Turbine type gas magnetic engine

An engine and turbine-type technology, applied in the field of turbo-type aeromagnetic motors, can solve the problems of low output power, low efficiency, and large gas consumption, and achieve the effect of reducing compressed air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below.

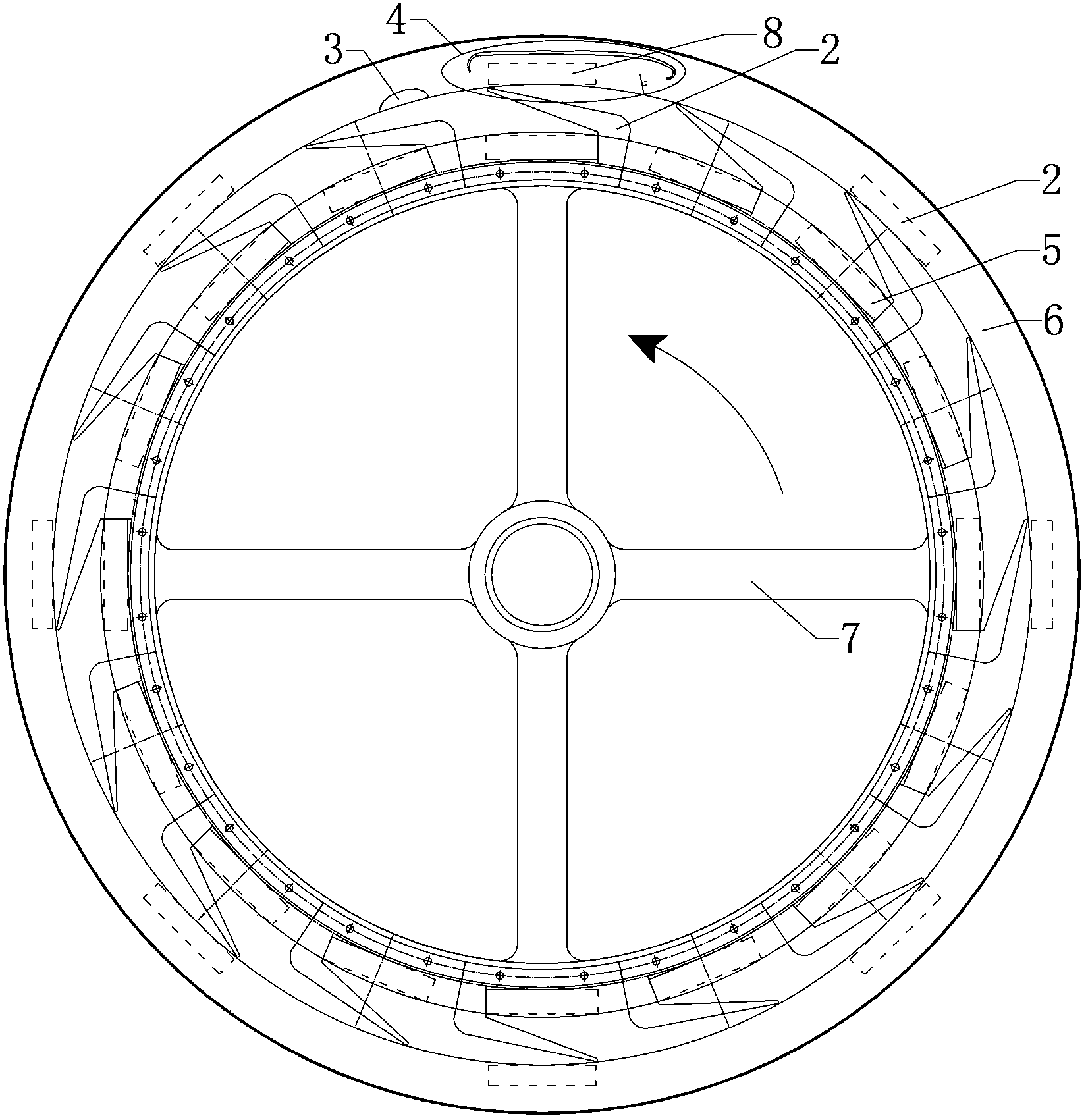

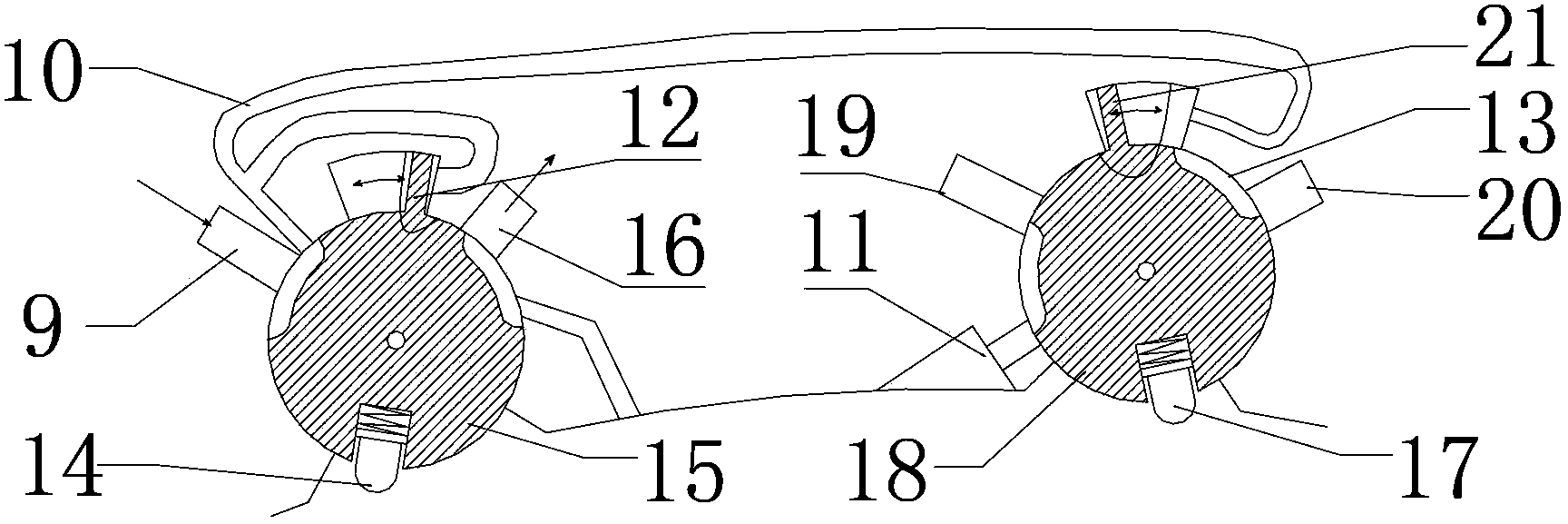

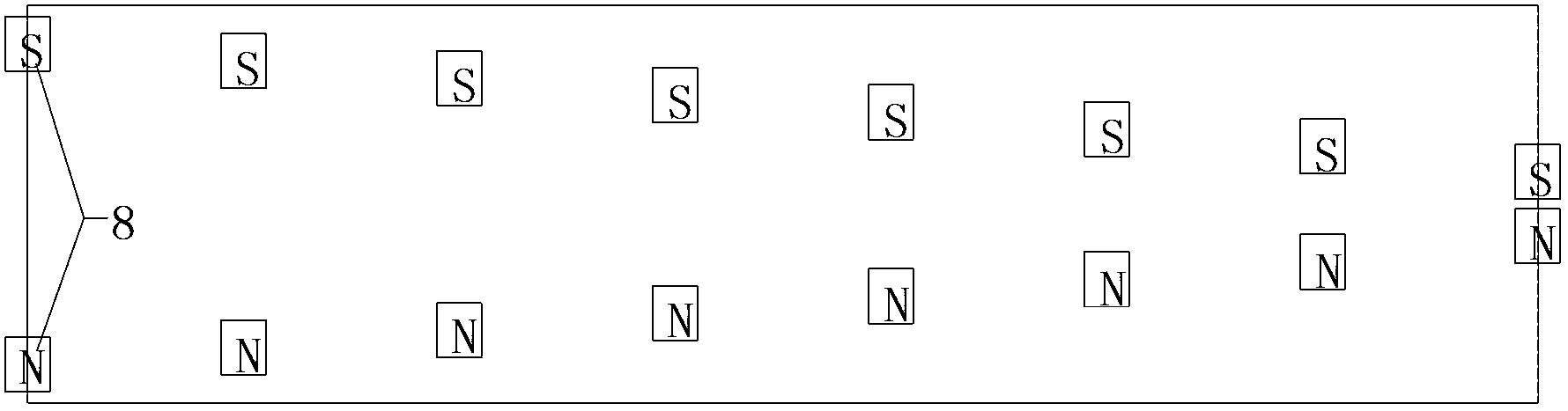

[0016] Install permanent magnets on the stator and rotor respectively with opposite magnetic poles, 16 pieces of "U"-shaped magnetic isolation plate blades (2) are embedded on the rotor, and the rotor permanent magnets (5) are embedded in the "U"-shaped magnetic isolation plate blades (2) A set of air distribution mechanism (4) is installed on the inner edge of the stator to provide pulse air supply, the angle between the outlet direction of the air injection port (11) and the radial direction is the same as the angle between the outer edge of the magnetic isolation plate blade (2) and the radial direction the same angle;

[0017] When any rotor permanent magnet (5) on the rotor (7) is located at the right end position of the corresponding stator permanent magnet (1), the rotor permanent magnet (5) will be subjected to counterclockwise suction; When the magnet (5) is located in the middle of the stator permanent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com