Coking wastewater treatment process and coking wastewater treatment equipment

A technology of coking wastewater and treatment equipment, which is applied in the direction of flotation water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., which can solve the problems of high operating costs, large-scale biological treatment facilities, High investment costs and other issues, to achieve the effect of reducing investment and floor area, shortening denitrification time, and reducing production and operation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

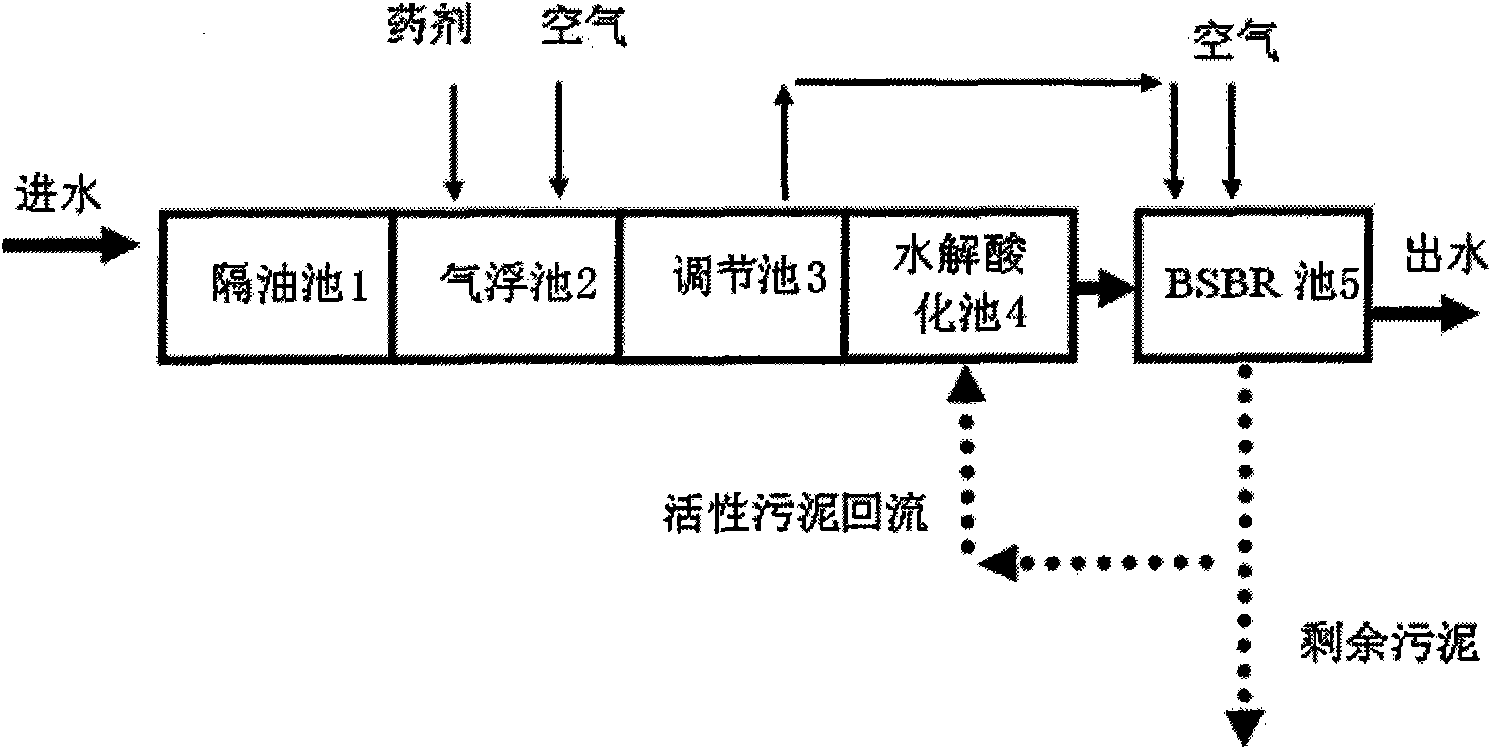

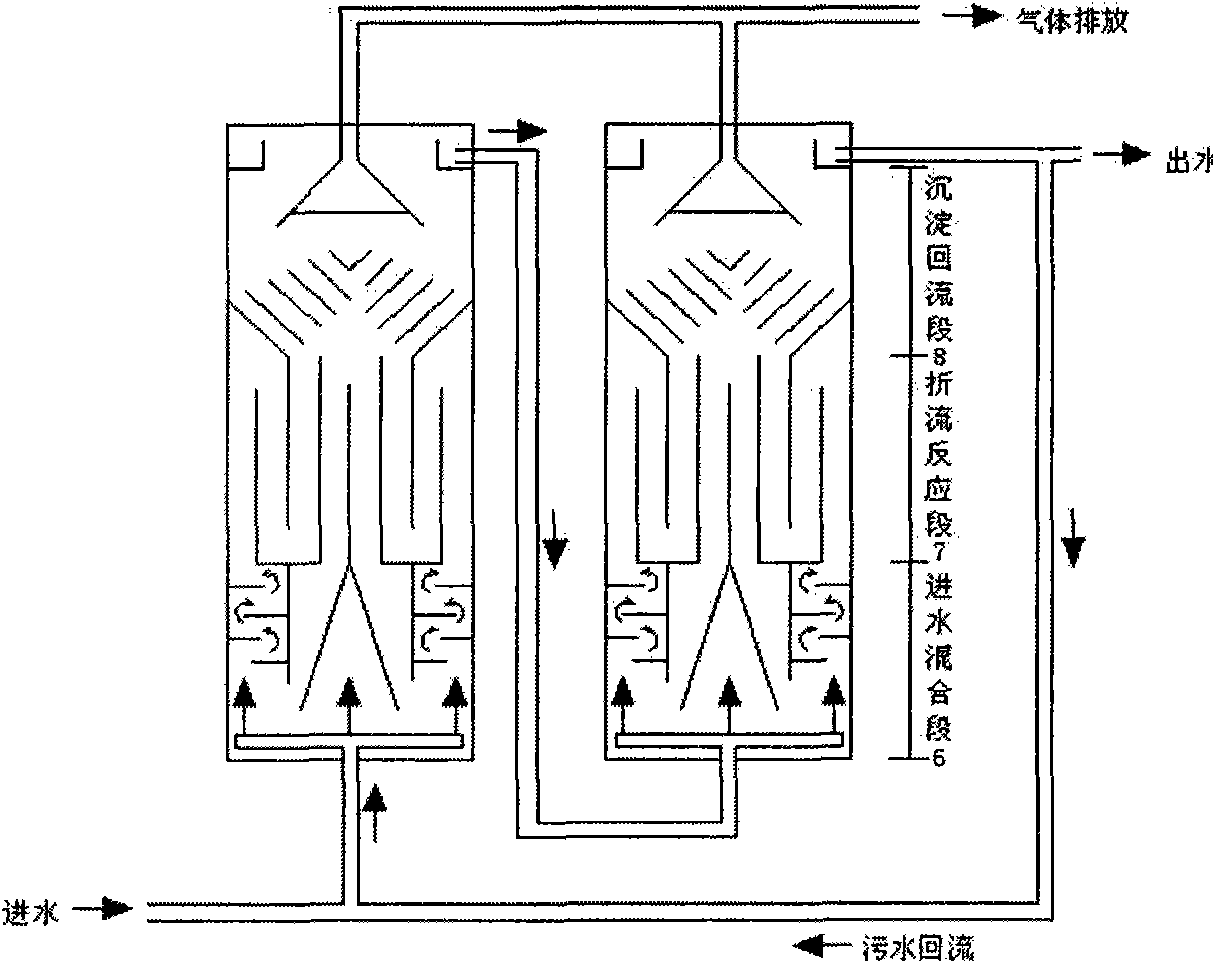

[0031] Such as figure 1 A kind of coking wastewater treatment equipment is shown: it mainly includes grease trap 1, air flotation tank 2, regulating tank 3, hydrolysis acidification tank 4, BSBR tank 5, as well as pipelines connecting the above units, valves and infusion pumps installed on the pipelines and a control unit; the BSBR reaction tank is fixedly filled with elastic three-dimensional packing; the sludge in the BSBR tank 5 is returned to the hydrolysis acidification tank 4 .

[0032] A coking wastewater treatment process: the wastewater is discharged into the advection grease trap 1 through the sewage pipeline to remove the slick oil on the surface, and then enters the air flotation system to remove emulsified tar and part of COD and BOD, and the effluent flows into the regulating tank to balance the water quality and quantity. Then enter the up-flow hydrolysis acidification pool 4 to convert the refractory polycyclic aromatic hydrocarbons and heterocyclic compounds i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com