Improved method for producing aluminium oxide by medium-low-grade bauxite

A low-grade bauxite and alumina technology, applied in the direction of alumina/hydroxide, etc., can solve problems such as complex process, not optimal lime addition, and no explanation of the relationship, so as to simplify the process and achieve better economic benefits Good, the effect of increasing the dissolution temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

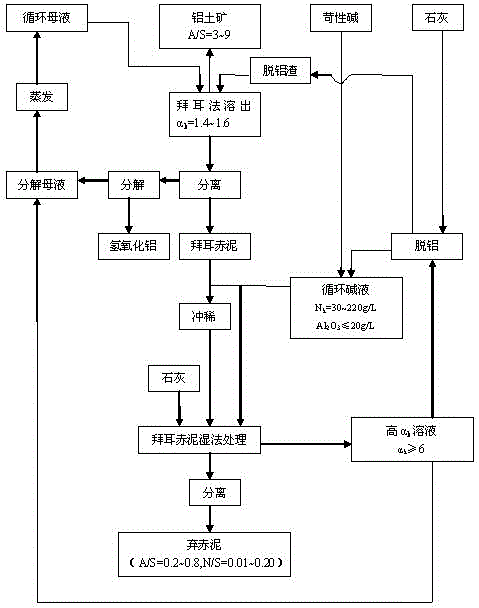

Method used

Image

Examples

Embodiment 1

[0018] The aluminum-silicon ratio A / S of bauxite is 3, the dissolution temperature of the Bayer method is 145°C, and the caustic alkali concentration of circulating lye is N k 140g / L, a K It is 3.0, and the dealuminated slag produced in the regeneration process of circulating alkaline solution is used as the stripping additive with Bayer process red mud wet method, and the stripping time is 90min, and the stripping liquid a K The aluminum-silicon ratio of dissolved red mud is 1.48, the ratio A / S of dissolved red mud is 1.5; the Bayer process red mud wet treatment temperature is 180°C, the concentration of circulating lye is 190g / L, the calcium-silicon ratio of the total lime addition is 1.6, and the Bayer process part accounts for 20 %, wet treatment of red mud accounts for 80%, the dissolution time is 120min, the aluminum-silicon ratio A / S of the dissolved red mud is 0.5, and the sodium-silicon ratio N / S is 0.08.

Embodiment 2

[0020] The aluminum-silicon ratio A / S of bauxite is 4, the dissolution temperature of the Bayer method is 100°C, and the caustic alkali concentration of the circulating lye is N k is 230g / L, a K 3.0, dissolution time 240min, dissolution liquid a K The aluminum-silicon ratio of the dissolved red mud is 1.50, and the ratio A / S of the dissolved red mud is 1.4; the Bayer method red mud wet treatment temperature is 160°C, the concentration of the circulating lye is 190g / L, the calcium-silicon ratio of the total lime addition is 1.2, and the Bayer method part accounts for 10 %, the wet treatment of red mud accounts for 90%, the dissolution time is 150min, the aluminum-silicon ratio A / S of the dissolved red mud is 0.60, and the sodium-silicon ratio N / S is 0.10.

Embodiment 3

[0022] The aluminum-silicon ratio A / S of bauxite is 5, the dissolution temperature of the Bayer method is 145°C, and the caustic alkali concentration of the circulating lye is N k 180g / L, a K is 3.0, the dissolution time is 30min, and the dissolution liquid a K The aluminum-silicon ratio of dissolved red mud is 1.50, the ratio A / S of dissolved red mud is 1.30; the Bayer process red mud wet treatment temperature is 200°C, the concentration of circulating lye is 160g / L, the calcium-silicon ratio of the total lime addition is 1.8, and the Bayer process part accounts for 20 %, wet treatment of red mud accounts for 80%, the dissolution time is 80min, the aluminum-silicon ratio A / S of the dissolved red mud is 0.65, and the sodium-silicon ratio N / S is 0.04.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com