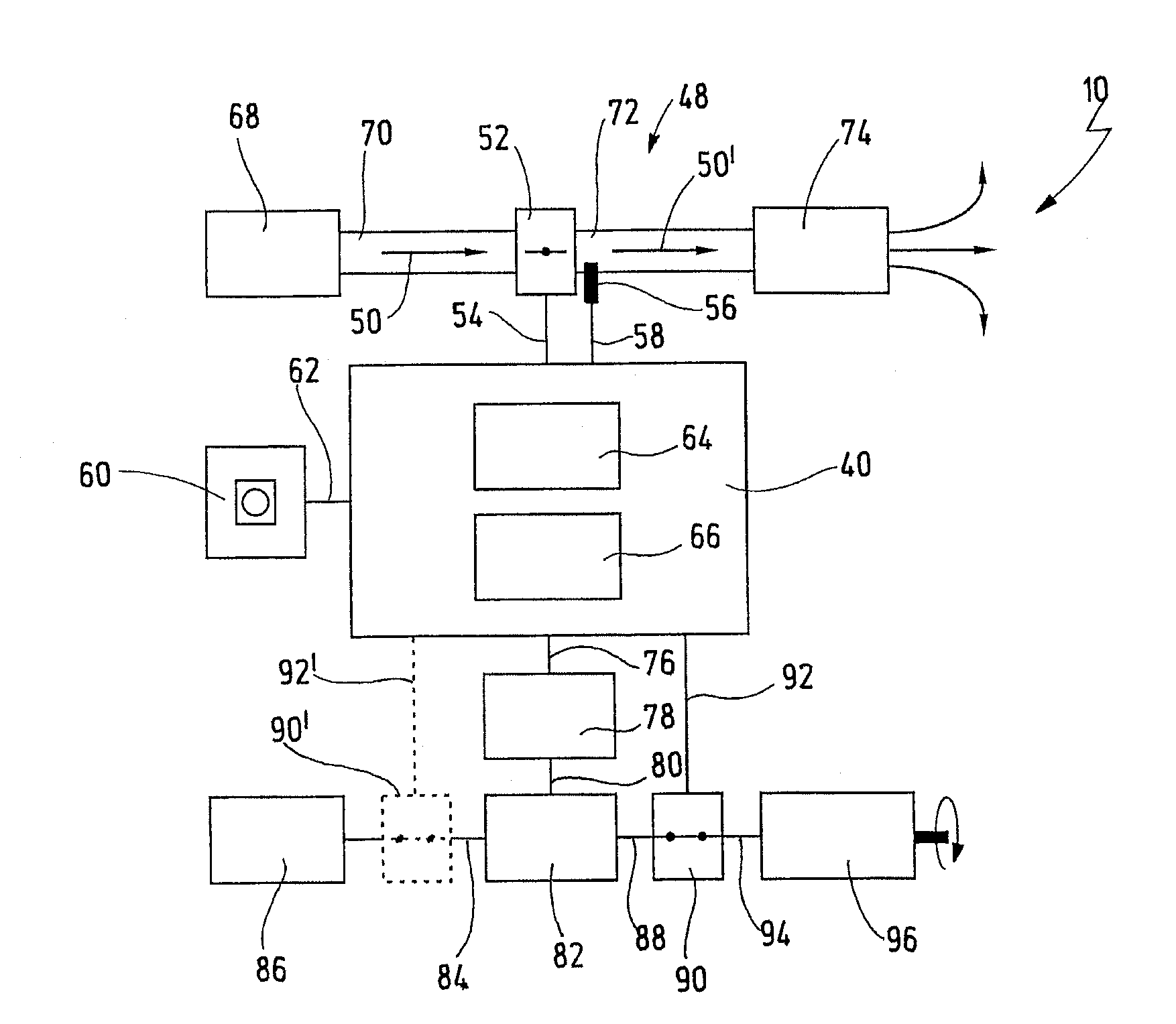

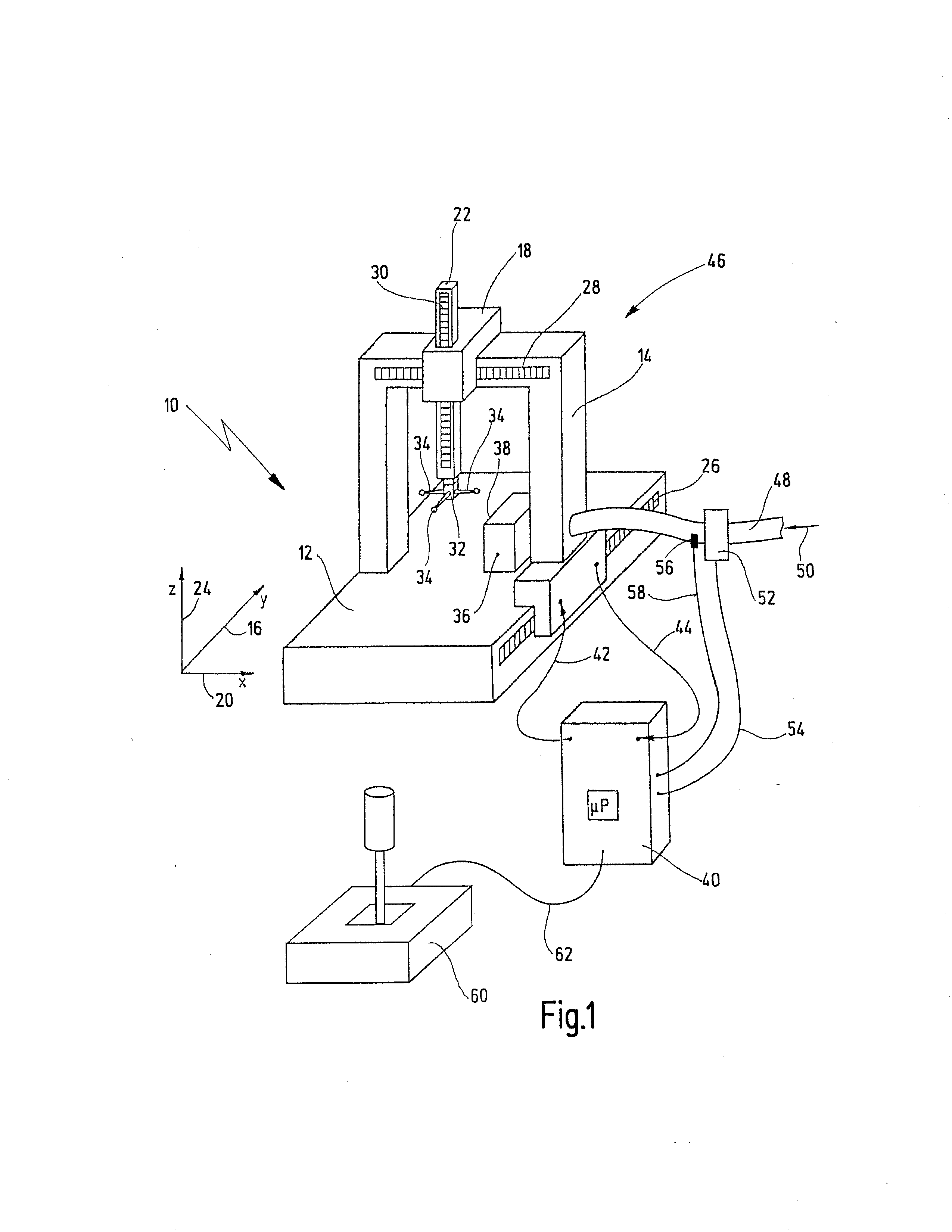

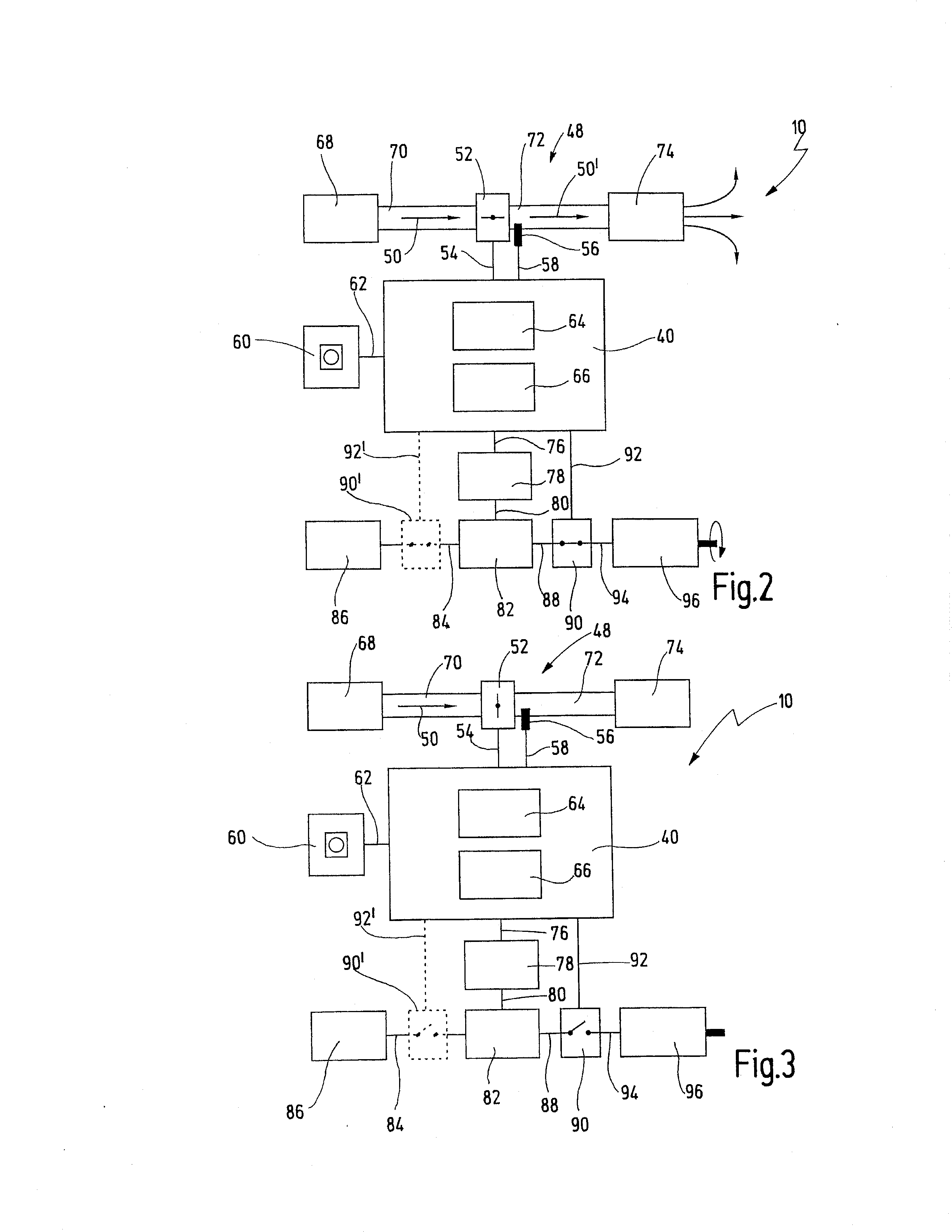

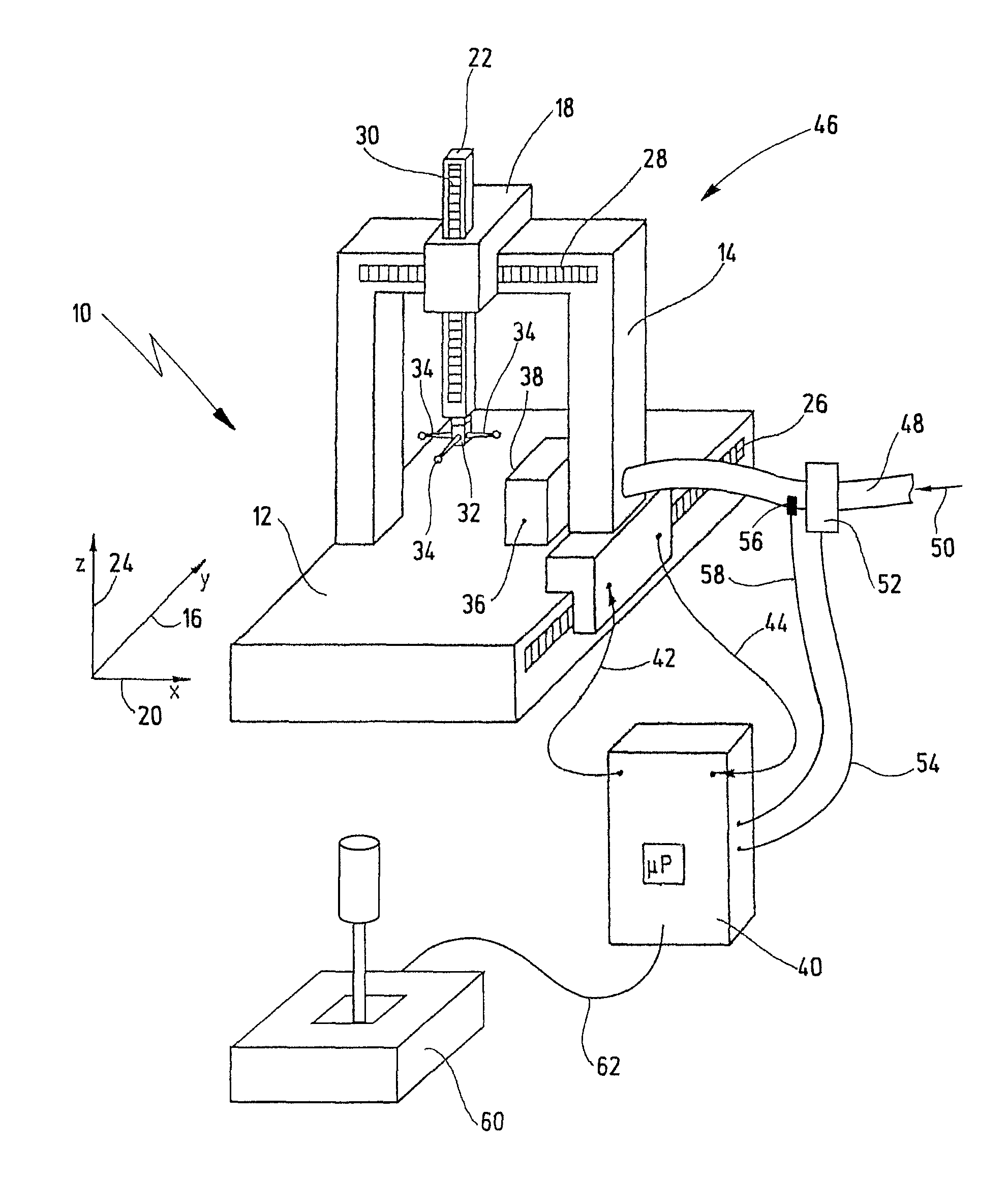

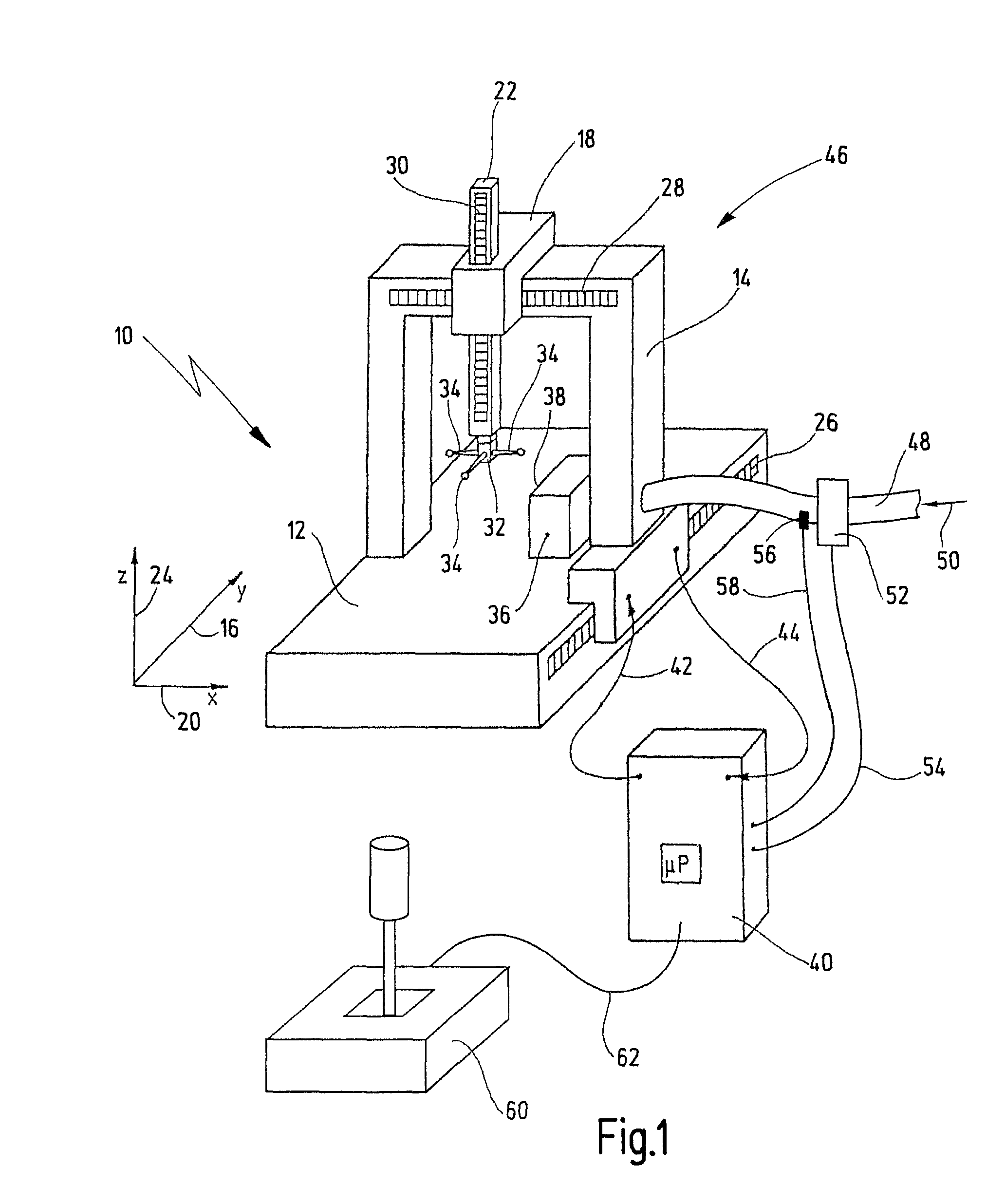

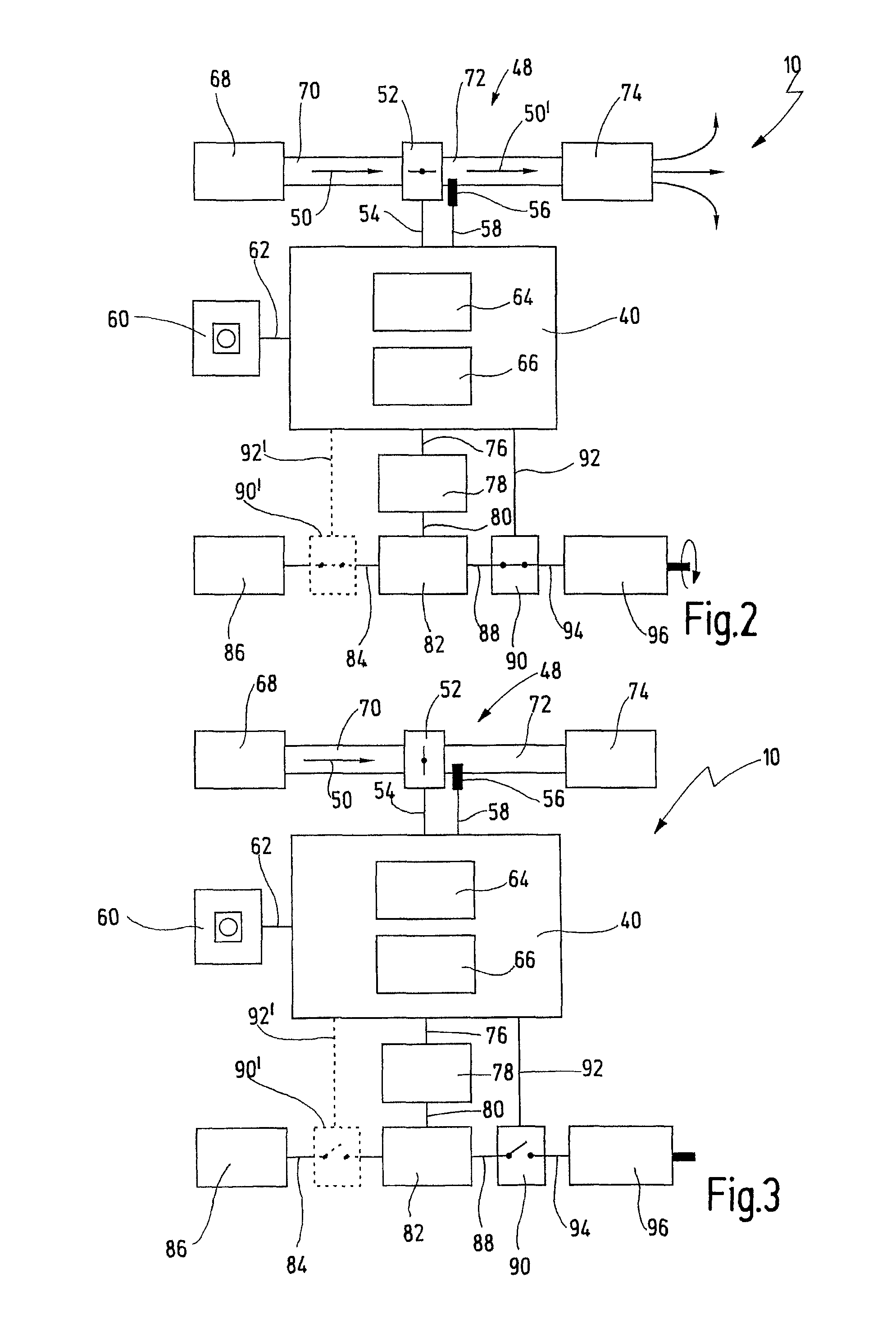

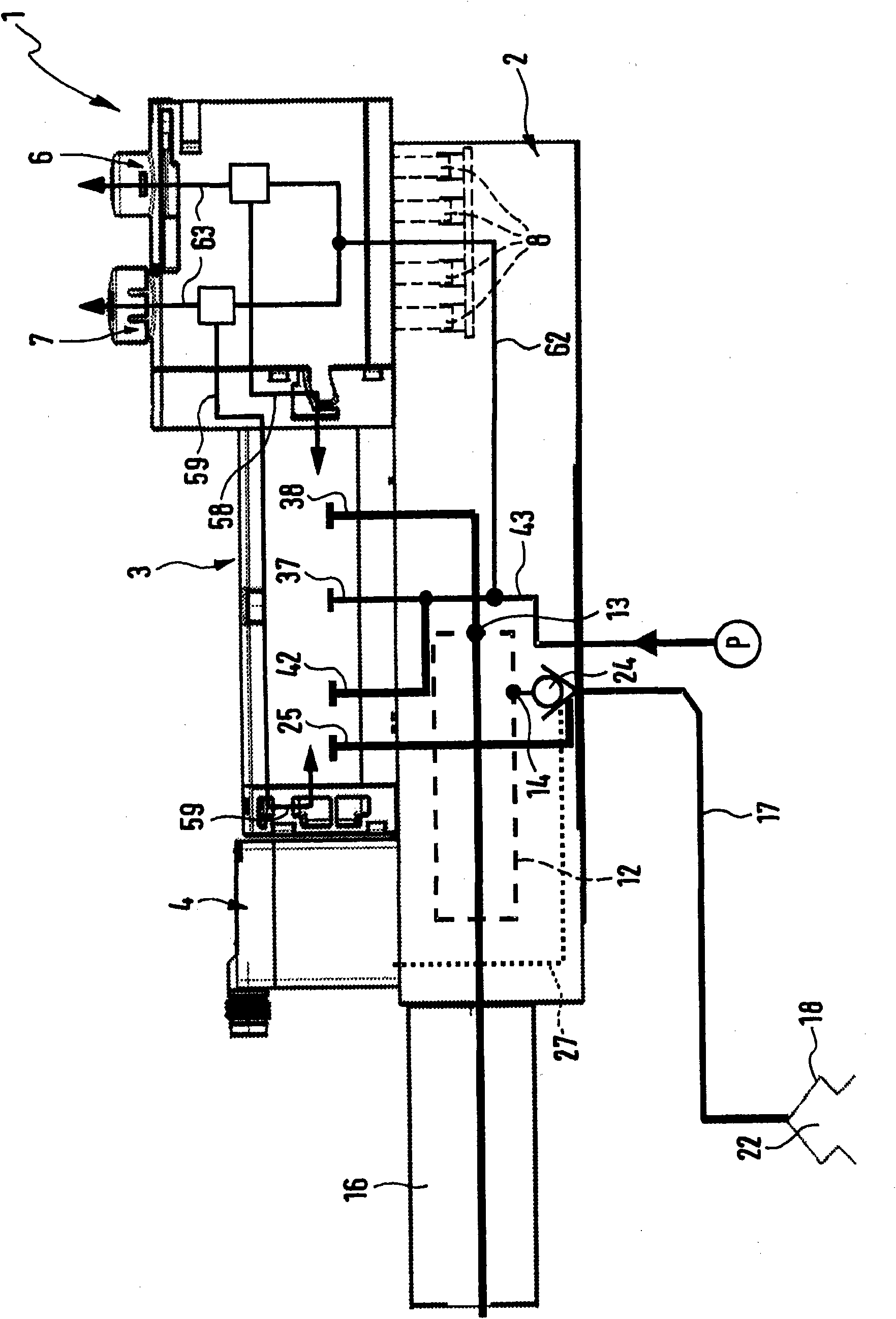

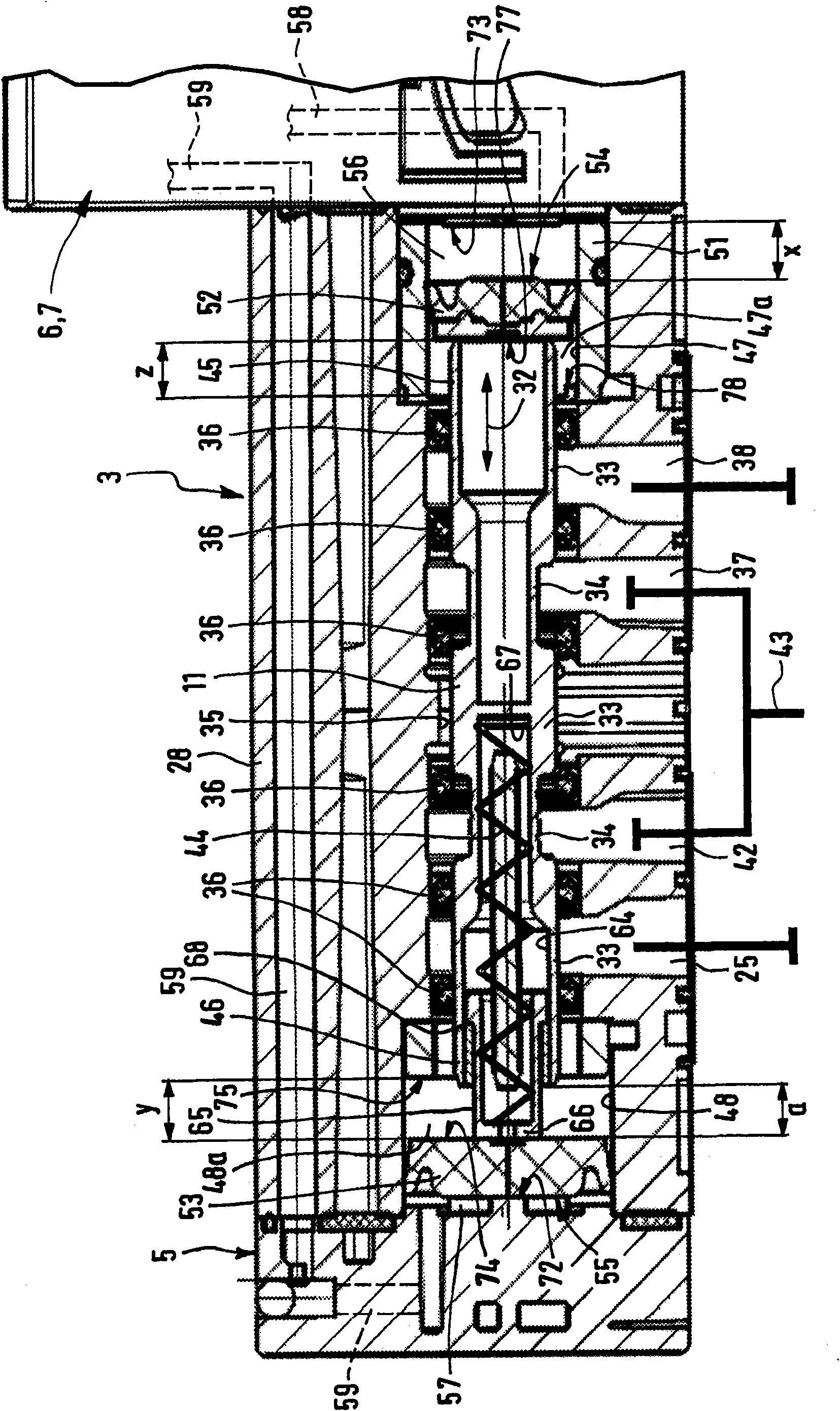

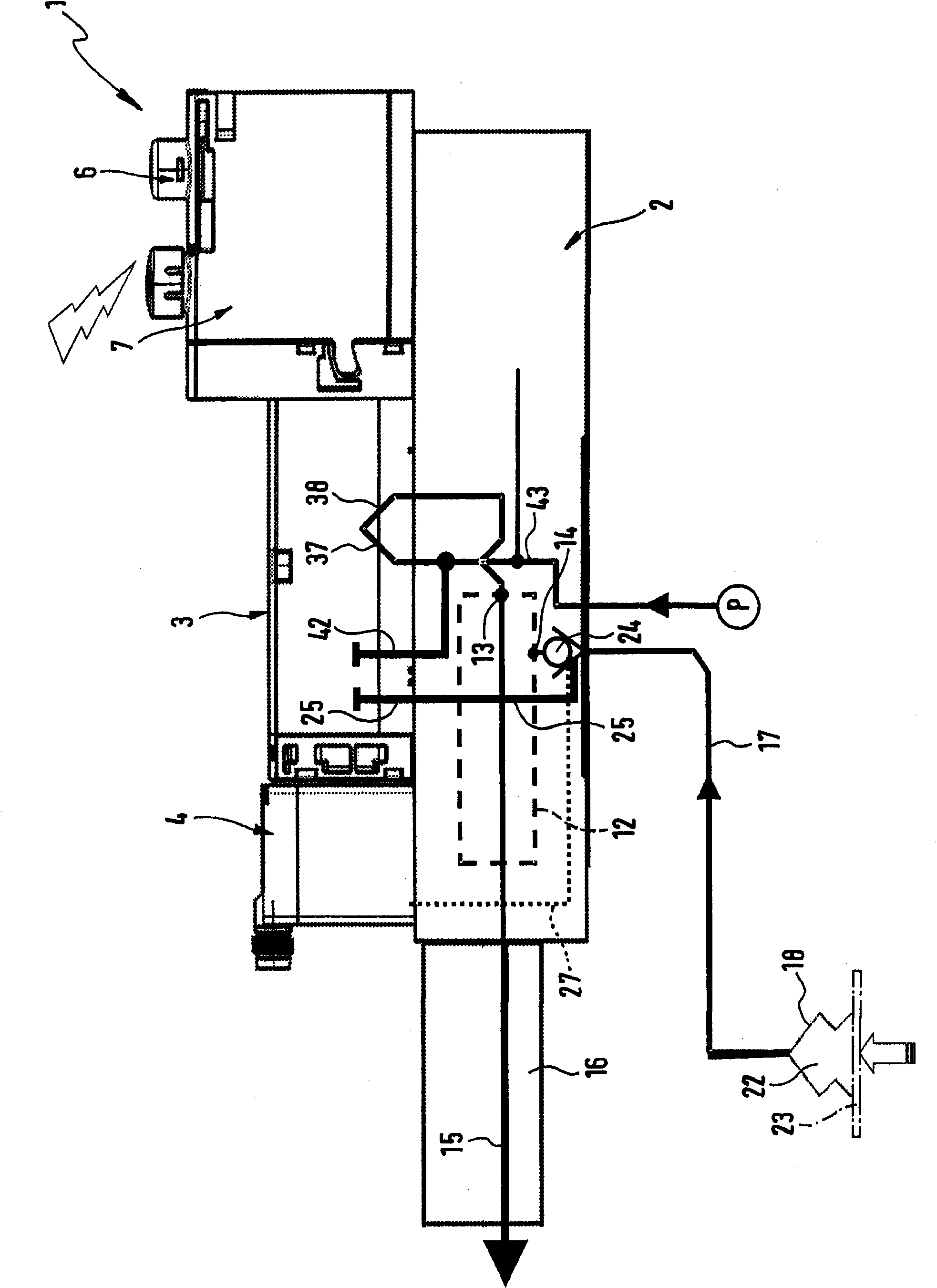

Machine having an air bearing and method for operating such a machine

ActiveUS20130181387A1Save compressed airHigh availabilityLarge fixed membersVicesAir bearingClosed loop

A machine has a frame structure for moving a machine head in one or more spatial directions. The frame structure comprises an actuator and an air bearing for moving the head. The machine also comprises a compressed air feed connected to the air bearing for providing a compressed air flow. A restrictor defines the compressed air flow to the air bearing. The machine has a first operating state, in which a high compressed air flow is defined and in which the actuator can be actuated. The machine has a second operating state, in which a compressed air flow lower than the high compressed air flow is defined. In the second operating state, the actuator is secured against actuation from a closed-loop position controller, while the closed-loop position controller is maintained in operation.

