Paintball gun with rearwardly removable pneumatic assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036]Various preferred aspects of the present invention will now be described in detail with reference to the accompanying figures. It should be noted, however, that the following description is provided by way of example only and not of limitation, and that many other implementations and embodiments of the present invention will be readily apparent to those skilled in the art based on the disclosure herein. The scope of the invention is therefore not limited to the particular embodiments described herein.

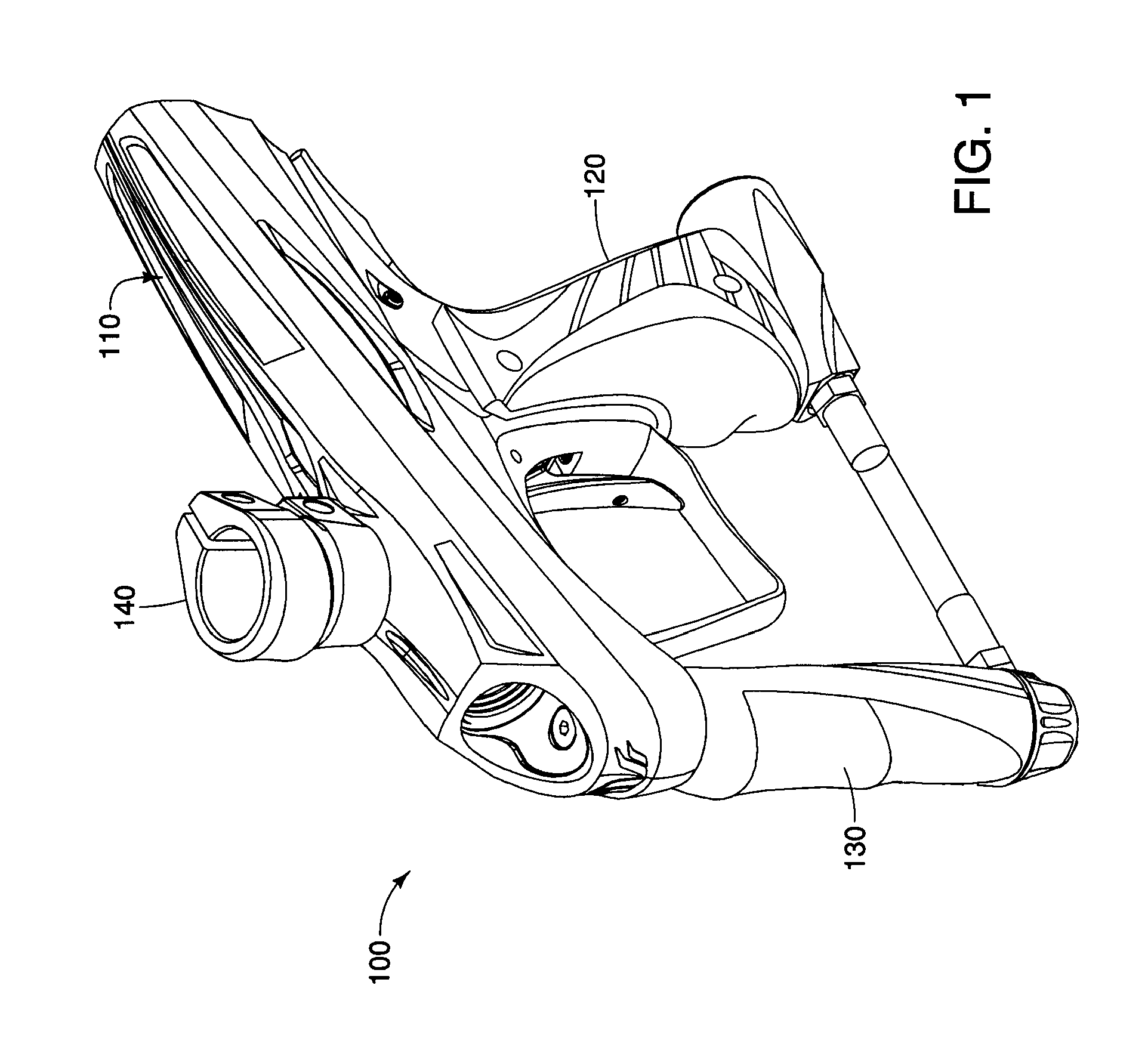

[0037]FIG. 1 is a somewhat schematic perspective view of a paintball gun 100 having a rearwardly removable pneumatic assembly according to principles of the present invention. Referring to FIG. 1, the paintball gun 100 includes a body 110 having a grip frame 120 and receiving a pneumatic regulator 130 and a feedneck 140. The body 110 is also configured to receive a barrel (not shown) into the breech of the paintball gun 100.

