Magnetic memory method and device for diagnosing ferromagnetic component damage

A technology of ferromagnetic components and diagnostic methods, applied in the direction of material magnetic variables, etc., can solve the problems of inconvenient online detection and achieve the effect of convenient online detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The method discloses a magnetic memory diagnosis method for damage to a ferromagnetic component 7. The surface of the component is scanned by an array of magnetic induction sensors 1, the leakage magnetic field on the surface of the component is tested, and the measured magnetic signal is converted into an electrical signal, which is amplified by filtering and A After the / D conversion process, it is input to the processor 3, and the component surface test signal information is obtained through the processor 3, so as to obtain whether a certain area of the component is in a state of imminent damage or no damage, and finally displayed on the display 5. The process of the processor 3 to obtain the surface test signal information of the component, so as to obtain whether a certain area of the component is in an imminent damage state or not in a damage state specifically refers to: the signal input to the processor 3 after being processed by A / D conversion is the Hp sign...

Embodiment 2

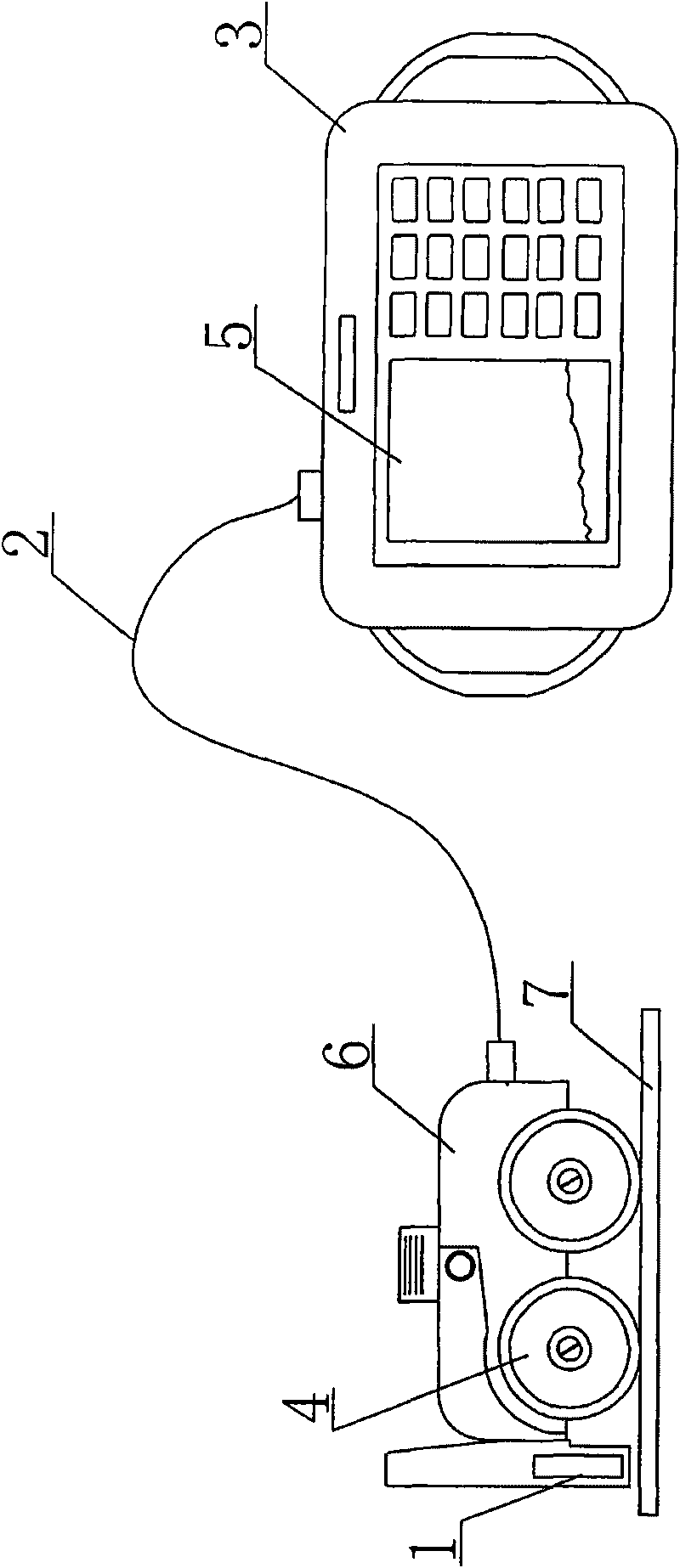

[0027] Refer to the attached figure 1 , the device includes an array scanning ferromagnetic member 7 surface, and the magnetic induction sensor 1 that converts the measured magnetic signal into an electrical signal, is connected with the magnetic induction sensor 1 and obtains the length measurement sensor 4 of the scanning distance signal, and the magnetic induction sensor 1 and the length The measuring sensor 4 is connected with a filter for filtering and processing the electric signal and the distance signal, and an amplifier for amplifying processing, and the filter and the amplifier are cascaded, connected with the filter and the amplifier and performing analog processing on the filtered and amplified signal. An A / D conversion module for digital conversion, a processor 3 connected to the A / D conversion module to process the signal, and a display 5 for displaying the signal processing result. The magnetic induction sensor 1 , the length measurement sensor 4 , the filter an...

