Oil-gas two-phase jet-type lubricating and cooling system

A lubricating cooling, jet-type technology, applied in the direction of heating/cooling equipment, manufacturing tools, forging/pressing/hammer devices, etc., can solve the problems of polluting the factory environment, harmful to human body, etc., achieve strong permeability, sufficient cooling, and reduce consumption volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

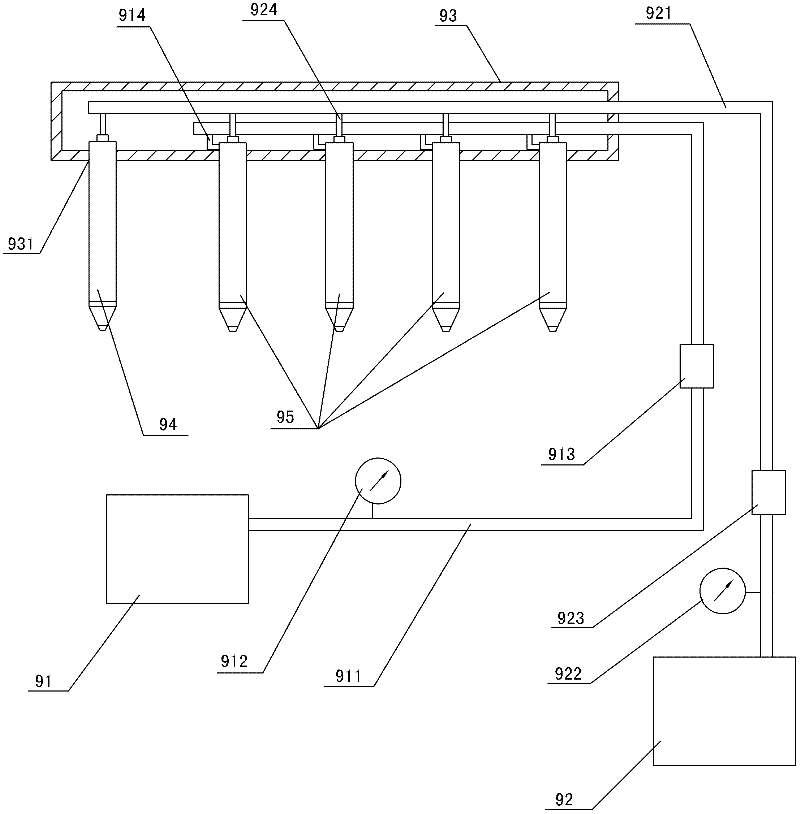

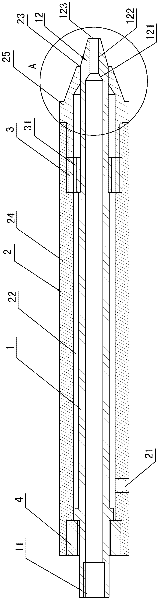

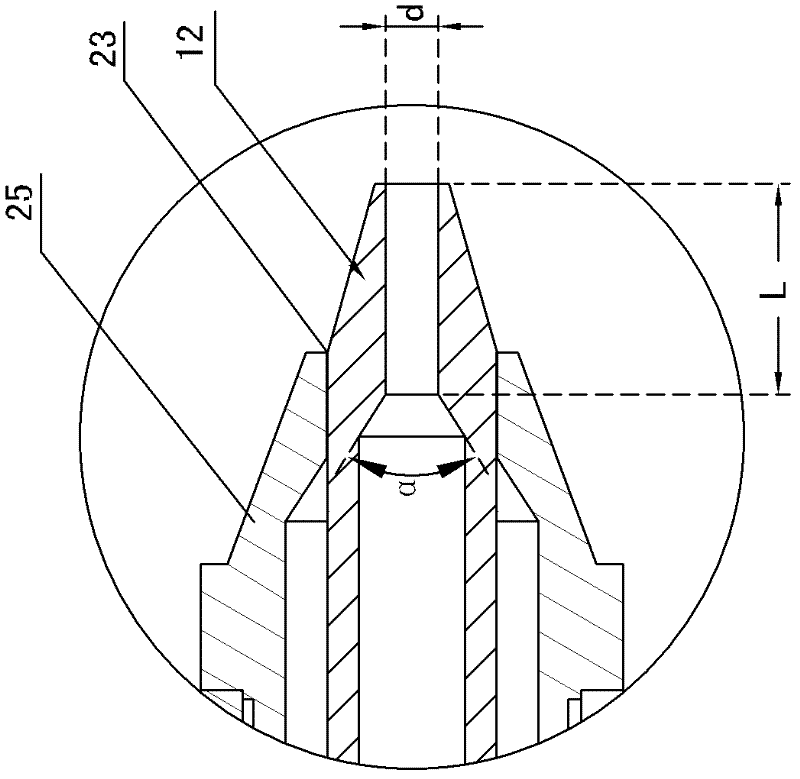

[0021] The present invention proposes an oil-air two-phase jet lubrication and cooling system for multi-station automatic cold heading machines, such as figure 1 , figure 2 and image 3 As shown, it includes a pressure gas supply device 91, a pressure oil supply device 92, an air oil pipe frame 93, a pure oil nozzle 94 for lubricating and cooling the cut-off station of a multi-station automatic cold heading machine, and N pieces for lubricating and cooling N forming stations of the multi-station automatic cold heading machine (generally, the forming stations of the multi-station automatic cold heading machine include initial heading forging station, one-time forming station, modification station and final forming station 4) The air-oil nozzle 95, the pressure gas supply device 91 is connected with an air flow pipeline 911, and the air flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com