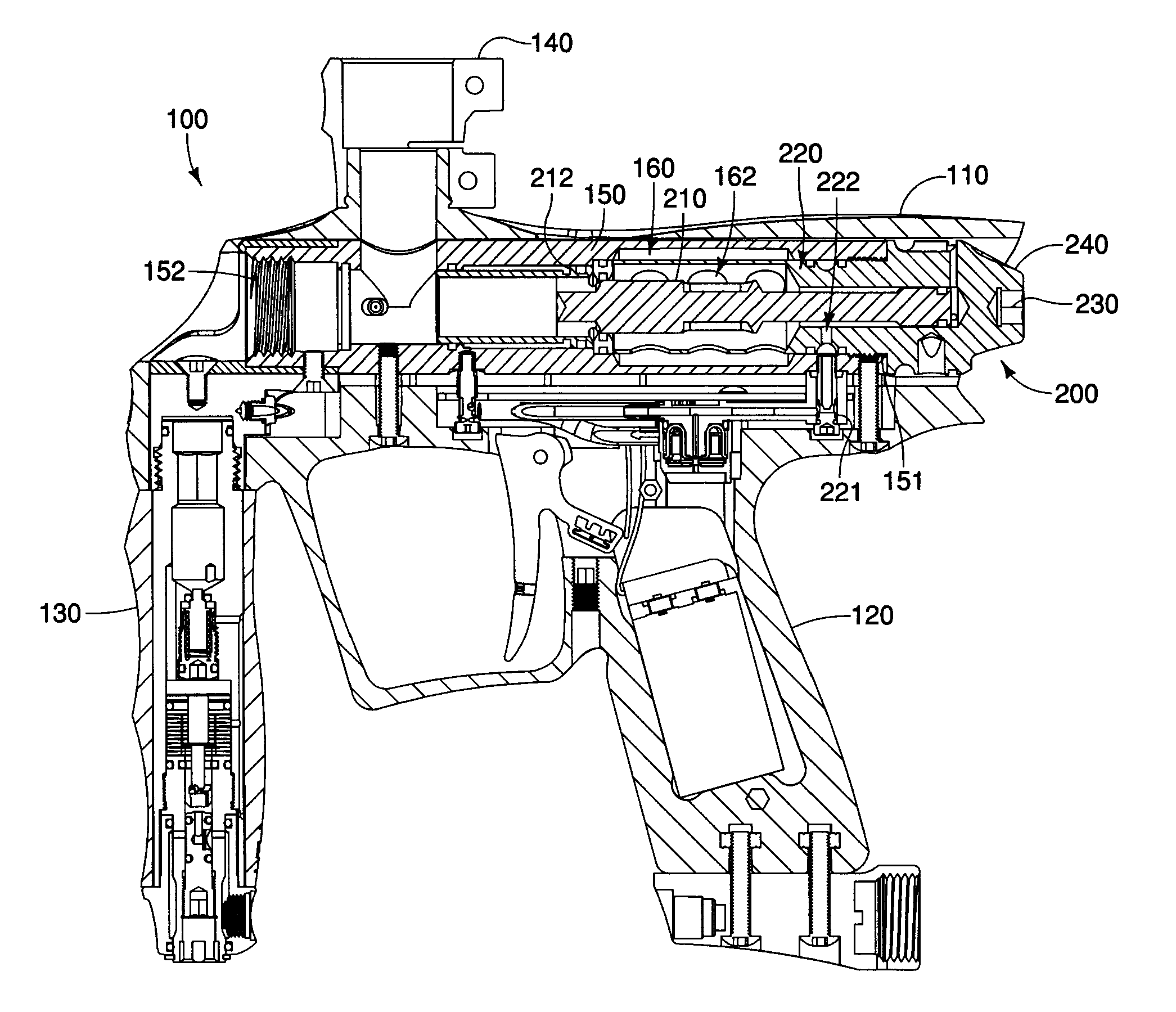

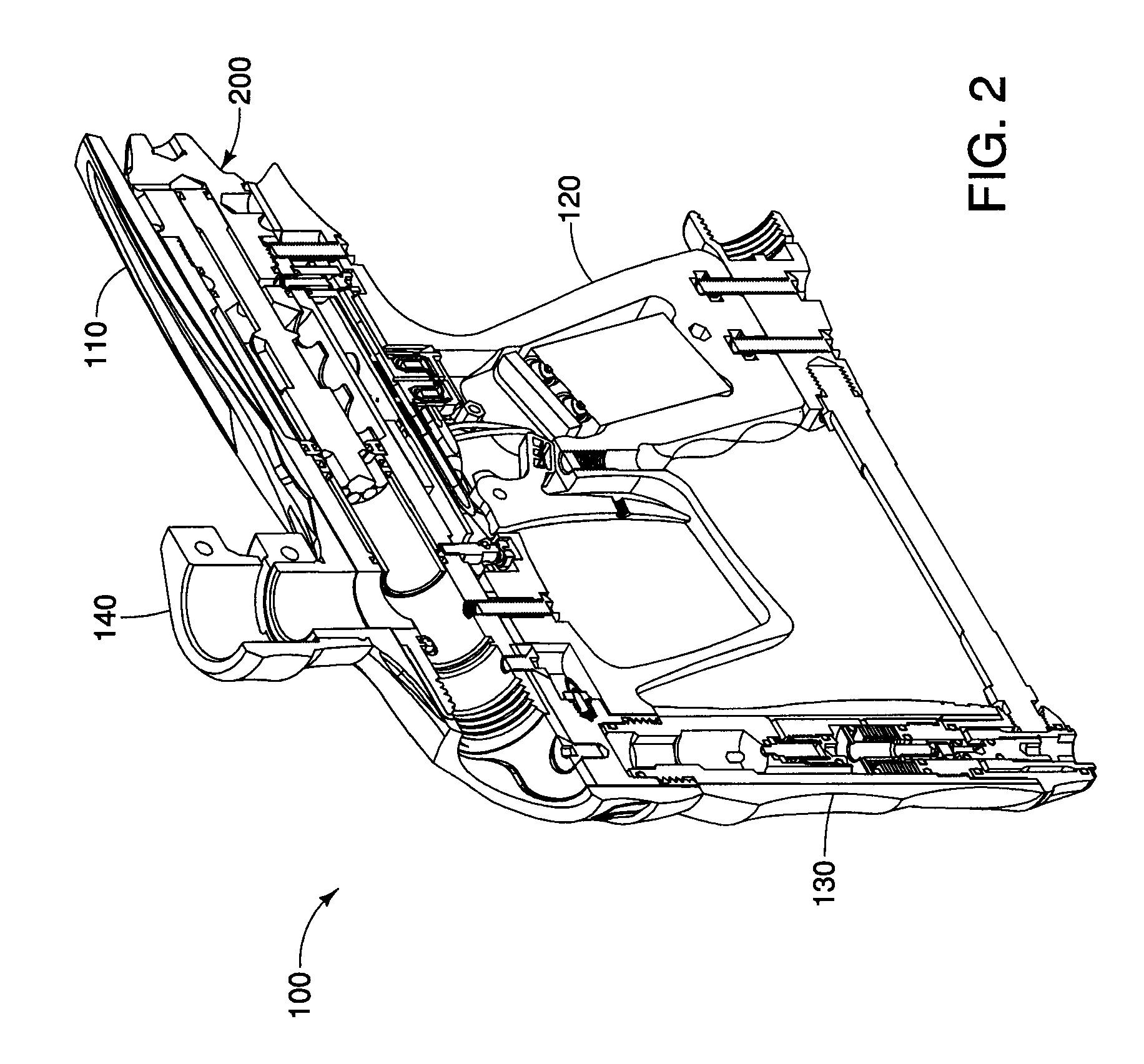

[0038]FIGS. 2 and 3 are somewhat schematic cross-sectiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com