Pulse bag type dust collector device

A bag-type dust collector and pulse technology, applied in the field of industrial flue gas dust collector devices, can solve the problems of the reduction of air volume of the dust collector dust removal system, the reduction of the efficiency of the dust collector, and the inability to destroy the primary layer, so as to ensure the sealing performance, flexible use, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

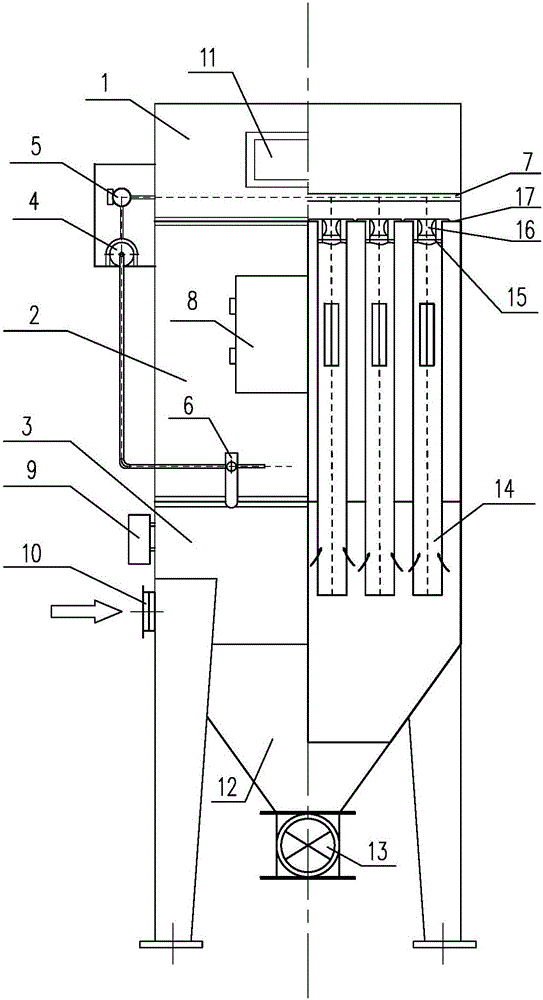

[0017] Such as figure 1 As shown, the embodiments of the present invention are as follows:

[0018] The pulse bag dust collector device provided by the present invention includes an upper box body 1, a middle box body 2, a lower box body 3, an ash hopper 12, a dust removal mechanism and an ash cleaning mechanism, wherein the ash hopper is connected to the lower end of the lower box body. The upper box body is provided with an air outlet 11, the inner cavity of the upper box body is a clean air chamber, the lower box body is provided with an air inlet 10, and the inner cavity connecting the middle box body and the lower box body is a filter chamber. The dust removal mechanism is located in the filter chamber, the original flue gas enters the filter chamber from the air inlet and upwards, and the dust removal mechanism realizes filtering and dust removal. The clean flue gas after filtering and dust removal passes through the clean air chamber and is discharged from the air outlet. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com