Mould-proof isolation powder pretreatment device and method for glass film plating production line

A technology of a coating production line and a pretreatment device, which is applied in the direction of cleaning methods using tools, cleaning methods using gas flow, chemical instruments and methods, etc., and can solve problems such as secondary pollution, easy adhesion to cleaning machine rollers, defects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

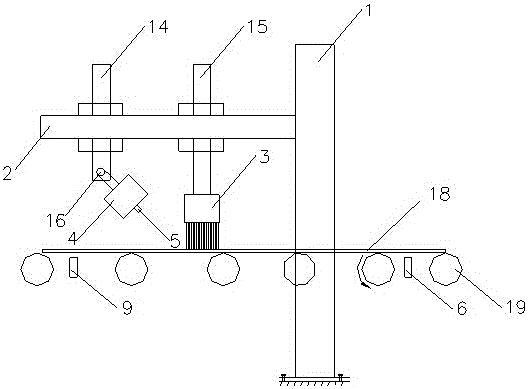

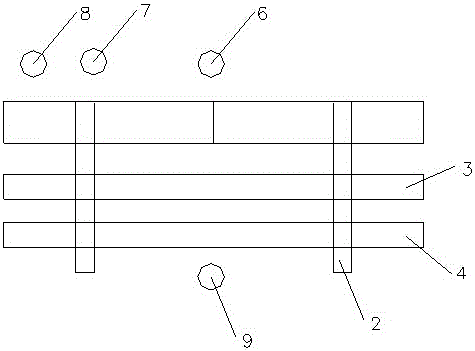

[0029] Such as figure 1 As shown, the anti-mold isolation powder pretreatment device for the glass coating production line of the present invention includes a roller table 19, a column 1 and a main support 2, and the column 1 is vertically fixed on the glass conveying roller table of the glass coating line or on the ground, and the main The right end of the bracket 2 is transversely connected to the upper left side of the column 1 . The roller table 19 is laterally located in the middle of the column 1, and the roller table 19 drives the glass 18 to move from right to left.

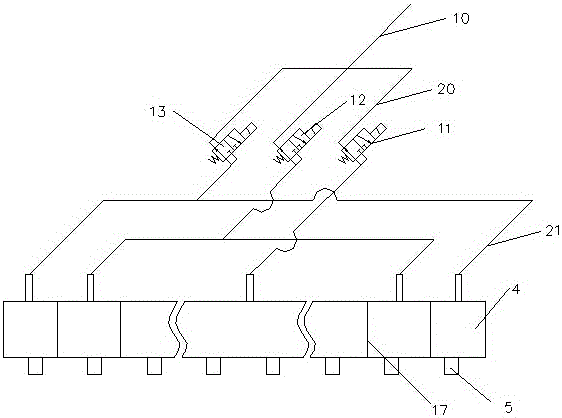

[0030] The main support 2 is connected with a brush support 15 and an air-collecting pipe support 14 successively from right to left. Adjust the angle between the jet stream and the glass surface. The hairbrush 3 and the gas collecting pipe 4 are respectively suspended above the roller table 19 along the traveling direction of the glass 18 through the brush bracket 15 and the gas collecting pipe bracket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com