Red mud separating washing technology with self circulation and its device

A self-circulating red mud technology, applied in the purification of alumina/aluminum hydroxide, aluminate/aluminum oxide/aluminum hydroxide, etc., can solve the problem of low feed liquid-solid ratio, very large evaporation workshop, washing Problems such as large amount of water added, to achieve the optimization of system technical indicators, solve the problem of red mud washing, and ensure the effect of normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

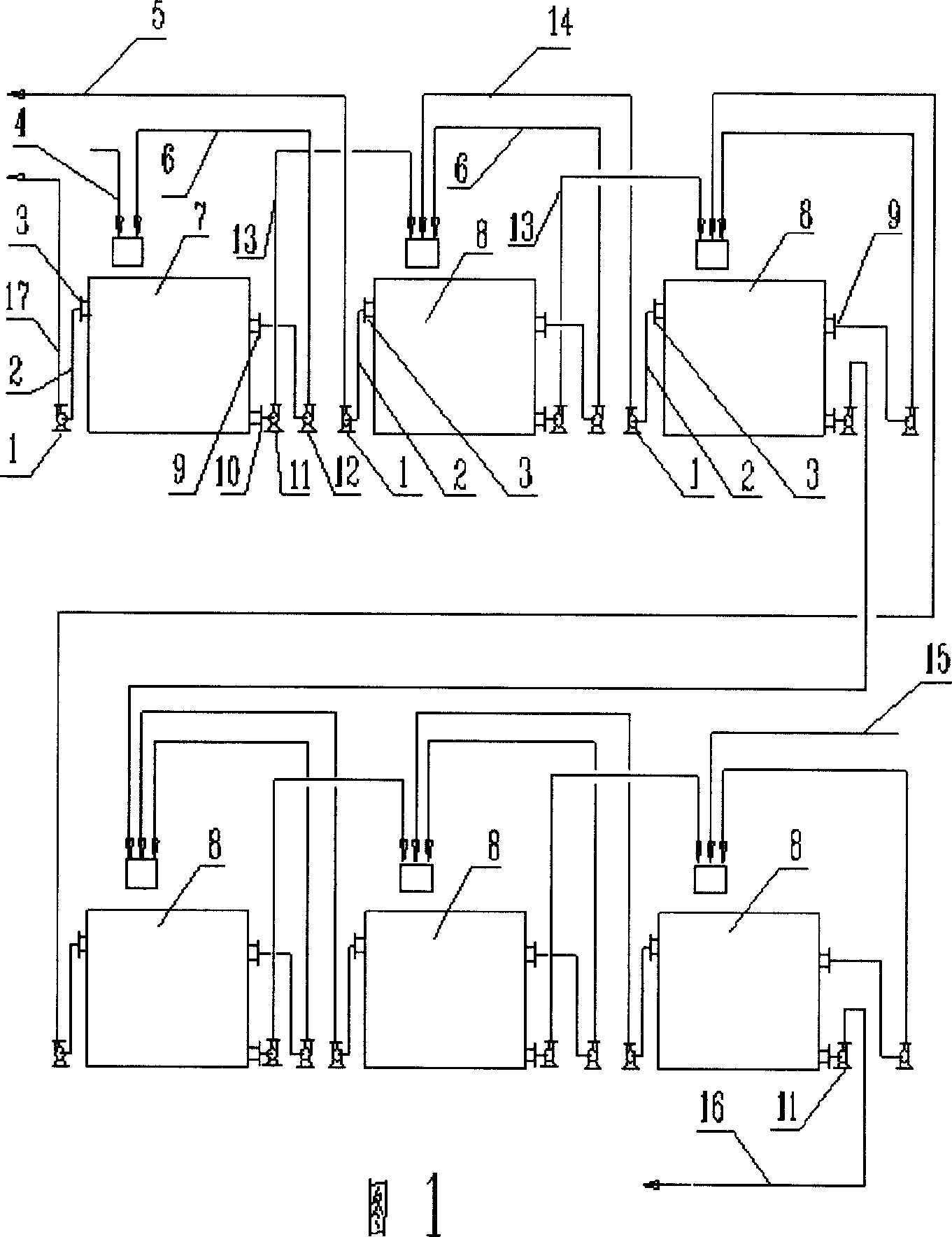

[0017] Implementation example of the present invention: during implementation, implement according to the following method: promptly improve on the basis of the separation settling tank, washing settling tank and backwash structure adopted in the existing conventional red mud separation and washing process, first in each Add a solution outlet on the separation settling tank and washing settling tank respectively, and add a pump next to the tank bottom of the separating settling tank and washing settling tank, connect the solution outlets of each tank with its pumps respectively with pipelines, and The solution discharged from the solution outlet is sent back to the tank at the solution outlet to form a self-circulation structure, so that 10% to 60% of the solution in each separation settling tank and washing settling tank participates in self-circulation, and is backwashed in a conventional way Through the backwashing structure, the washing liquid is sent to the previous settli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com