Owner:CARL ZEISS IND MESSTECHN GMBH

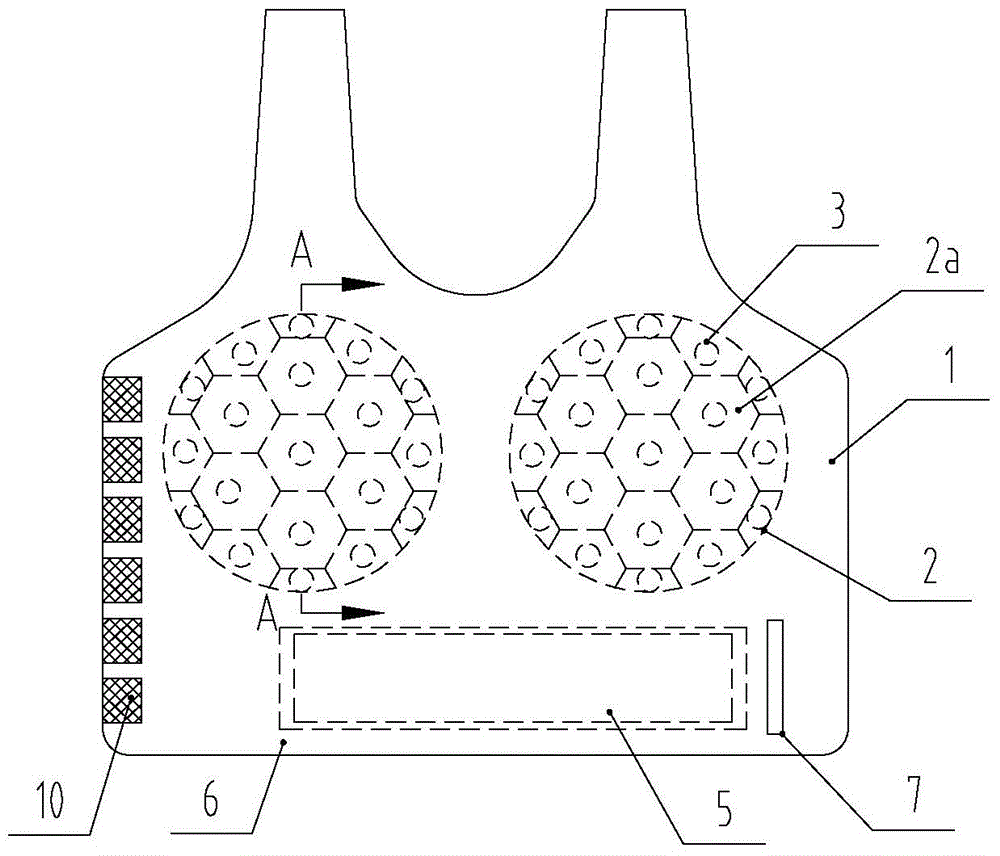

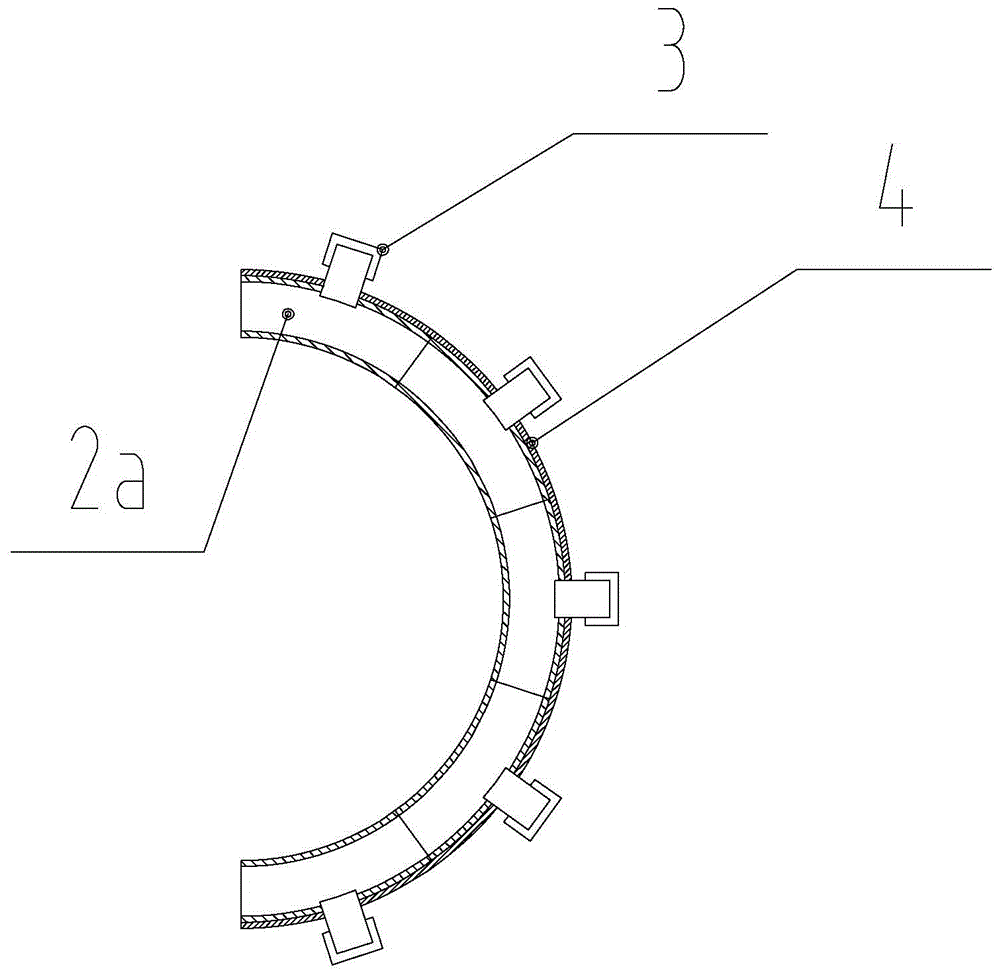

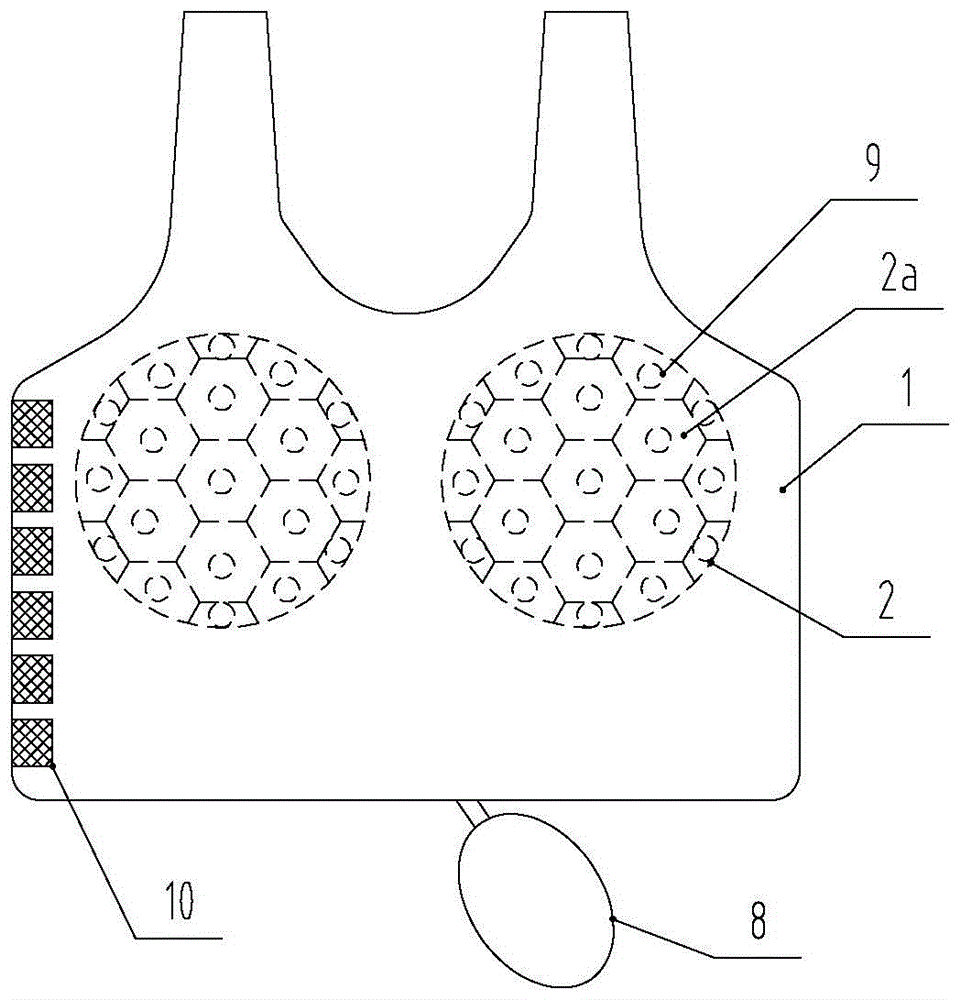

Pressure dressing device for breast surgery

InactiveCN103431949ASave compressed airGuaranteed pressure effectBreast bandagesAbdomen bandagesRight breastAtmospheric pressure

Owner:THE FIRST AFFILIATED HOSPITAL OF THIRD MILITARY MEDICAL UNIVERSITY OF PLA

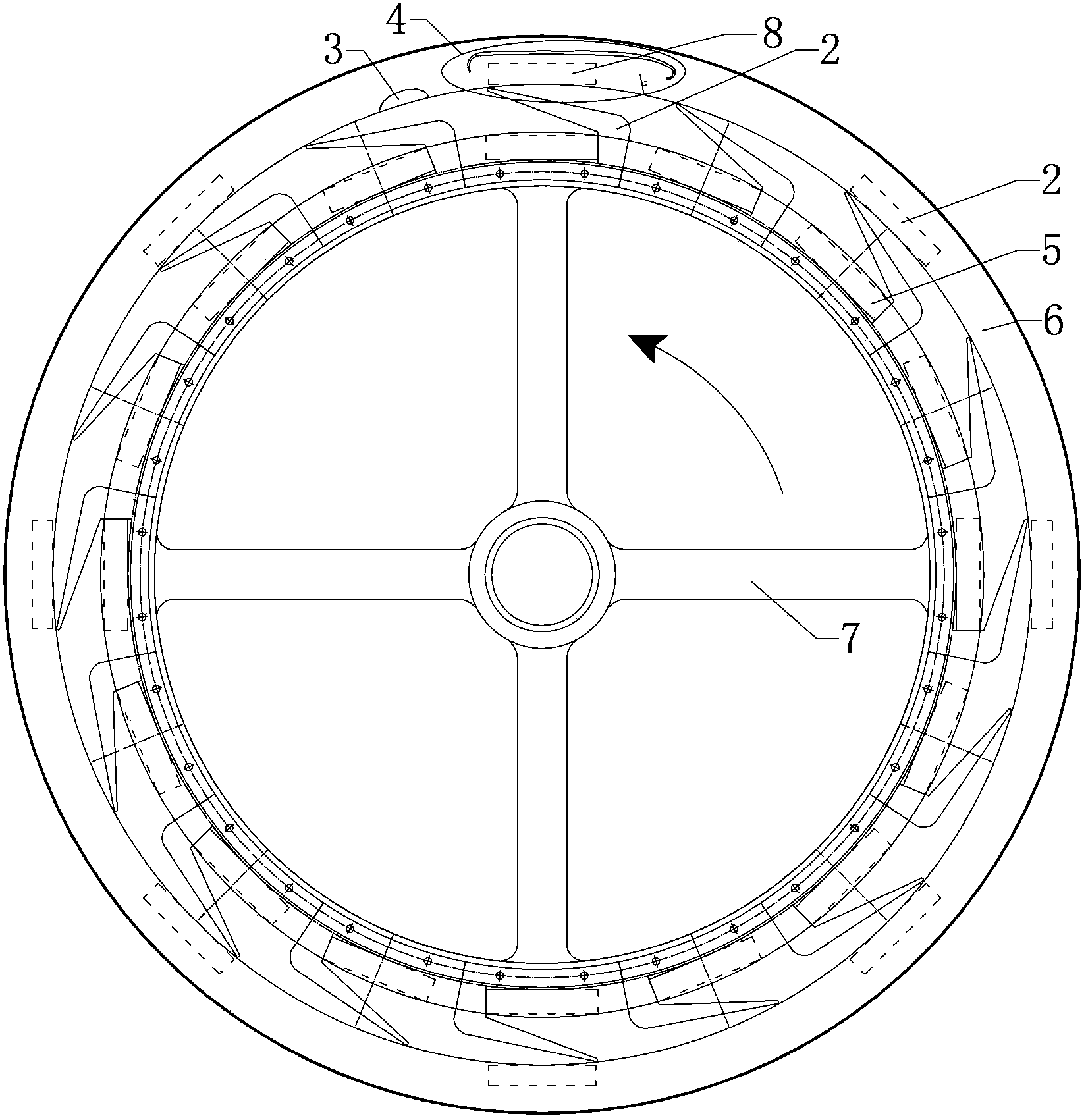

Material picking device

InactiveCN105057216ASave the tedious process of weighing and identifying one by oneFocusGradingConstant forceEngineering

The invention relates to a material picking device which comprises a rotary disc and a feeding barrel. Multiple counter bored holes are formed in the rotary disc and concentrically distributed in the upper surface of the rotary disc annularly. Air holes are formed in the bottoms of the counter bored holes. A rotary shaft is fixedly connected with the circle center of the rotary disc. The feeding barrel is of a cylindrical structure with a groove formed in the two ends. A lower outlet of the feeding barrel is exactly opposite to the corresponding counter bored hole. Cylindrical materials of different sizes and different structures can be picked up through the designed feeding barrel and too large materials cannot enter the feeding barrel. The condition in the feeding barrel can be conveniently observed through the axial groove of the feeding barrel. Air of constant force is blown through the air holes so as to blow the materials out, the distances of the falling points of the materials of different weights are different, and therefore the qualified materials are picked up. Therefore, more time and labor are saved for picking up the materials mechanically instead of manually and the cost reduction effect can be achieved.

Owner:SUZHOU SUTENG ELECTRONICS TECH

Graywater contamination collecting system for vehicle, control method and vehicle

The invention relates to a graywater contamination collecting system for a vehicle, a control method and a vehicle. The graywater contamination collecting system for the vehicle comprises a graywaterdrainage device, a graywater temporary storage box, a water closet, a water tank, a graywater contamination box, a flushing switch and an electric control unit; the water tank is connected with a water flushing pipe of the water closet through a water supply pipeline; a booster water pump, an energy storage tank and a water flushing electromagnetic valve are connected to the water flushing pipe inseries in sequence, wherein the booster water pump is used for increasing the water flushing pressure; the energy storage tank is used for temporarily storing pressure water; and the water flushing electromagnetic valve is used for controlling the closing and opening of the water flushing pipe; the bottom of the water closet is connected with the graywater contamination box through a blow-off pipe; the graywater drainage device is connected with the graywater temporary storage box through a first water drainage pipe; the graywater temporary storage box is connected with the graywater contamination box through a second water drainage pipe; a first electric gate valve is arranged on the blow-off pipe; a second electric gate valve is connected to the second water drainage pipe in series; anelectric vacuum pump used for keeping a vacuum state of the graywater contamination box is connected to the graywater contamination box; and the flushing switch, the water flushing electromagnetic valve, the first electric gate valve, the second electric gate valve, the booster water pump and the electric vacuum pump are connected with the electric control unit. The graywater contamination collecting system for the vehicle has the characteristics of less system equipment, simple and compact structure, low fault rate, guaranteed water flushing effect and the like.

Owner:QINGDAO YATONGDA RAILWAY EQUIP CO LTD

Full-automatic back-sealing multi-row particle packaging machine compound punching and cutting device

The invention discloses a full-automatic back-sealing multi-row particle packaging machine compound punching and cutting device which comprises two standing seats and punching and cutting seats. A screw rod is vertically installed on each standing seat, the two ends of the punching and cutting seats are slidably sleeved on the screw rods, nuts are arranged on the position, at the upper and lower ends of the punching and cutting seats, on the screw rods in a screwed mode correspondingly, and the nuts are used for adjusting and fixing the upper and lower positions of the punching and cutting seats. A plurality of concave dies are horizontally installed on the punching and cutting seats in an uniform distributed mode, and a plurality of plunger chips are arranged on the concave dies in a fitted mode. A row arranging device is arranged above the concave dies, a cooling device is arranged above the row arranging device, a waste collection device is arranged below the concave dies, and an anti-clamping bag device is arranged below the plunger chips. According to the technical scheme, the full-automatic back-sealing multi-row particle packaging machine compound punching and cutting devicehas the advantages of non-clamping bag, one-time cutting, punching easy-to-tear openings and fillets, stable punching and cutting performances, small punching and cutting force, saving compressed air, small impact, stable cutting process, high efficiency, and uniform and beautiful appearance of finished packaging bags after punching and cutting.

Owner:RUIAN SANYANG TECH

Machine having an air bearing and method for operating such a machine

ActiveUS8590875B2Save compressed airImprove usabilityMotor/generator/converter stoppersDC motor speed/torque controlAir bearingClosed loop

A machine has a frame structure for moving a machine head in one or more spatial directions. The frame structure comprises an actuator and an air bearing for moving the head. The machine also comprises a compressed air feed connected to the air bearing for providing a compressed air flow. A restrictor defines the compressed air flow to the air bearing. The machine has a first operating state, in which a high compressed air flow is defined and in which the actuator can be actuated. The machine has a second operating state, in which a compressed air flow lower than the high compressed air flow is defined. In the second operating state, the actuator is secured against actuation from a closed-loop position controller, while the closed-loop position controller is maintained in operation.

