Inside-mixing atomizing nozzle device

An atomizing nozzle and internal mixing technology, applied in the direction of spray device, liquid spray device, etc., can solve the problems of poor fluidity, high solid content, high viscosity, affecting the application of atomization technology, etc., to enhance the effect of airflow atomization, The effect of saving compressed air and large material through holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

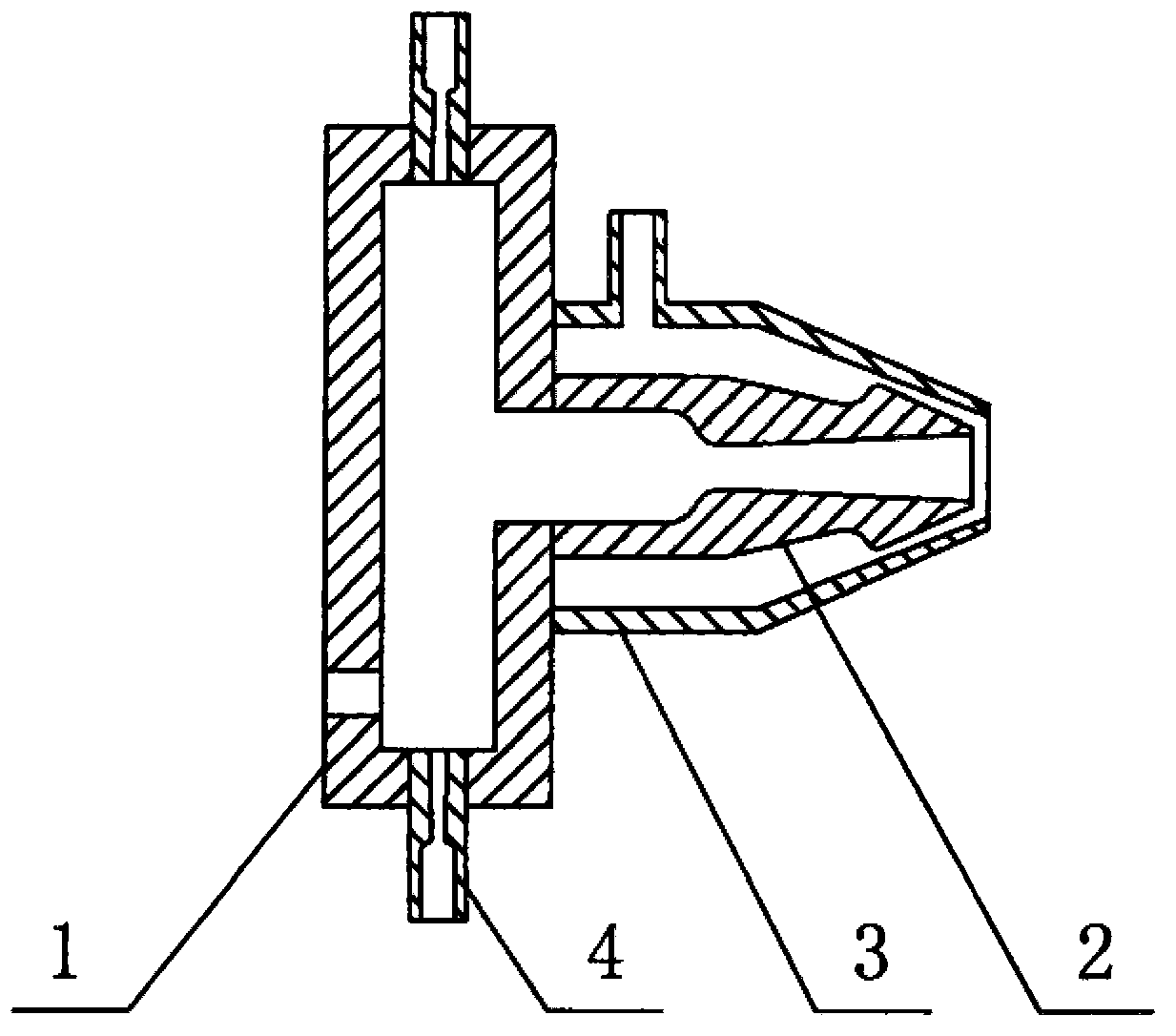

[0019] The structure of the internal mixing atomizing nozzle device of the present invention will be described with reference to the drawings and embodiments.

[0020] The structure of the internal mixing atomizing nozzle device of the present invention is: the nozzle device includes a mixing chamber 1, and an air inlet pipe 4 is provided on the side wall of the mixing chamber 1; An air flow cover 3 is sheathed on the outside of the tube 2 . The outer surface of the injection pipe 2 and the inner surface of the airflow cover 3 form a high-speed airflow chamber, and the outlet of the airflow cover 3 is in the same direction as the outlet of the injection pipe 2 and slightly exceeds the outlet of the injection pipe 2, forming an annular outlet of the airflow chamber that shrinks towards the center. The other end of the airflow cover 3 is provided with an inlet to connect compressed air. The air intake direction of the airflow cover 3 enters in a tangential direction opposite to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com