Automatic adjustable dragging method pipe

A technology of adjustable and drawn tubes, applied in the direction of engine components, lifting valves, valve details, etc., can solve the problems affecting the working efficiency and batching accuracy of the pneumatic conveying system, and the large fluctuation of working pressure, so as to save compressed air and materials The effect of improving the flow capacity and reducing the influence of airflow stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

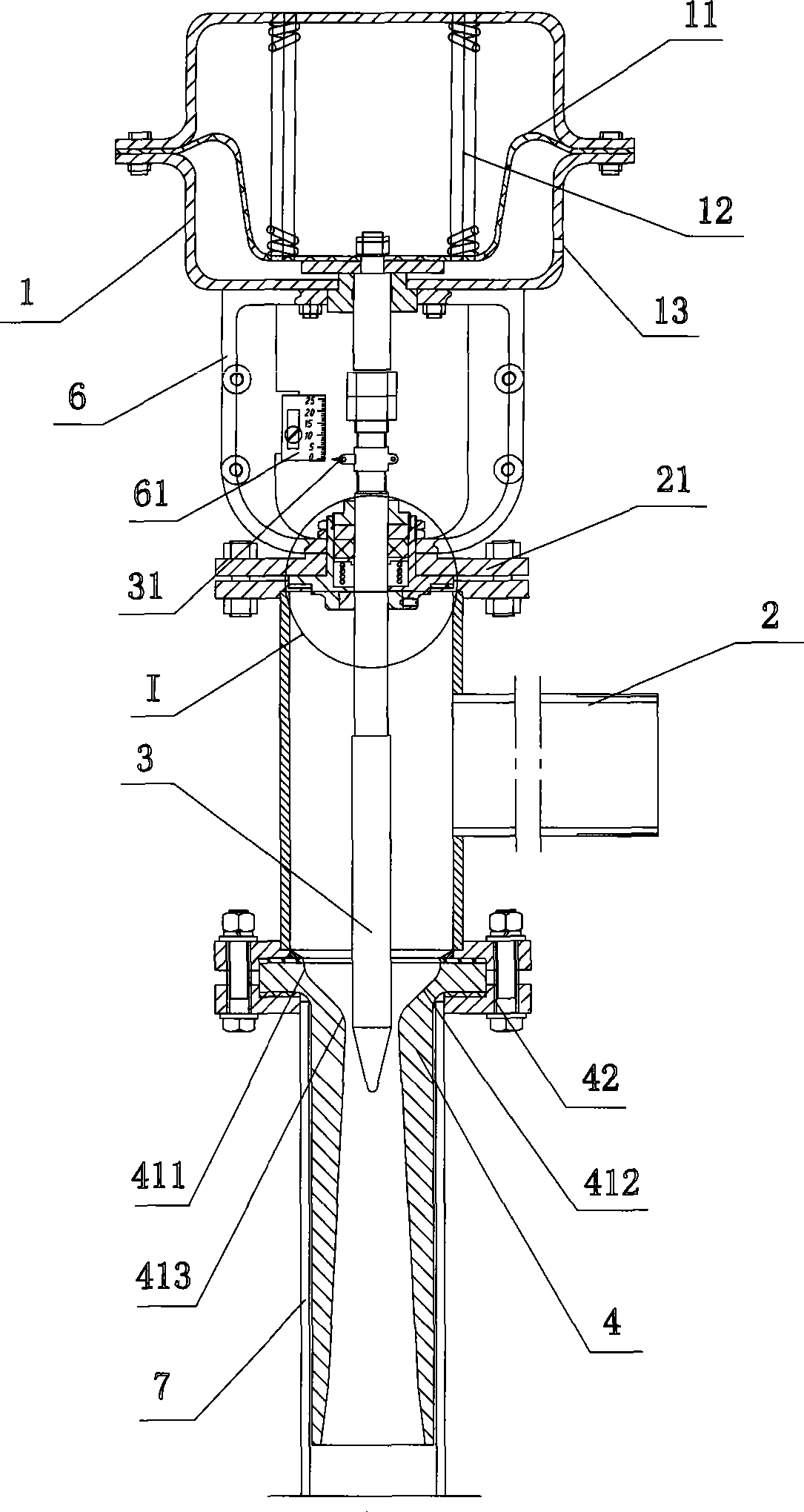

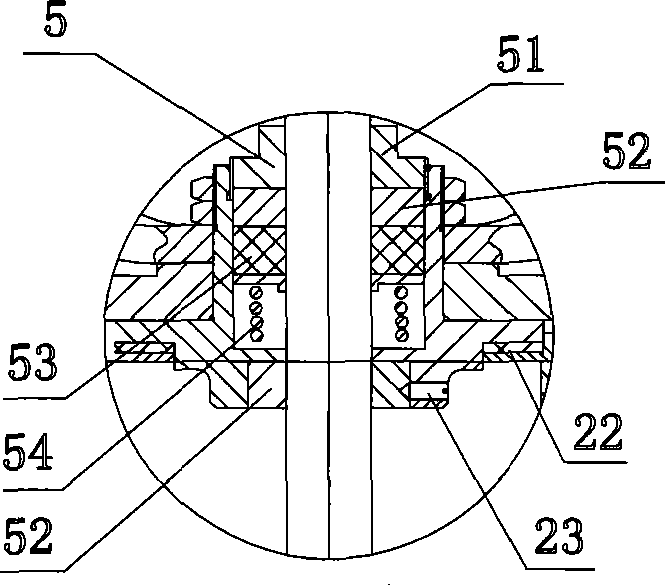

[0035] Example 1, such as Figure 1 to Figure 3 As shown, the automatic adjustable puller tube includes an automatic pressure regulator 1 , an air inlet pipe 2 , an adjustment rod 3 , a fixed puller tube 4 , a sealing disc 5 , a dial 6 and an air tube 7 . in,