Owner:CARL ZEISS IND MESSTECHN GMBH

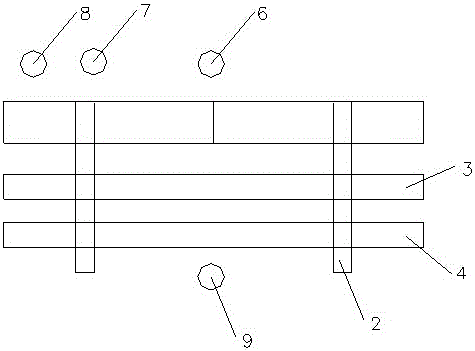

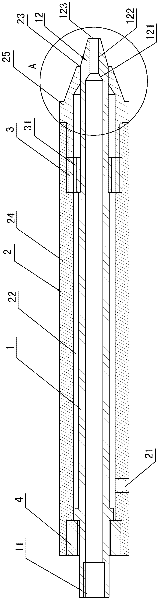

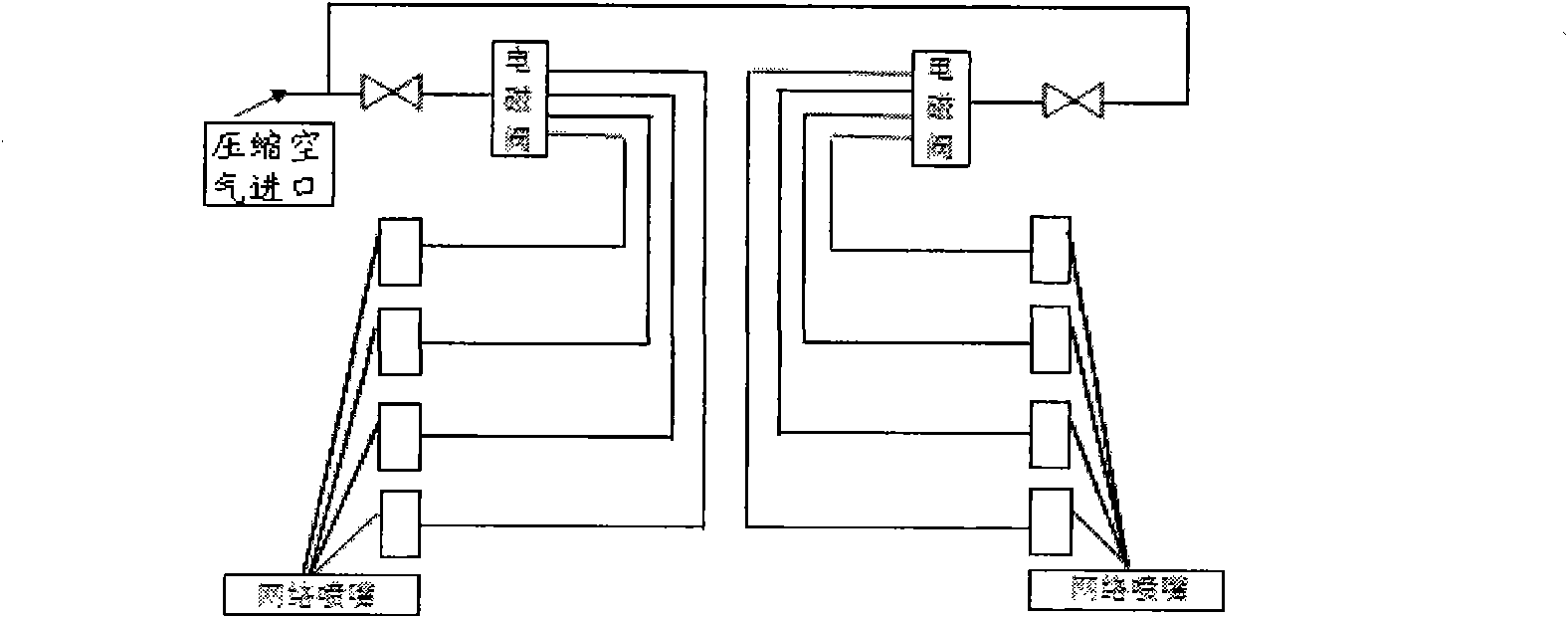

Connecting air pipe of polyester spinning pre-network

InactiveCN102373522ANo empty spray phenomenonSave compressed airTextiles and paperPolyesterCross connection

The invention relates to the technical field of a polyester spinning network system and particularly relates to a connecting air pipe of a polyester spinning pre-network of a winding formation device. The connecting air pipe comprises plural four-outlet electromagnetic valves, wherein four outlets of each electromagnetic valve are respectively connected with four air pipes, each air pipe is connected with a network spray nozzle in a spindle position, and the adjacent two of the four air pipes of the every adjacent two electromagnetic valve outlets are cross-connected onto the network spray nozzles. Due to the adoption of cross-connection, the empty spraying phenomena of the network spray nozzles can be avoided and the compressed air can be further saved.

