Magnetic tuned filter with magnetic circuit air gap field fine tuning structure and debugging method

An air-gap field and magnetic tuning technology, which is applied to waveguide devices, circuits, electrical components, etc., can solve the problems of inconsistent resonant frequency of resonant balls, failure to meet technical index requirements, and low production efficiency, so as to improve technical index, Improve production efficiency, reduce the effect of standing wave matching and synchronous matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

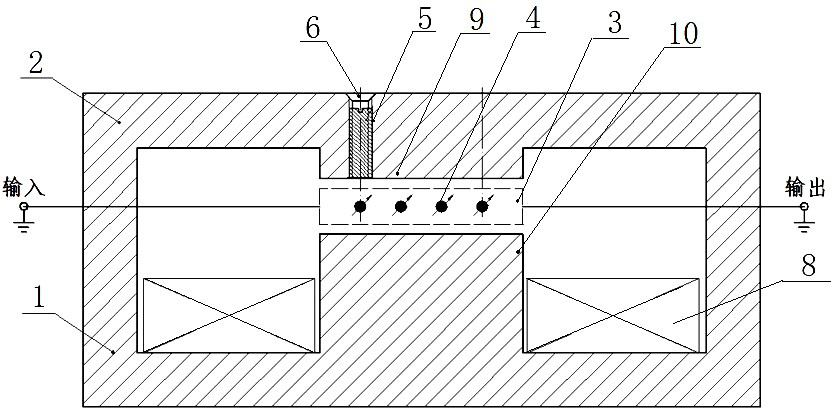

[0043] Example 1: see Figure 1-Figure 5 ,and Figure 10 , a magnetic tuning filter with a magnetic circuit air gap field fine-tuning structure, including an upper magnetic circuit 2 and a lower magnetic circuit 1, the upper magnetic circuit 2 is provided with an upper magnetic pole 9, and the lower magnetic circuit 1 is provided with a lower magnetic pole 10, A working air gap is arranged between the upper magnetic pole 9 and the lower magnetic pole 10, and a resonant circuit 3 is arranged between the working air gaps. The small ball adjusting rod 7 of the small ball 4, the resonant small balls 4 at both ends are the input and output small balls, and the middle one is the inter-stage small ball;

[0044] It is characterized in that: when there are three resonant balls 4, the upper magnetic pole 9 is vertically provided with a through screw hole 5 at the position corresponding to the interstage ball, and a fine adjustment screw 6 is arranged in the through screw hole 5;

[0...

Embodiment 2

[0060] Example 2: see Image 6 , Figures 7a-7c , a magnetic tuning filter with a magnetic circuit air gap field fine-tuning structure, the resonant balls 4 are three, and the rest are the same as the magnetic tunable filter with a magnetic circuit air-gap field fine-tuning structure in Embodiment 1.

[0061] Its debugging method is:

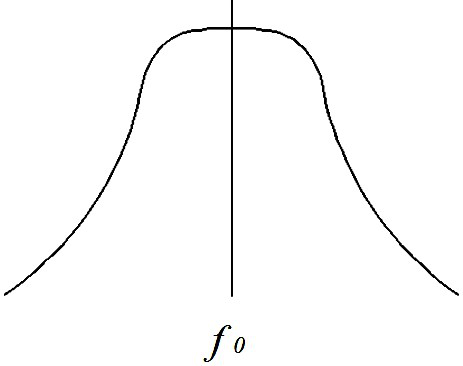

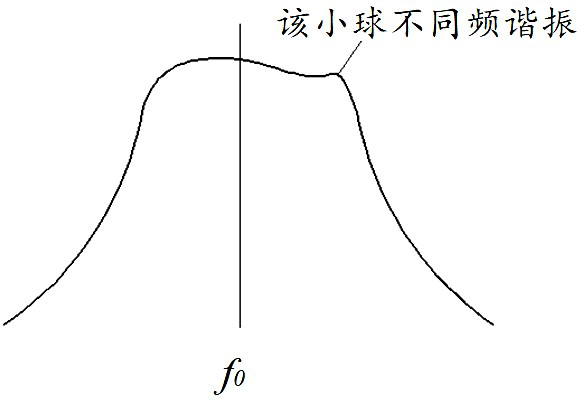

[0062] (1) Connect the product to be debugged to an appropriate amount of network analyzer equipment, and the operating frequency of the low-frequency end of the product is f 1 , the operating frequency of the high-frequency end is f 2 , adjust the coupling degree of each resonant ball 4 so that f 1 or f 2 At least one place satisfies the resonant frequency of all resonant balls 4 to be the same, and the response waveform is normal, see Figure 7a .

[0063] (2) Judgment f 1 or f 2 Whether the response waveforms are normal, in this embodiment, f 1 The response waveform at is normal, f 2 The response waveform at is not normal,...

Embodiment 3

[0067] Example 3: see Figure 8 , Figures 9a-9c , a magnetic tuning filter with a magnetic circuit air gap field fine-tuning structure, its resonant balls 4 are six, only two fine-tuning screws 6 are set at the input and output ball positions, and the rest are the same as the magnetic circuit in Example 1. The magnetic tuning filter structure of the air gap field fine-tuning structure is the same.

[0068] Its debugging method is:

[0069] (1) Connect the product to be adjusted into the vector network analyzer equipment, if the operating frequency of the low-frequency end of the device is f 1 , the operating frequency of the high-frequency end is f 2 , adjust the coupling degree of each resonant ball 4 so that f 1 or f 2 At least one place satisfies the resonant frequency of all resonant balls 4 to be the same, and the response waveform is normal, see Figure 9a ;

[0070] (2) Judgment f 1 or f 2 Whether the response waveforms are normal, in this embodiment, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com