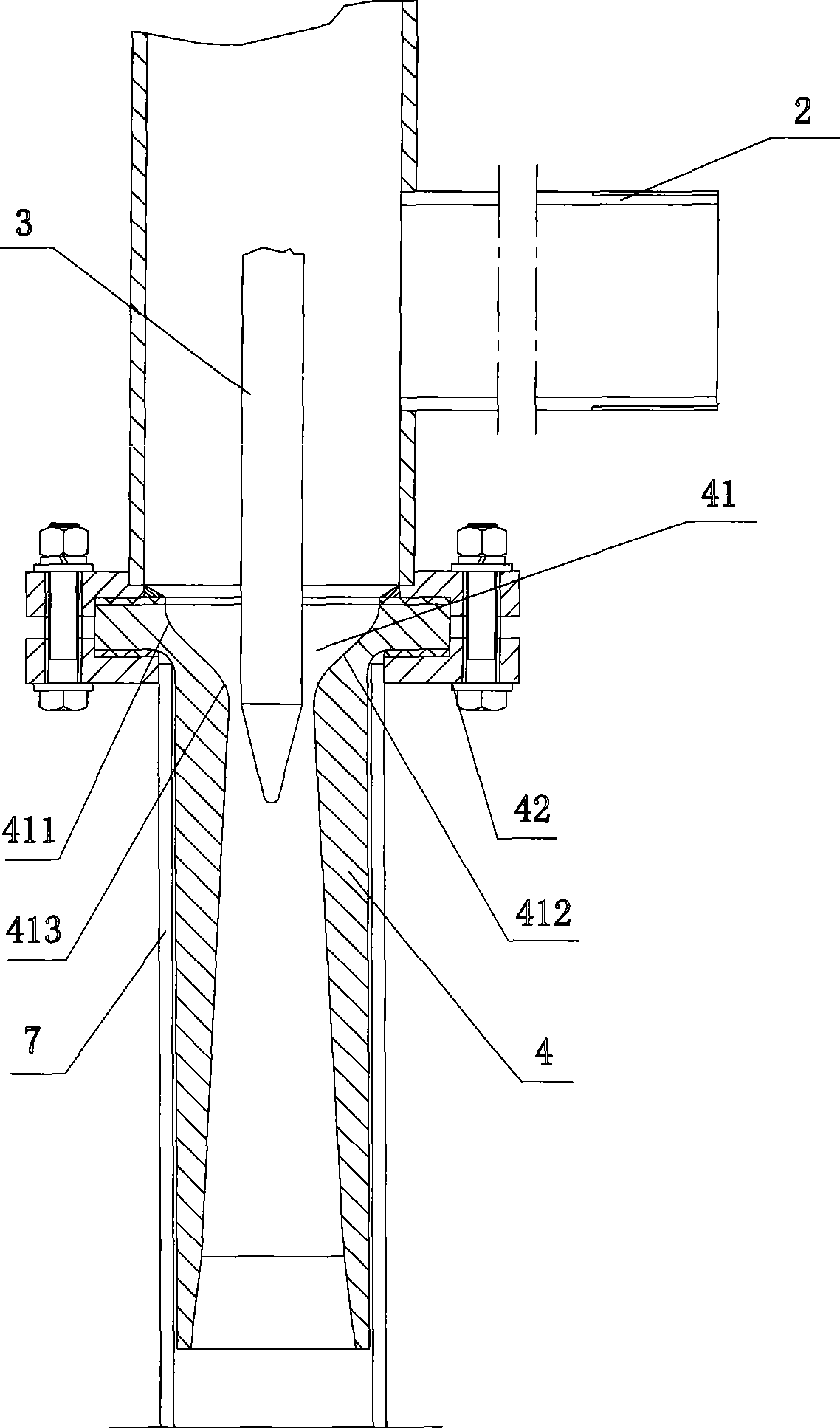

[0036] An air pipe 7 is sheathed outside the fixed puller pipe 4 .

[0037] The intake pipe 2 and the fixed Laf pipe 4 are fixedly connected to each other through flanges and bolts 42 .

[0038] The adjusting rod 3 runs through the air intake pipe 2, its outer end is connected to the automatic pressure regulator 1, and its inner end extends into the entrance 41 of the fixed puller pipe 4, and the end of the adjusting rod 3 is set to be tapered .

[0039] The section at the entrance 41 has a funnel-shaped curve structure, the curve 411 is a section of arc whose center is on the inlet interface of the fixed drawing pipe 4, and the curve 413 is the minimum cross section of the throat of the fixed drawing pipe 4 Curve 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com