Owner:KUANGDA TECH GRP CO LTD

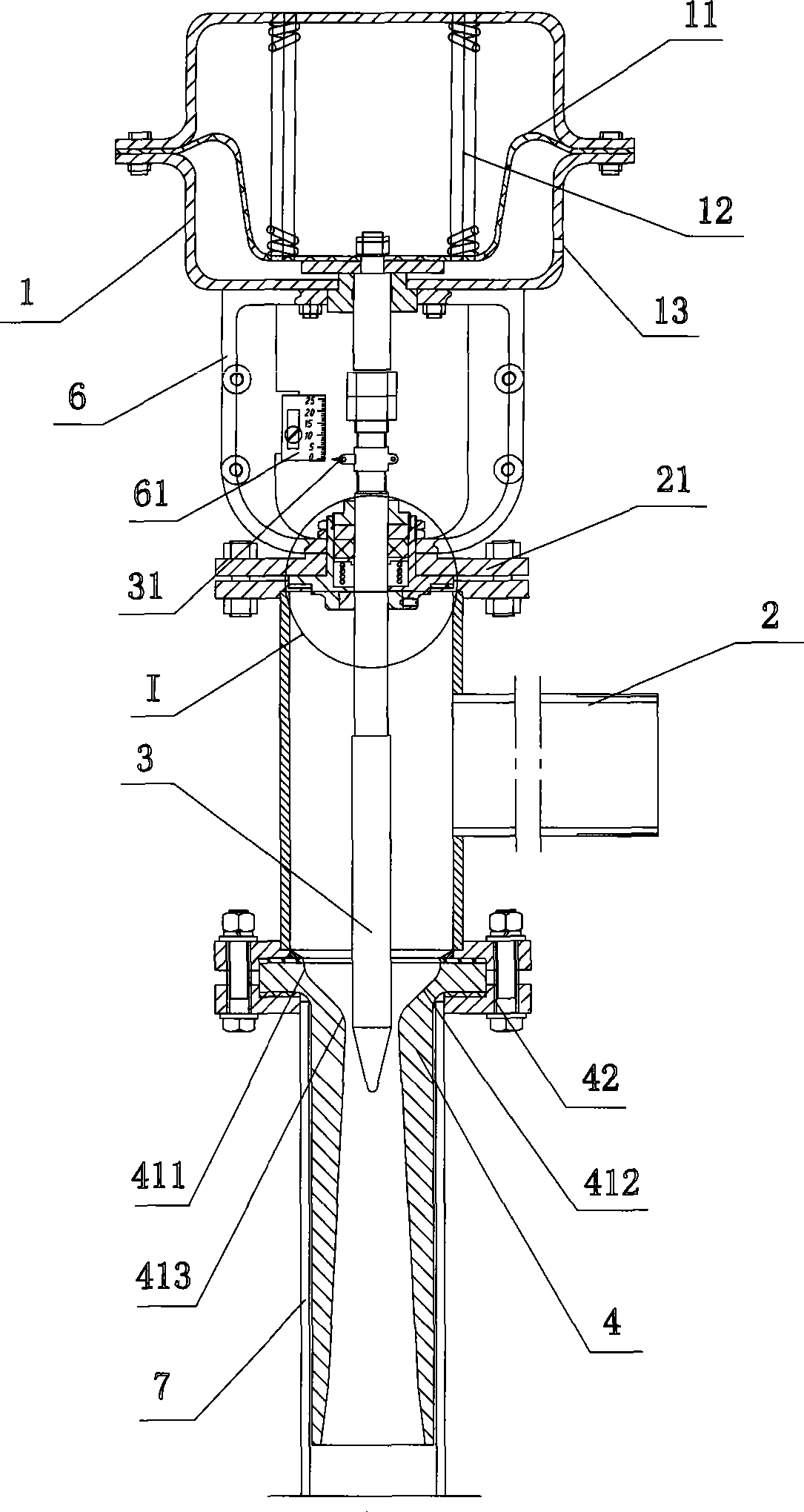

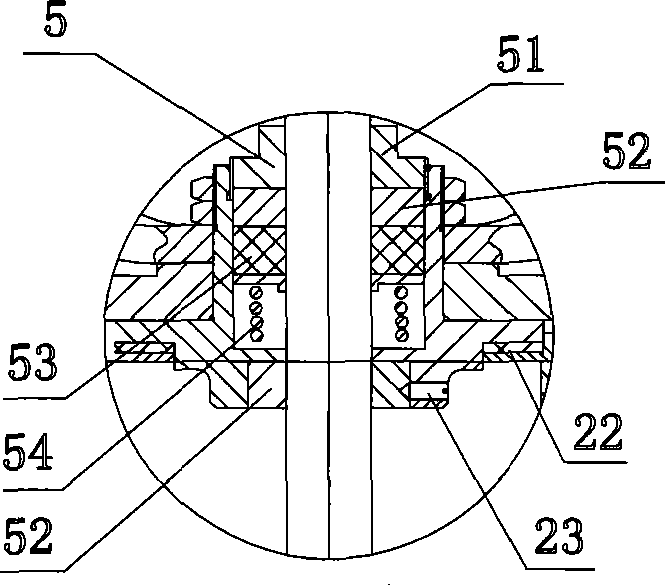

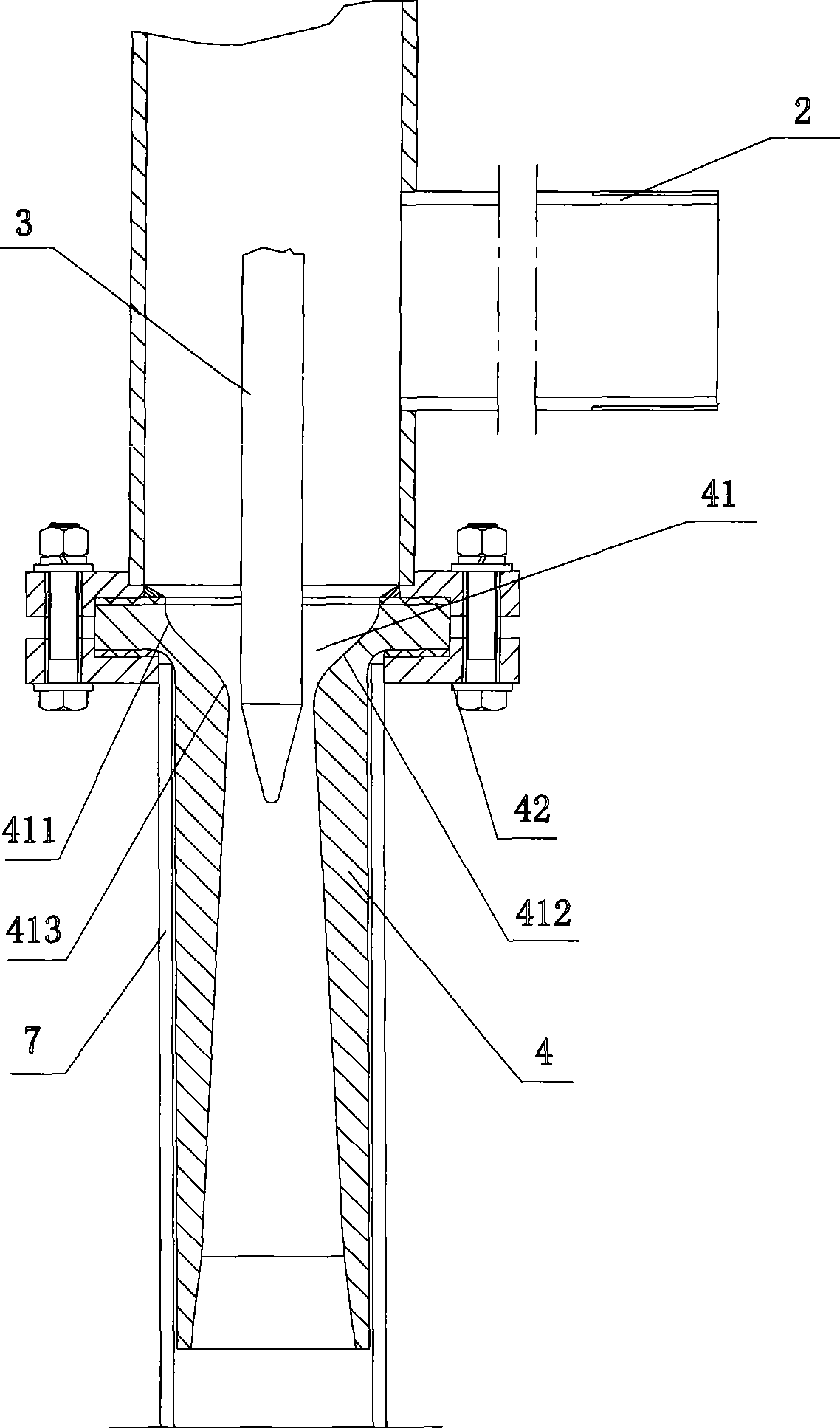

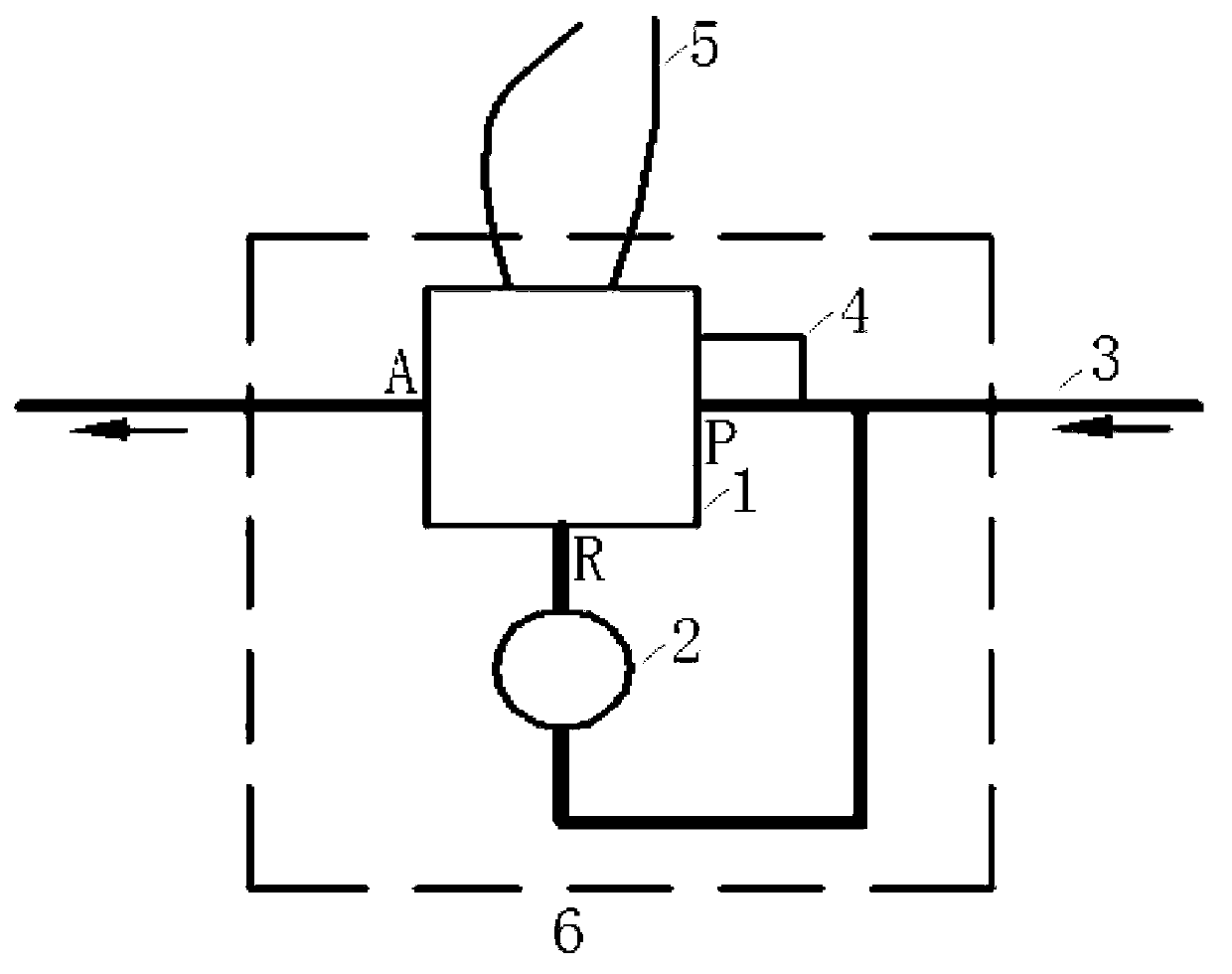

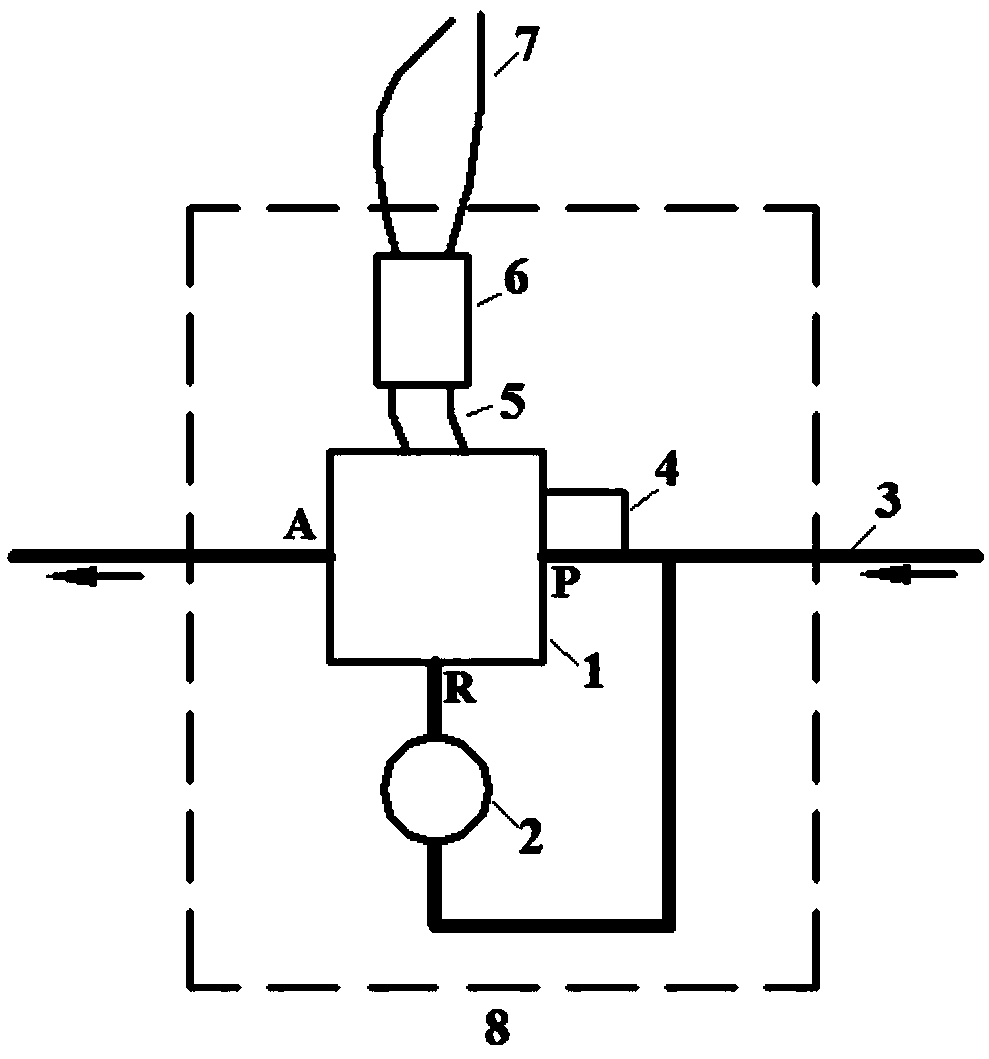

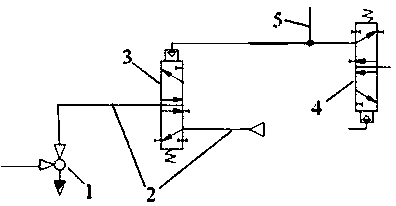

