Vacuum generating device of wafer chuck

A technology of vacuum generating device and vacuum generator, which is applied in the manufacture of electrical components, semiconductor/solid state devices, circuits, etc., can solve the problems of waste of compressed air and increase of production cost, so as to improve economic benefits, save production costs, and save compression air effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

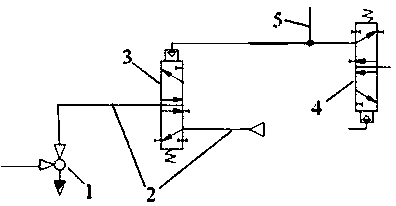

[0011] Such as figure 1 As shown, a vacuum generating device for a wafer chuck includes: a vacuum generator 1 connected through pipelines, a compressed air pipeline 2 and a gas valve 3 . Wherein, the vacuum generator 1 provides vacuum to the wafer chuck; the gas valve 3 is arranged on the compressed air pipeline 2, and the control end of the gas valve 3 is connected to the gas supply pipeline 5 of the working valve 4 of the external wafer chuck through the pipeline.

[0012] When working, the gas supply pipeline 5 provides compressed air to the working valve 4, so that the wafer chuck starts to work, and at the same time, part of the compressed air from the gas supply pipeline 5 enters the control end of the gas valve 3, thereby leading the gas valve 3, with Input compressed air to the vacuum generator 1, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com