Embodiment 3

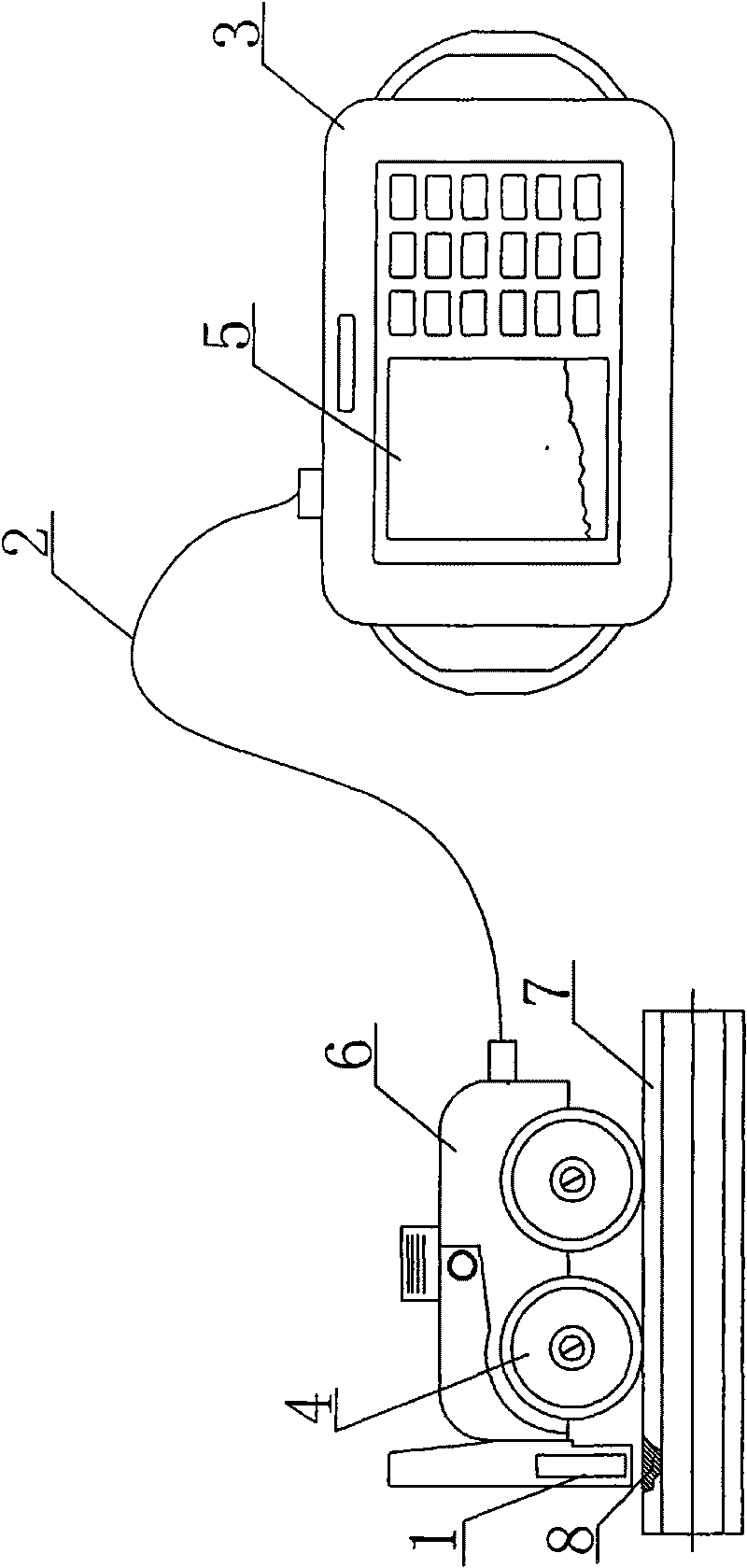

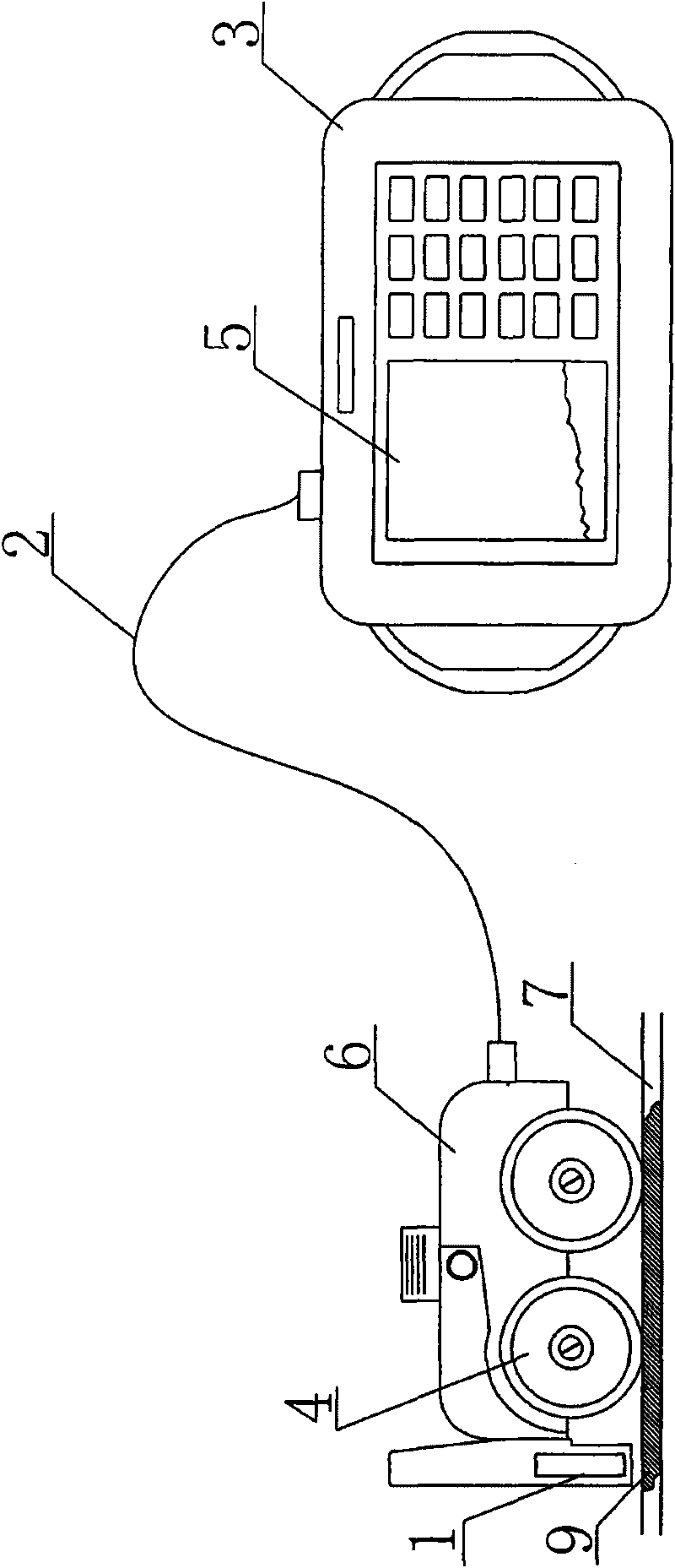

[0029] A certain type of mud high-pressure manifold magnetic memory diagnostic test such as figure 2 As shown, it includes a magnetic induction sensor 1 and a length measuring sensor 4; a signal transmission line 2; a processor 3 and a display 5. The magnetic induction sensor 1, the length measurement sensor 4, the signal filter and the amplifier are all integrated on the detection trolley 6 and placed on the pipeline surface together. The magnetic induction sensor 1 and the processor 3 are connected by a signal transmission cable. During detection, the magnetic memory detection car 6 scans the pipeline surface quickly, and the defect 8 on the surface and inside of the pipeline or the leakage magnetic field in the stress concentration area overflows the pipeline body, is received by the scanned magnetic induction sensor 1, and passes through the filter in the detection car 6 and an amplifier to filter and amplify the signal and transmit it to the processor 3 for processing. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com