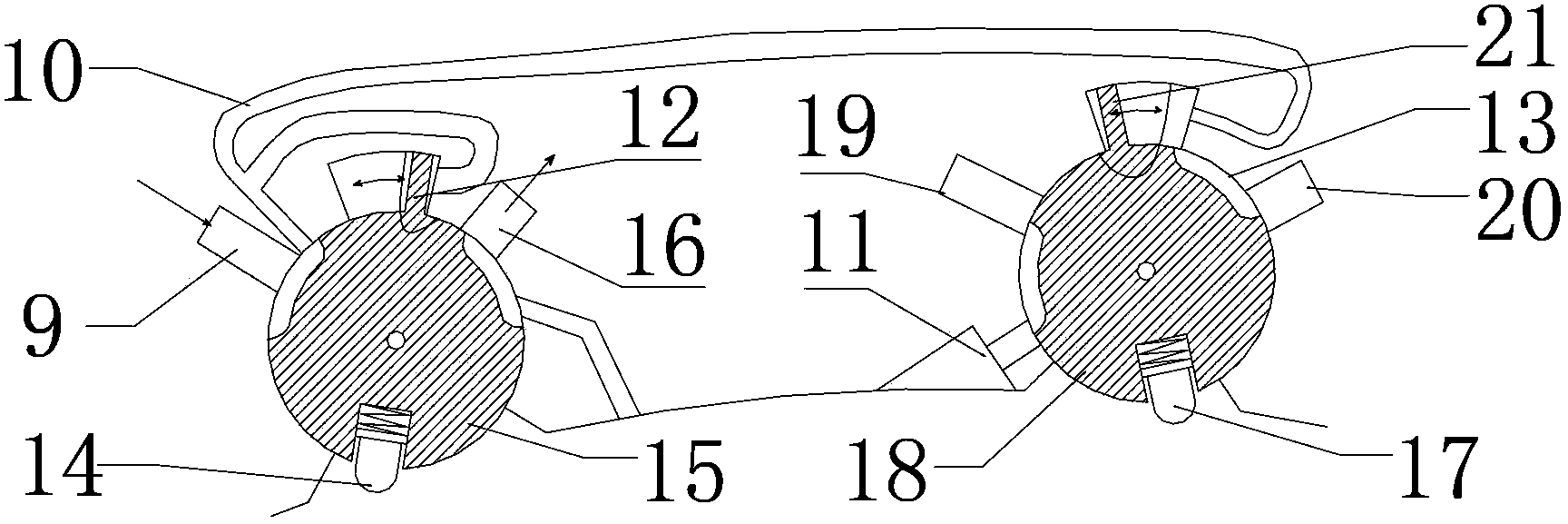

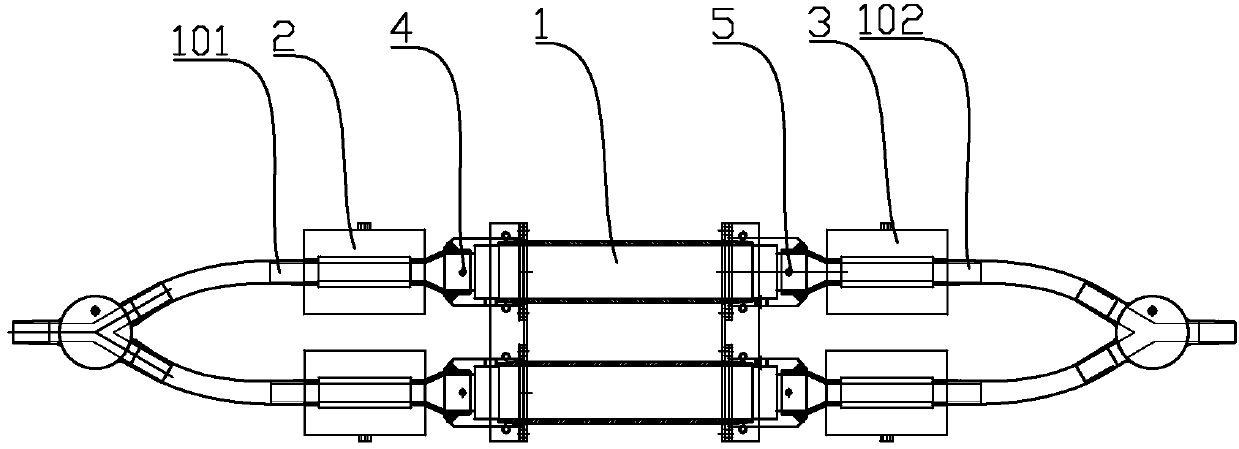

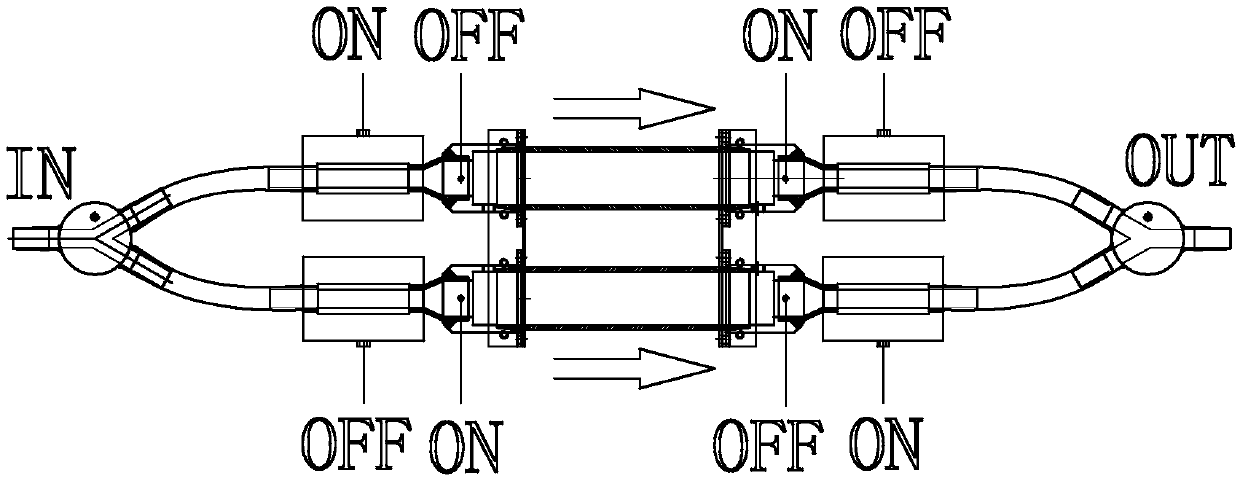

Air saving device and air supply method for crust breaking cylinder

ActiveCN103451677ADoes not change the shelling process requirementsImprove gas efficiencyEngineeringElectromagnetic valve

