Soaking method for high-purity graphite multi-immersed product

A high-purity graphite and product technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve problems such as inconsistent internal structure, troublesome graphite quality, and ineffective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

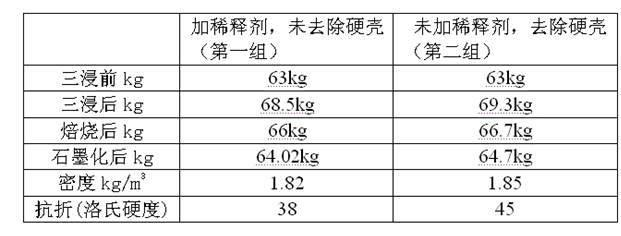

Examples

Embodiment 1

[0022] Put the roasted columnar carbon products on the disc, and automatically send them into the shot blasting chamber of the vertical disc shot blasting machine. Use high-pressure multi-directional spray iron shots to remove the 1 mm hard shell on the surface of the columnar carbon products, and then Weigh the carbon products with hard shells removed, put them into the iron basket and put them in the preheating furnace, preheat and keep them warm for 4.5 hours at 200°C; take out the preheated iron baskets, and put them into the impregnation tank within 15 minutes Medium; evacuate to -0.095MPA for 50 minutes; then add coal tar pitch at 180°C to the impregnation tank, keep it for 4.5 hours under the pressure of 1.5MPa, then hang out the iron basket within 15 minutes, put it in the temperature Cool in a cooling pool at 40°C for 3 hours, hang out and clean the asphalt on the surface, and then roast. During the roasting process, the temperature of the roasting is gradually raised ...

Embodiment 2

[0024] Put the roasted columnar carbon products on the disc, and automatically send them into the shot blasting chamber of the vertical disc shot blasting machine. Use high-pressure multi-directional spray iron shot to remove the 2 mm hard shell on the surface of the columnar carbon products, and then Weigh the carbon products with hard shells removed, put them into the iron basket and put them in the preheating furnace, preheat and keep them warm for 4.6 hours at 203°C; take out the preheated iron baskets, and put them into the impregnation tank within 15 minutes Medium; vacuumize to -0.095MPA in 53 minutes; then add coal tar pitch at 183°C to the dipping tank, keep it for 4.6 hours under the pressure of 1.6MPa, then hang out the iron basket within 15 minutes, put it in the temperature Cool in the cooling pool at 43°C for 3 hours, lift out the asphalt to clean the surface, impregnate and then roast, the temperature of roasting is gradually raised from room temperature to 550°C...

Embodiment 3

[0026] Put the roasted columnar carbon products on the disc, and automatically send them into the shot blasting chamber of the vertical disc shot blasting machine. Use high-pressure multi-directional spray iron shots to remove the 3 mm hard shell on the surface of the columnar carbon products, and then Weigh the carbon products with the hard shell removed and put them into the iron basket and put them in the preheating furnace, preheat and keep warm at 205°C for 4.7 hours; take out the preheated iron basket and put it into the impregnation tank within 15 minutes Medium; evacuate to -0.095MPA for 55 minutes; then add coal tar pitch at 185°C to the impregnation tank, keep it for 4.7 hours under the pressure of 1.7MPa, then hang out the iron basket within 15 minutes, put it in the temperature Cool in the cooling pool at 45°C for 3 hours, lift out the asphalt to clean the surface, impregnate and then roast, the temperature of roasting is gradually raised from room temperature to 60...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com