Automatic electrical control system of pneumatic wheat conveying system

A technology of electric automatic control and pneumatic conveying system, which is applied to conveyors, conveying bulk materials, transportation and packaging, etc. It can solve the problems of blocked pipelines and easy formation of embolism, and achieves the goals of saving compressed air, reducing operating costs and optimizing control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

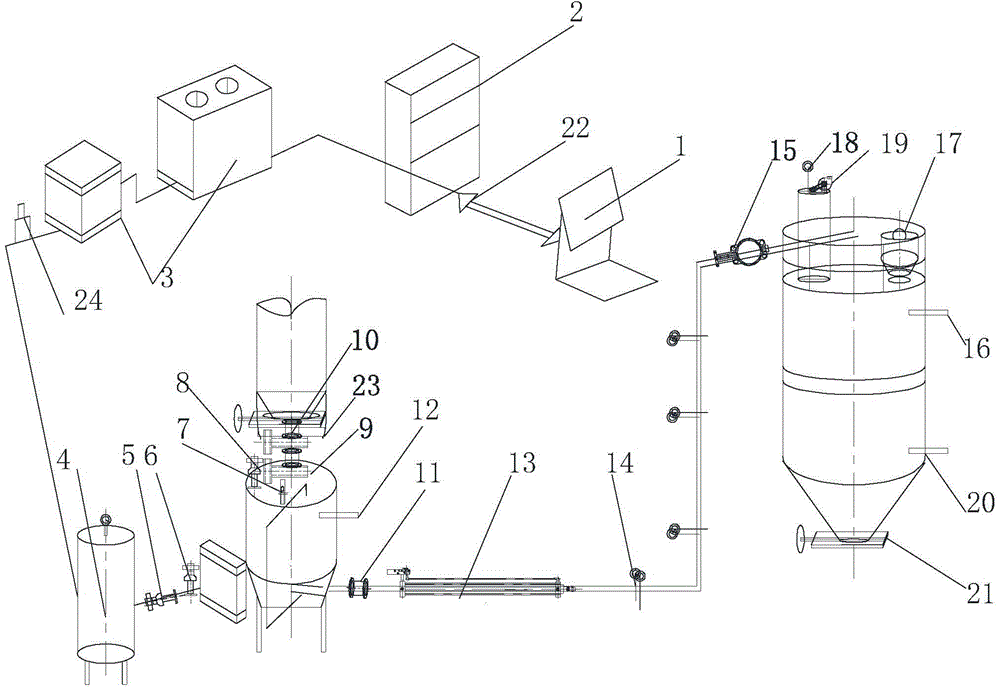

[0010] The composition and effect of the electric automatic control system of the pneumatic conveying system of a kind of wheat of embodiment 1:

[0011] Electrical automatic control system includes PLC programmable control system 1, industrial computer or DCS system 2, air compressor and freeze dryer motor 3, electric contact pressure gauge 4, pressure regulating valve 5, upper intake valve 6, pneumatic exhaust valve 7. Pressure transmitter 8, pneumatic feed valve 9, pneumatic pre-closing valve 10, pneumatic discharge valve 11, high level gauge 12, gas booster 13, pulse air knife valve 14, pneumatic switch valve 15, High-level material level gauge 16, pressure release valve 17, pulse valve for bag-type silo dust collector 18, pulse-back blow bag-type silo dust collector induced fan motor 19, low-level material level gauge 20, pneumatic flapper valve 21, Signal transmission cable 22, weighing sensor 23, mass flow meter 24, is characterized in that the electrical automatic cont...

Embodiment 2

[0012] The working process of the electric automatic control system of the pneumatic conveying system of a kind of embodiment 2 wheat:

[0013] The industrial computer or DCS system 2 uses the PLC programmable control system 1 to measure the data through the load cell 23 and the mass flow meter 24 according to the material-gas ratio, and adjusts the pressure of the gas coming out of the gas storage tank according to the ratio of the material-gas ratio of 20-22. The compressed air with the set pressure value of the valve 5 discharges the material added from the material hopper into the outlet of the warehouse pump through the pneumatic discharge valve 11, and transports it to the material pipeline, and is distributed into the warehouse by the pneumatic switching valve 15 according to the process and production needs. The high-level material level gauge 16 and the low-level material level gauge 20 are installed on the silo for controlling the material level of the silo. When th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com