The invention relates to a novel air saving technique and aims to provide an air saving device and an air supply method for a crust breaking cylinder. An air supply pipe of the device comprises an air inlet pipe and an air outlet pipe; the device also comprises a two-position three-way electromagnetic valve, an external pilot pipe, a pressure regulating valve and a time relay, wherein the two-position three-way electromagnetic valve is provided with a hole P, a hole A and a hole R; the air outlet pipe is connected with the hole A, while the air inlet pipe is connected to the hole P; the pressure regulating valve is connected to the hole R and the air inlet pipe through pipelines, respectively; the external pilot pipe is connected to the two-position three-way electromagnetic valve and the air inlet pipe, respectively. The air saving device for the crust breaking cylinder, provided by the invention, is capable of improving the air utilization efficiency of the crust breaking cylinder without changing the crust breaking process requirements of the original crush breaking cylinder, and also saving compressed air and achieving the purposes of saving energy and reducing consumption; the air saving device can be connected in parallel to an air supply branch pipe of each electrolytic aluminium cell crust breaking cylinder simply and conveniently.

Owner:HANGZHOU ZETA TECH

Embedded electric-bag composite dust collector with fore electric fields and horizontally arranged filter bags

The invention discloses an embedded electric-bag composite dust collector with fore electric fields and horizontally arranged filter bags. The filter bags are horizontally arranged in a filter bag dust collection area; two ends, i.e., two points of the filter bags are horizontally fixed and suspended; the filter bags and the adjacent electric fields are alternately arranged. The embedded electric-bag composite dust collector provided by the invention is simple in structure design and outstanding in using effect; a backward electric bag composite area is fixedly positioned with two end points through the horizontally arranged filter bags, so that the positioning accuracy is improved, and the collision between the filter bags is avoided; the electric fields and the filter bags are alternately arranged, and a backward electric field dust collection area can capture dust which cannot fall into an ash bucket during an adjacent filter bag ash removal process, so that the problem of reentrainment of dust brought by an upflow can be effectively avoided, an ash removal effect is improved, meanwhile, the length of each filter bag is greatly prolonged, the filter bags can compactly fill the dust collector space, the electric fields and the filter bags are mutually coupled fully, the occupied area of the dust collector is reduced, the injection of compressed air is reduced, a pulse valve and an injection pipe are saved, and the cost and the operation and maintenance cost of the dust collector are reduced.

Owner:SUQIAN LONGKING ECOTECH

Vacuum generating device of wafer chuck

InactiveCN103531512AGuaranteed synchronizationSave compressed airSemiconductor/solid-state device manufacturingEngineeringElectrical and Electronics engineering

The invention discloses a vacuum generating device of a wafer chuck. The device comprises a vacuum generator and a compressed air pipeline which are connected by a pipeline, wherein the vacuum generator provides vacuum for the wafer chuck. The device further comprises an air valve which is arranged between the vacuum generator and the compressed air pipeline. A control end of the air valve is connected with a gas supply pipeline of a working valve of an external wafer chuck through a pipeline. When the gas supply pipeline supplies compressed air to the working valve, a part of the compressed air is separated to enter the control end of the air valve so that the air valve is switched on and the compressed air can be input to the vacuum generator. The wafer chuck and the vacuum generator are ensured to be synchronous; and when the vacuum generator does not need to work, a large amount of compressed air is saved, the production cost is saved, and the economic efficiency is improved.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Device for vacuum generation

InactiveCN101796334APrevent fallingPrevent vacuum dropMultiple way valvesValve housingsElectricityControl valves

A device for vacuum generation is proposed, said device comprising a valve device (3) having a valve member (11) that can be switched between a base position and a working position. The valve member (11) is associated with two oppositely oriented and differently sized actuating surfaces (54, 55), which can each be subjected to control air, controlled by an electro-pneumatic pilot control valve (6, 7). Using spring means (44), the valve member (11) is supported with respect to the larger actuating surface (55). By simultaneously actuating both pilot control valves (6, 7), the spring means (44) are tensioned in the base position and during subsequent power failure switch the valve member (11) back into the working position.

Owner:FESTO AG & CO KG

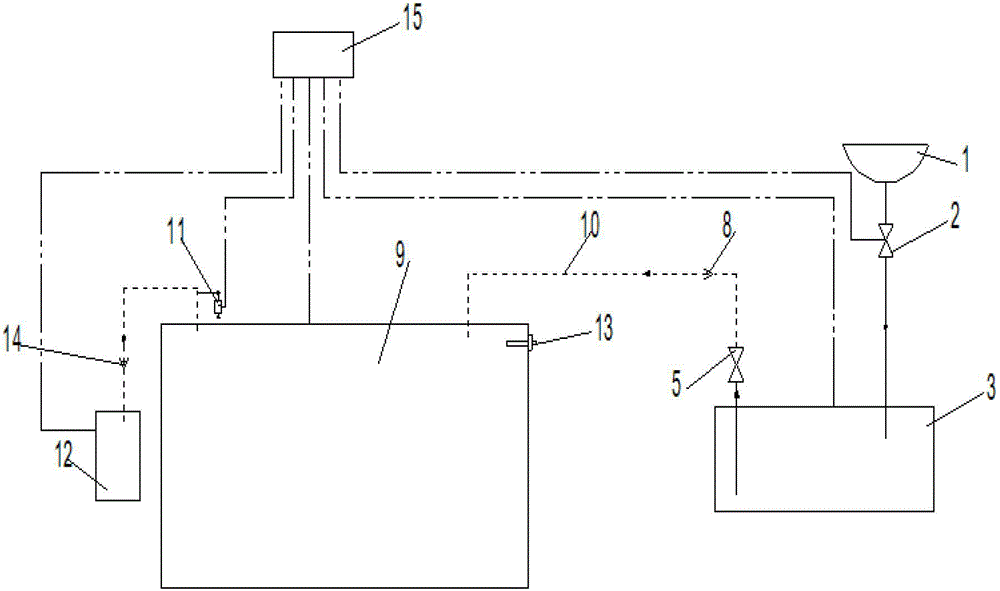

Passenger train vacuum toilet

ActiveCN102941857BSimple structureEasy to useSanitationPipeline transportProgrammable logic controller

The invention discloses a vacuum excrement collection device for a passenger train, which comprises a vacuum excrement collection device, a vacuum intermediate transition tank, a sewage terminal collection tank, a vacuum generation device, a PLC (programmable logic controller) and a vacuum switch, wherein the vacuum excrement collection device is connected with the vacuum intermediate transition tank which is connected with the sewage terminal collection tank, a first check valve and a transmission control valve are arranged on a conveying pipeline, the transmission control valve is connected with one end of the vacuum intermediate transition tank, one pipeline transports sewage and vacuum, the sewage terminal collection tank is connected with the vacuum generation device through a pipeline provided with a second check valve, the vacuum switch is connected with the sewage terminal collection tank which is provided with a liquid level sensor II, the PLC is connected with an electromagnetic valve I, an electromagnetic valve II, an electromagnetic valve III, the vacuum switch and the liquid level sensor II, one pipeline transports the sewage and the vacuum at the same time, compressed air is saved, the noises are reduced, the pipeline blockage is effectively reduced, and the pipeline is cleaned.

Owner:JIANGSU CRRC ENVIRONMENT CO LTD

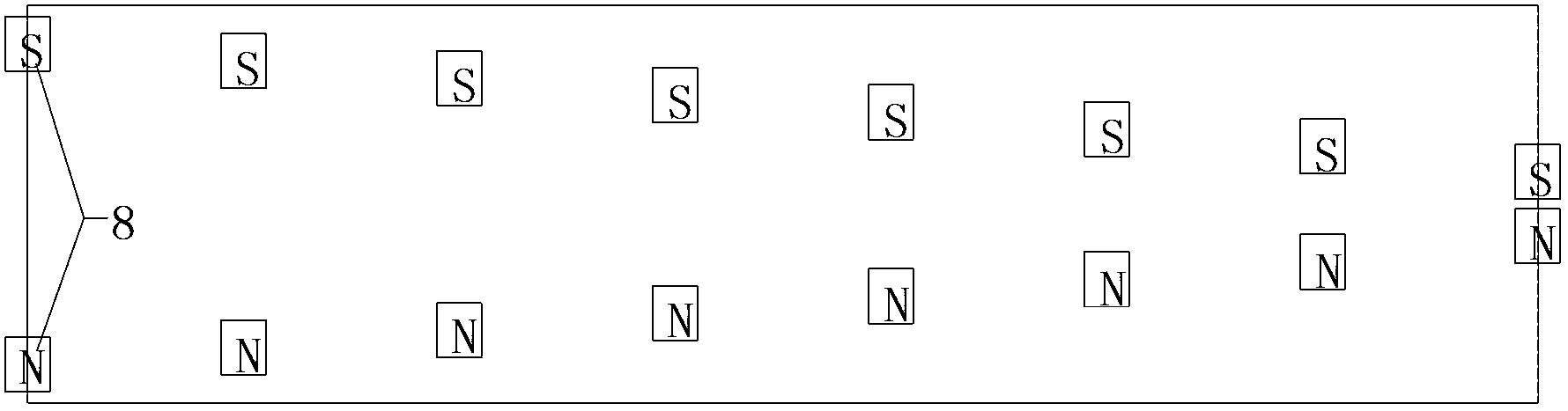

Turbine type gas magnetic engine

The invention belongs to the field of pneumatic system energy saving, and realizes a turbine type gas magnetic engine. Permanent magnets are respectively and additionally added on a stator and a rotor of a traditional pneumatic motor, the principle that different poles of the permanent magnets are mutually attracted, identical poles of the permanent magnets are mutually repelled is utilized, and a special mechanical structure and magnet layout is designed, so the single side of each blade receives the suction force of the stator permanent magnet, the anticlockwise rotating motive power is generated. In the blade dead point position, a gas distribution mechanism can be utilized for generating strong blowing force, so blades can fast rotate to pass the dead point. Compared with the traditional pneumatic motor, the consumption of compressed air is reduced, and the rotating motive power can be continuously obtained.

