Crust breaking cylinder air throttle and testing device and testing method

A technology of shelling cylinder and testing device, applied in the field of throttle valve and its testing device, can solve the problems of large consumption and waste of compressed air, and achieve the effect of high gas consumption efficiency, saving compressed air and improving gas consumption efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

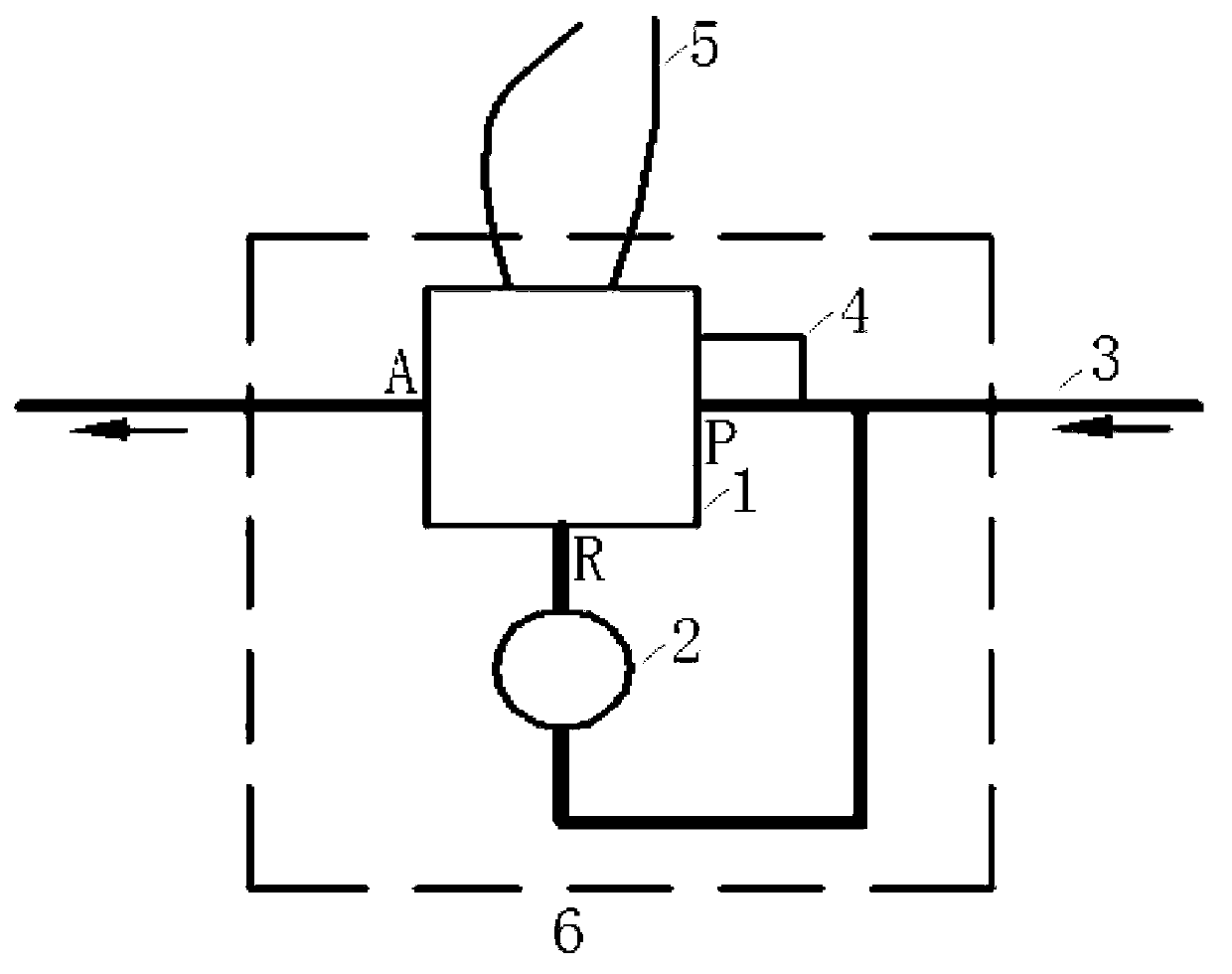

[0022] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

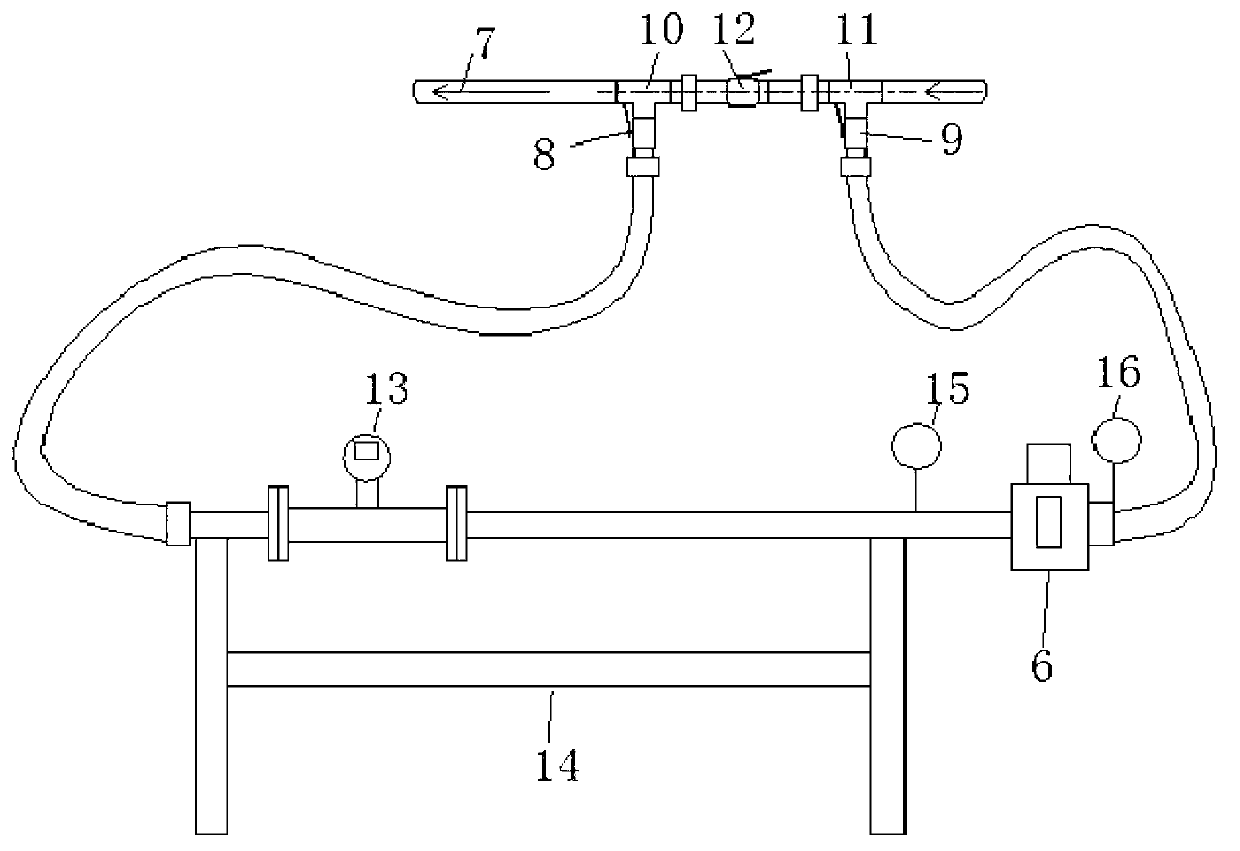

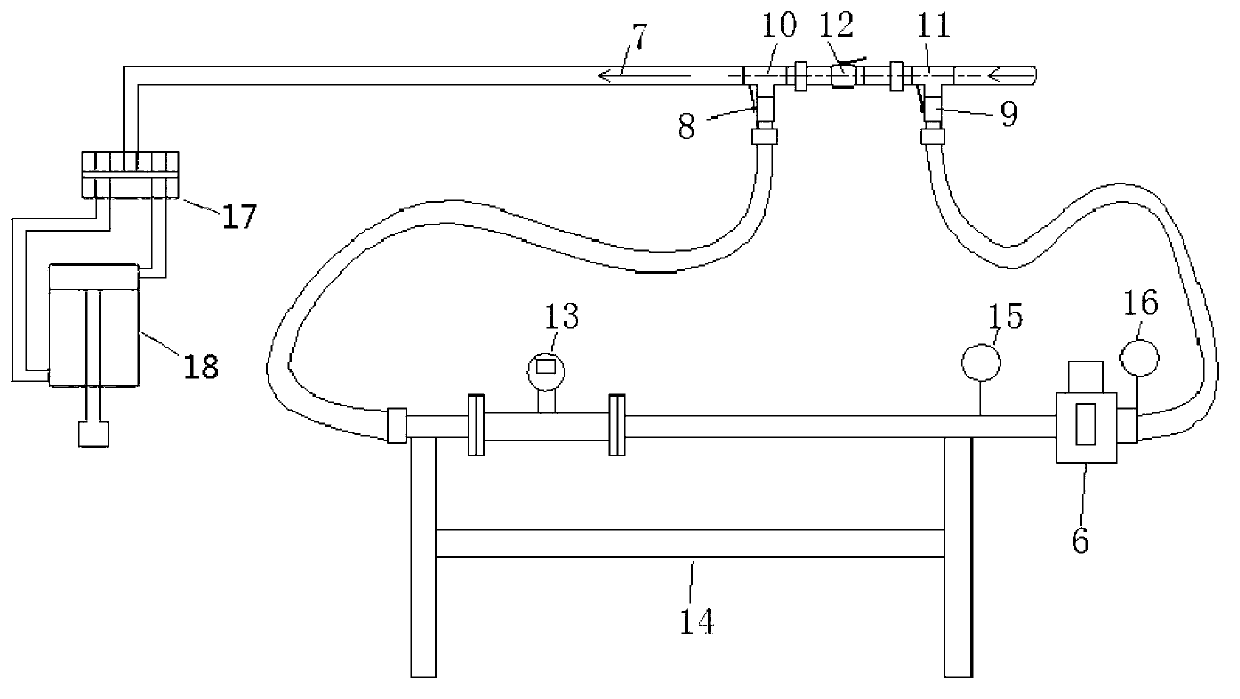

[0023] figure 1 The throttle valve 6 of the shelling cylinder includes a pressure regulating valve 2, an air supply pipe 3, an external pilot pipe 4, a two-position three-way solenoid valve 1 and a corresponding two-position three-way solenoid valve power supply control line 5. Valve 6 is installed on each electrolyzer shelling cylinder 18 air supply branch pipes, and the control signal of shelling cylinder throttle valve 6 is an electric signal. The two-position three-way solenoid valve 1 is respectively provided with a P hole, an A hole and an R hole, and one end of the two-position three-way solenoid valve 1 is connected with the power supply control line 5 of the two-position three-way solenoid valve; the air supply pipe 3 includes an intake pipe and Outlet pipe, the inlet pipe of the air supply pipe 3 is connected with the P hole of the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com