Material picking device

A material and feeding technology, applied in the field of flat cylindrical material selection device, can solve the problems of increased production cost, time-consuming manual picking, and increased worker workload, etc., and achieves centralized material placement, easy management, and saving compression. effect of air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

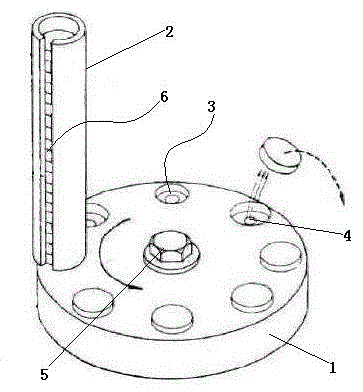

[0022] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

[0023] like figure 1 As shown, a material selection device includes: a turntable 1 and a supply cylinder 2 . Several counterbores 3 are set on the turntable 1, and several counterbores 3 are concentrically distributed on the upper surface of the turntable 1, and the bottom of the counterbore 3 is provided with an air hole 4, and the center of the turntable 1 is fixedly connected to the rotating shaft 5, and the feeding cylinder 2 It is a cylindrical structure with grooves at both ends, and the lower outlet of the supply cylinder 2 is facing the counterbore 3.

[0024] By adopting the matching structure of the turntable 1 and the supply barre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com