Owner:BEIHANG UNIV

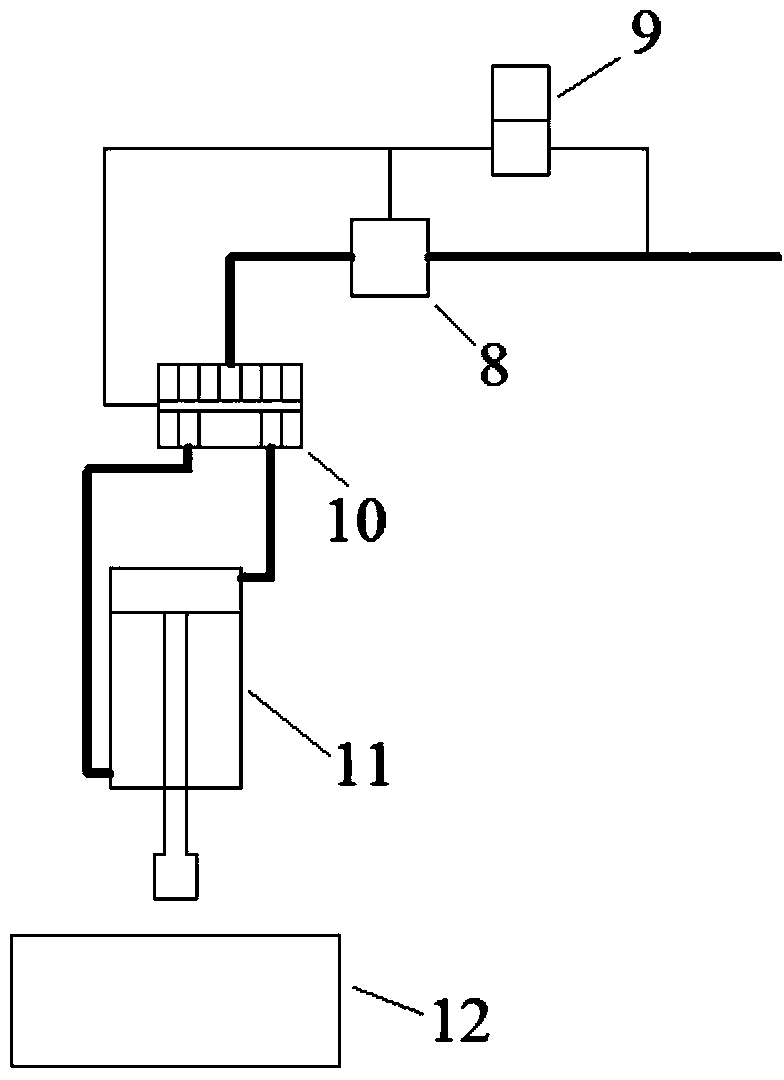

Vacuum extraction powder pump control system

ActiveCN107899768AImprove delivery efficiencyHigh densityLiquid supply arrangementsEngineeringVolumetric Mass Density

The invention discloses a vacuum extraction powder pump control system. The vacuum extraction powder pump control system comprises two or more powder conveying devices which are arranged in parallel.Each powder conveying device is provided with a powder cavity. Each powder cavity is provided with a feeding opening and a discharging opening. Each feeding opening is provided with a first opening and closing valve, and each discharging opening is provided with a second opening and closing valve, so that each feeding opening and each discharging opening are controlled to be opened and closed. Each powder cavity is connected with an air supply pipe and an air extraction pipe. Connection positions of air inlet pipes and the air extraction pipes are arranged to be close to the feeding openings and the discharging openings. The vacuum extraction powder pump control system is provided with the multiple powder conveying devices; in the working process, the multiple powder conveying devices canbe arranged to convey powder sequentially; powder conveying efficiency is improved; compressed air mingled in the powder conveying process is reduced; the powder conveying density is increased; production efficiency is improved; and the vacuum extraction powder pump control system has the cleaning function and is convenient to use and high in practicability.

Owner:ZHONGSHAN JUNHE ELECTRO MECHANICAL APP

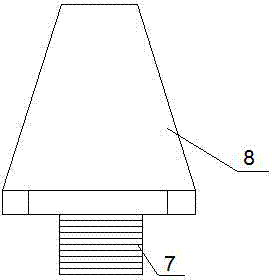

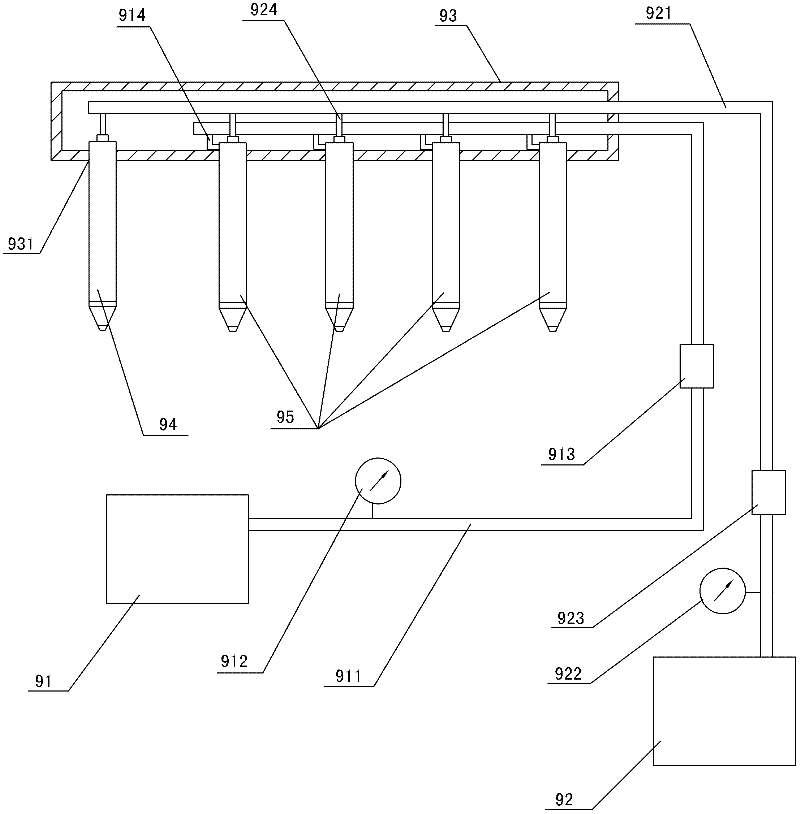

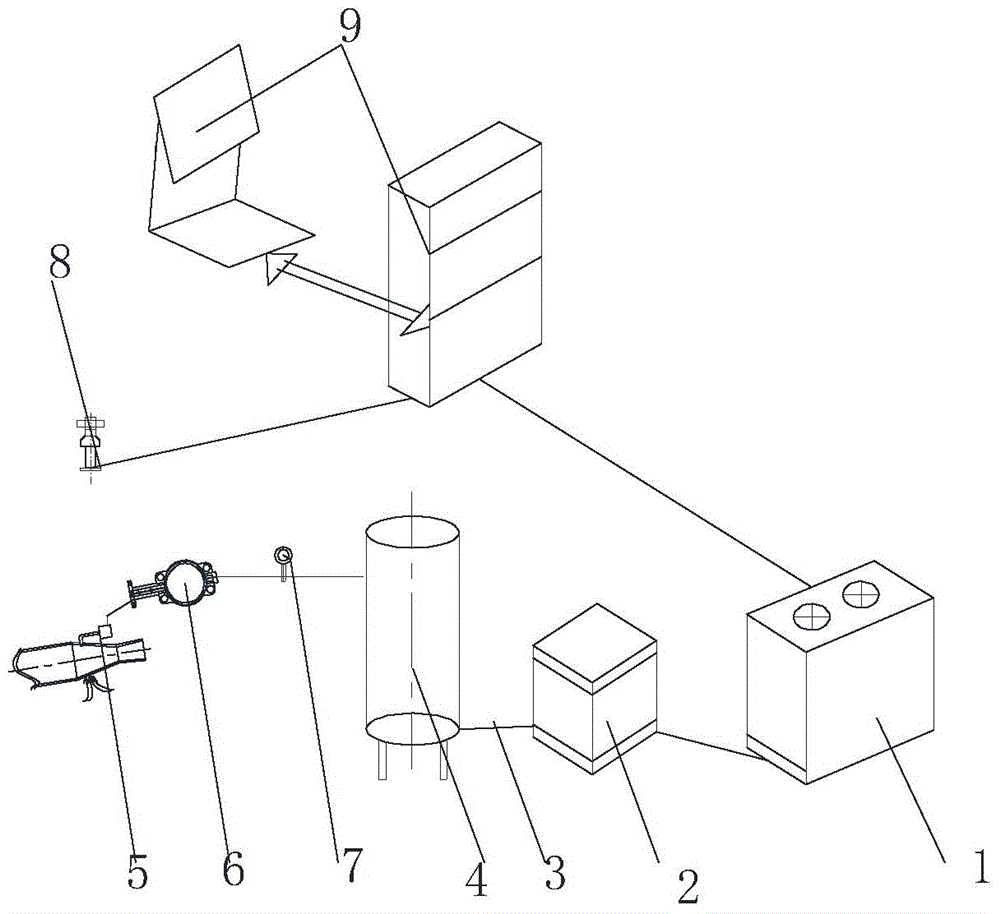

Energy-saving large casting cooling device

The invention relates to an energy-saving large casting cooling device comprising an air compressor 1, a cooling dryer 2, a compressed air pipeline 3, an air storage tank 4, a venturi blower 5, a pressure adjusting valve 6, a pneumatic control valve 7, a temperature transmitter 8 and an electric control system 9. The device is characterized in that the venturi blower 5 produces large air flow to cool large castings. The device has the advantages that the relevant component action relevance of the system controlling process is implemented, and actions are executed automatically; the venturi blower serves as a cooling device, compressed air is saved greatly, and operation cost is reduced.

Owner:NINGXIA JIAXIANG AUTOMATIC CONTROL TECH

Compression dressing device for breast surgery

InactiveCN103431949BSave compressed airGuaranteed pressure effectBreast bandagesAbdomen bandagesRight breastAtmospheric pressure

The invention discloses a pressure dressing device for breast surgery. The pressure dressing device for breast surgery comprises a waistcoat type body and hemispheric air bags which are arranged on the body and can cover left and right breasts respectively, wherein each air bag is composed of a plurality of inflating units which are not communicated with one another, and each inflating unit is provided with an inflating inlet; as each air bag is divided into a plurality of units, the inflating unit corresponding to a wound can be inflated independently, thus the compressed air is saved and the pressurizing effect can be ensured; in addition, a rigid interlayer is arranged on the outer surface of each air bag, so that the air pressure in the air bag is ensured to be applied to the wound position and the pressurizing effect is better.

Owner:THE FIRST AFFILIATED HOSPITAL OF THIRD MILITARY MEDICAL UNIVERSITY OF PLA

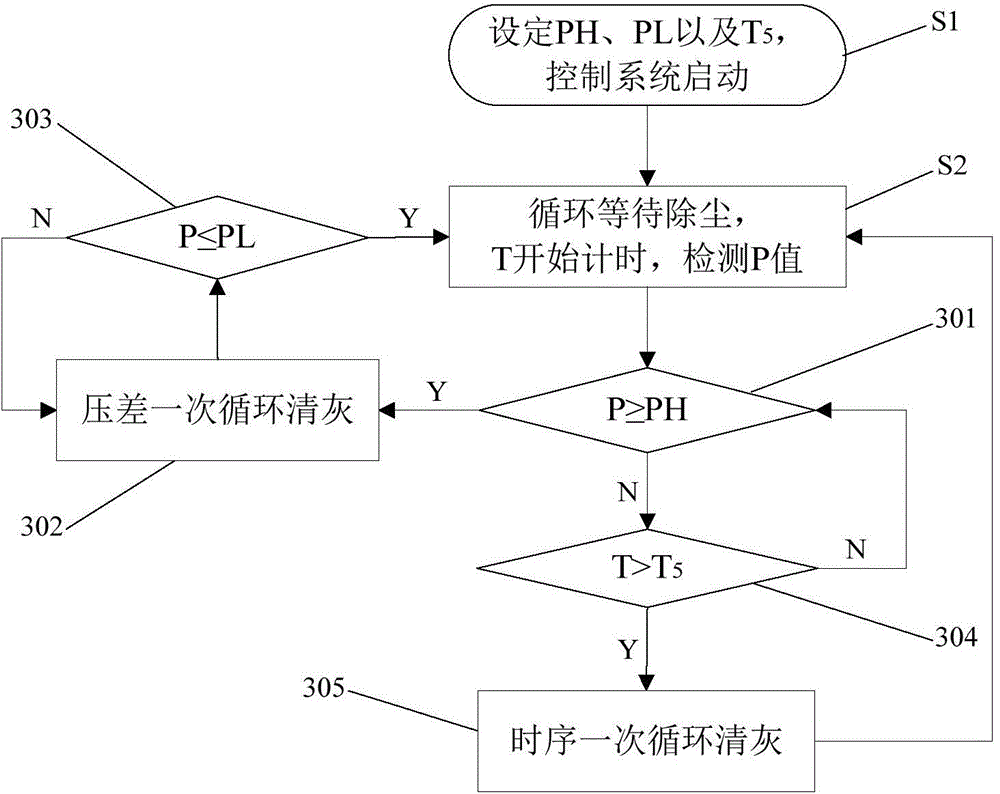

A differential pressure time-sequential mixing control method for a bag filter

InactiveCN105688531BSave compressed airAdjust working densityDispersed particle filtrationLower limitDifferential pressure

The invention relates to a pressure difference-timing sequence mixed control method for a bag type dust collector. The method includes S1) a step of setting pressure difference dust collecting work conditions comprising a pressure difference upper limit value PH and a pressure difference lower limit value PL with the PL being less than the PH, and setting timing sequence dust collecting work conditions comprising a timing sequence cycling time T5, S2) a step of circulating dust collecting wait, allowing a timer T to be started from zero and detecting the pressure difference P between upper and lower boxes of the dust collector, and S3) a step of, when the pressure difference P reaches the pressure difference upper limit value PH, controlling Q electromagnetic pulse valves to perform a plurality of times of circulated dust clearing under work parameters for pressure difference dust collecting until the pressure difference P is not more than the pressure difference lower limit value PL, and returning to the step (S2); and when the pressure difference P does not reach the pressure difference upper limit value PH and the T from the timer is larger than the timing sequence cycling time T5, controlling the Q electromagnetic pulse valves to perform one time of circulated dust clearing under work parameters for timing sequence dust collecting, and returning to the step (S2). Compared with the prior art, the method is advantaged by being capable of pressure difference control, energy-saving and efficient, and the method can improve stability of circulated dust clearing for the bag type dust collector and can prolong the overall lifetime of filter bags.

Owner:上海袋式除尘配件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com